Capabilities Ability

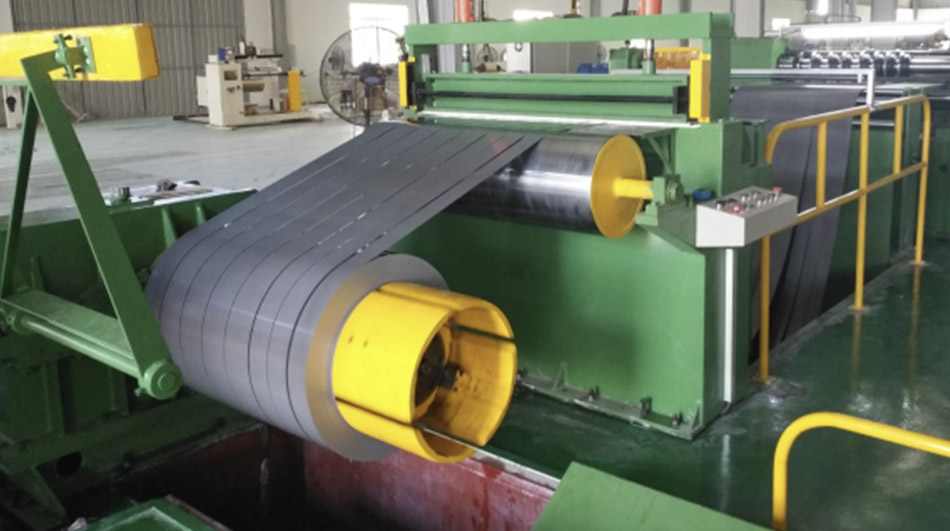

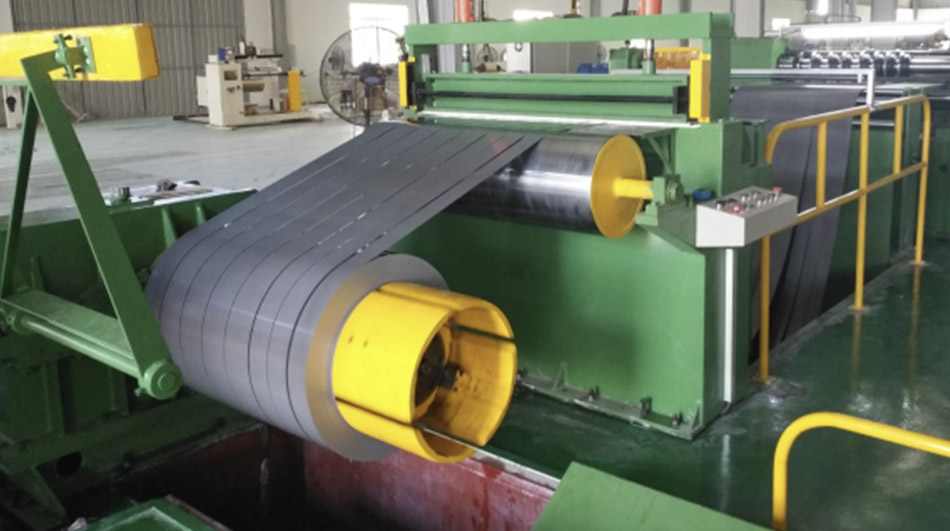

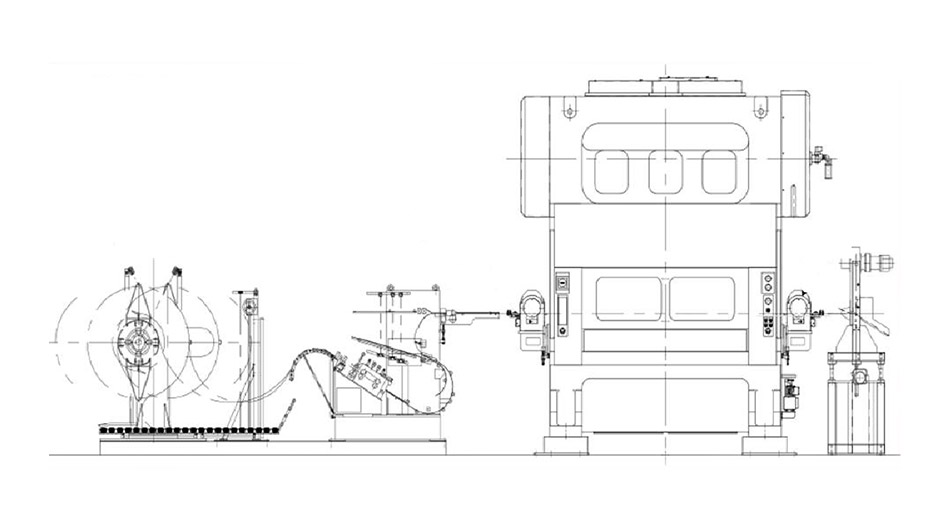

Slitting (Longitudinal Shearing)

. Precision slitting;

. Cutting to length;

. Blanking

Total Land Area

Annual Consumption of steel

Employees

. Precision slitting;

. Cutting to length;

. Blanking

. IPG laser generator

. High repeat positioning accuracy-0.01mm.

. Quick response: 7 days sampling lead-time.

. QTY: 5 sets.

. 110 set press with range from 16T-400T;

. Low die cost;

. Short lead time for die development, less than 30 days for mass production;

. Supporting sampling demand;

. Low cost solution from material usage with swinging feeder;

. Fulfill low and middle volume demand.

. Low-cost solution for large parts;

. Short lead time.

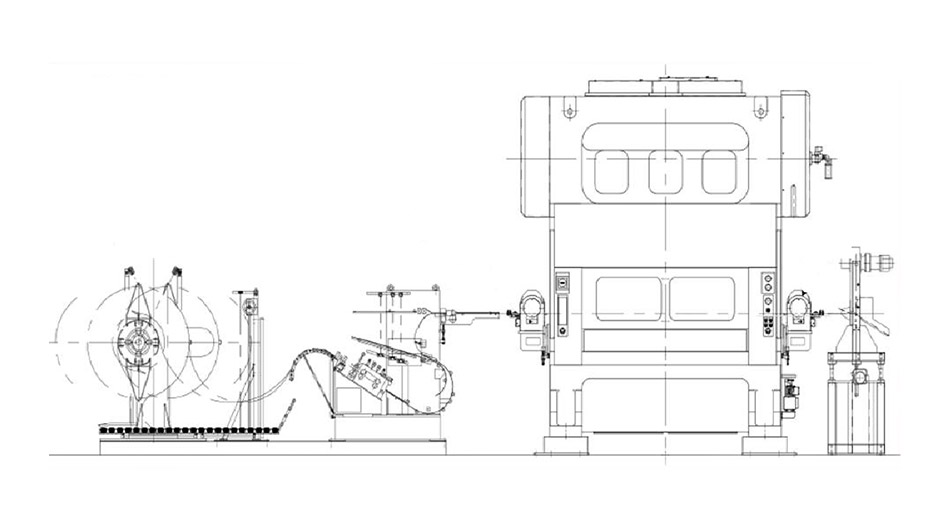

· Over 30 high-speed presses

·Tonnage: 200-400 tons

·Table size: 1.2M-3.7M

· 3.7-meter-long table size high-speed presses offer multi-cavity stamping solutions for large-size stamping parts

Slitting (Longitudinal Shearing)

Slitting (Longitudinal Shearing)

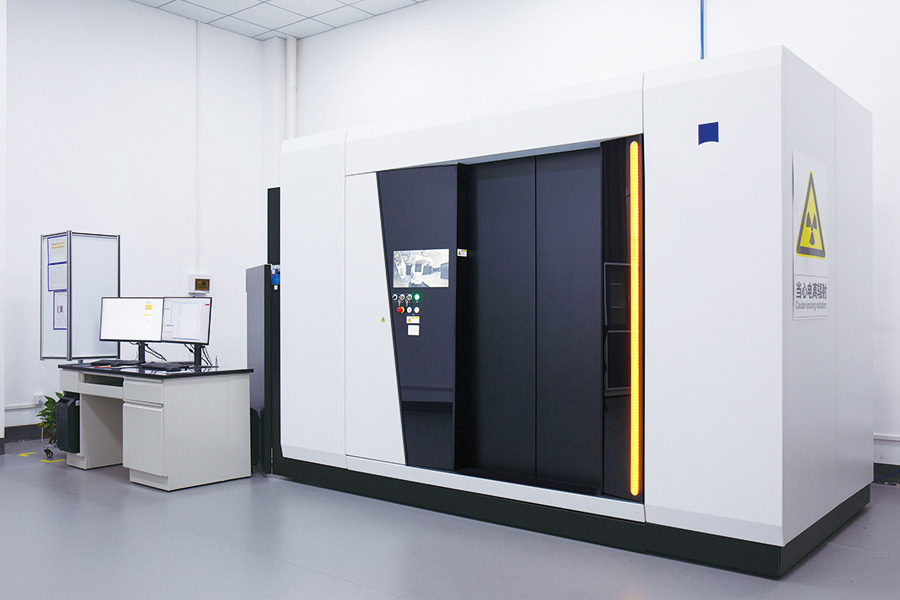

Laser Cutting

Laser Cutting

Compound Stamping (General Stamping)

Compound Stamping (General Stamping)

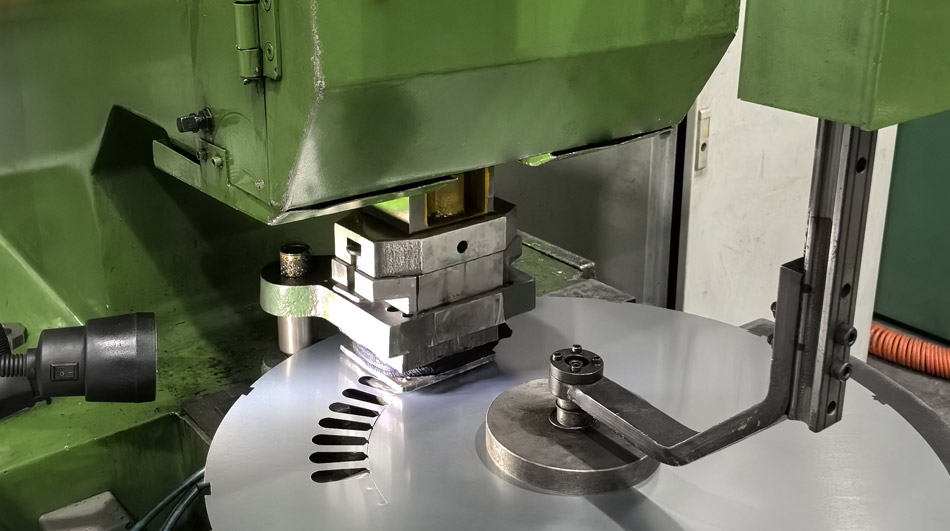

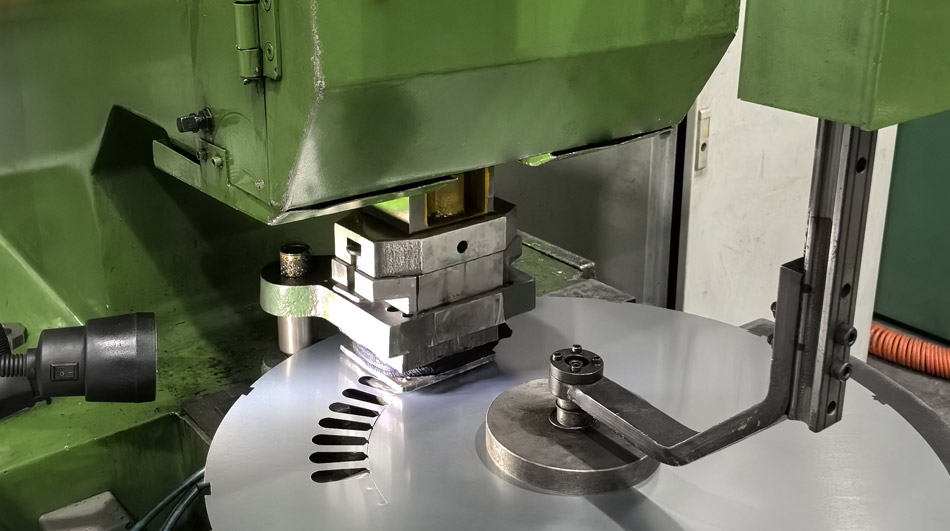

Notching

Notching

High-Speed Progressive Stamping

High-Speed Progressive Stamping

. Over 15 die casting machines to meet various application needs

. Horizontal automatic die casting machines with a tonnage range of 280T to 560T

. Vertical vacuum die casting machine with a tonnage of 200T

. Vertical die casting machines capable of switching between copper and aluminum alloys

· Multi-channel operation

· Automatic height measurement

· Automatic groove-type detection

· Automatic pressurization

· Automatic marking

· Automatic scanning and quality inspection

· Automatic dust removal and rust prevention

· Automatic sorting and data traceability

· Each high-speed stamping production line is equipped with an automatic rotor line.

· Over 25 fully automated stator welding lines, equipped with capabilities such as weighing, critical dimension measurement, visual comparison inspection of weld seams, automatic slot foreign object inspection, automatic coding, automated sorting, and data traceability.

· Stator laser welding station

· Robotic TIG (Tungsten Inert Gas) welding station

· Rotary multi-station TIG welding machine station

· Meet the personalized needs of products with different batch sizes

Offers processes such as stator clipping, riveting, and manual self-clinching for lamination. It employs traditional to advanced stator pressing methods, including mechanical pressing and servo press pressing. This approach not only provides low-cost engineering solutions for sample and small-batch product delivery but also offers highly precise and customized engineering solutions to meet diverse customer needs.

Stator winding workshop;

Manual winding and automatic winding, with a production capacity of 100,000 units.

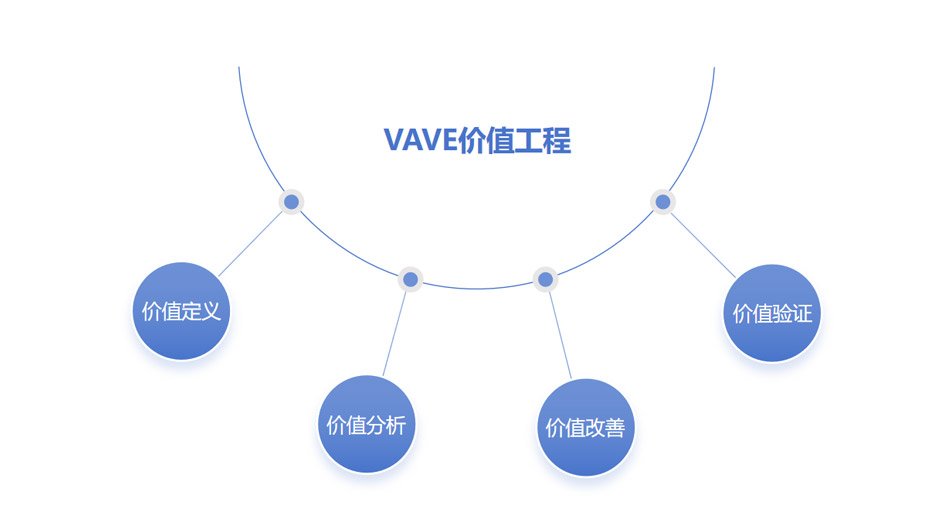

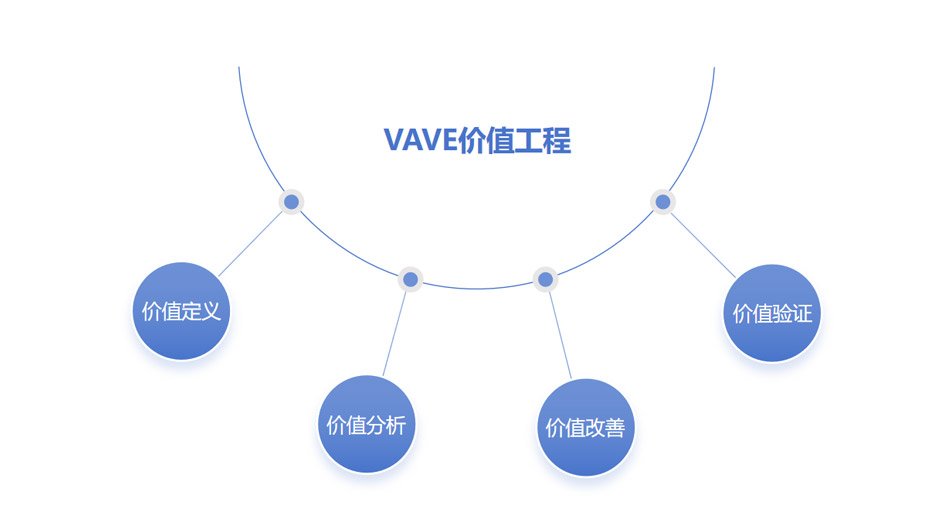

Jufeng helps customers achieve the goals of reducing costs, improving efficiency, enhancing market competitiveness, and promoting technological innovation through value definition, analysis, improvement, and verification in various aspects such as product design, production processes, and material selection.

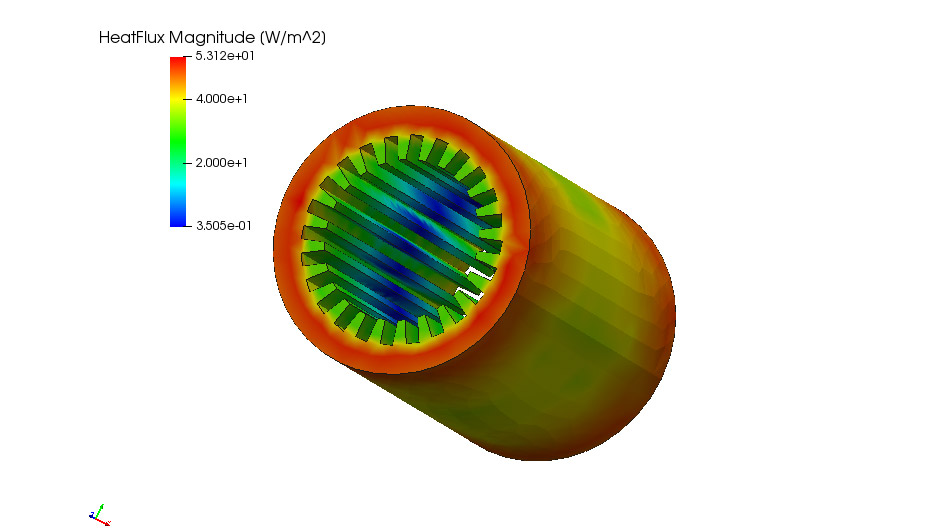

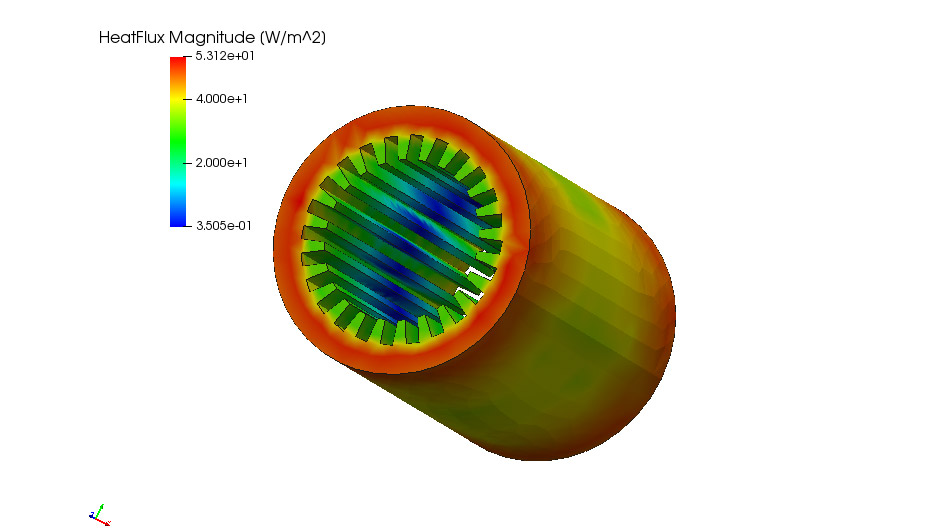

Jufeng offers FEA (Finite Element Analysis) services, which aim to analyze the electromagnetic, mechanical, and thermal performance of stator and rotor cores using the finite element method. This helps customers reduce costs, increase efficiency, and enhance their competitiveness in the market.

Die Casting

Die Casting

Automatic Rotor Line

Automatic Rotor Line

Stator Welding

Stator Welding

Stator Pressing

Stator Pressing

Stator Winding

Stator Winding

VAVE

VAVE

FEA

FEA

Jufeng Technology, with its extensive database of silicon steel performance samples, has a profound technical accumulation in the field of electrical steel. It provides precise support for motor design, ensuring optimized design and avoiding excess. It can select high-quality performance within the same grade, enhancing the efficiency of the motor.

Jufeng Technology has been deeply involved in the stamping field for a long time, accumulating a wealth of experience and developing various stamping engineering solutions such as compound stamping, oscillating stamping, single-slot stamping, and high-speed progressive stamping. These solutions can meet the requirements of different batch sizes, precision levels, and delivery times, providing customers with efficient and accurate stamping services.

Jufeng Technology, leveraging its desirable motor design capabilities, has successfully developed a series of high-efficiency motors and obtained multiple patents. The company's core design has achieved serialization and standardization, meeting high-performance requirements while effectively controlling costs, making it a reliable value support for motor customers.

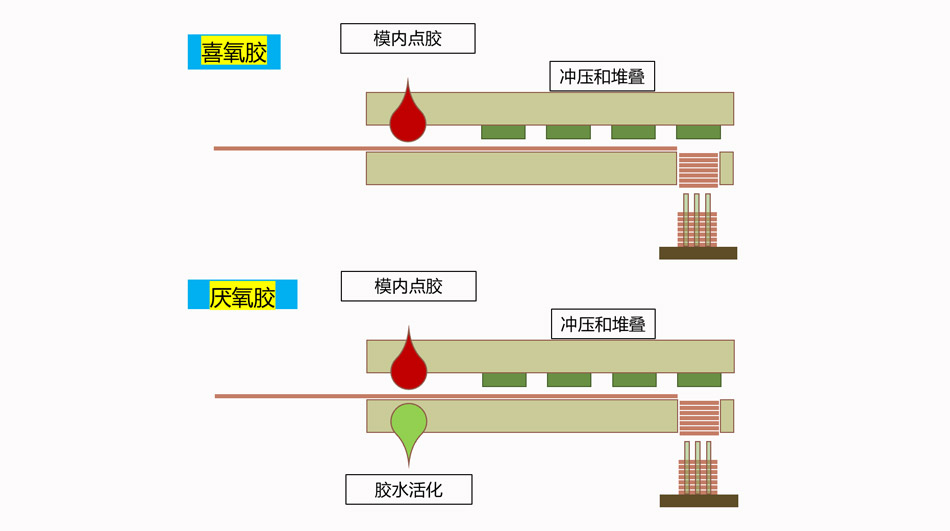

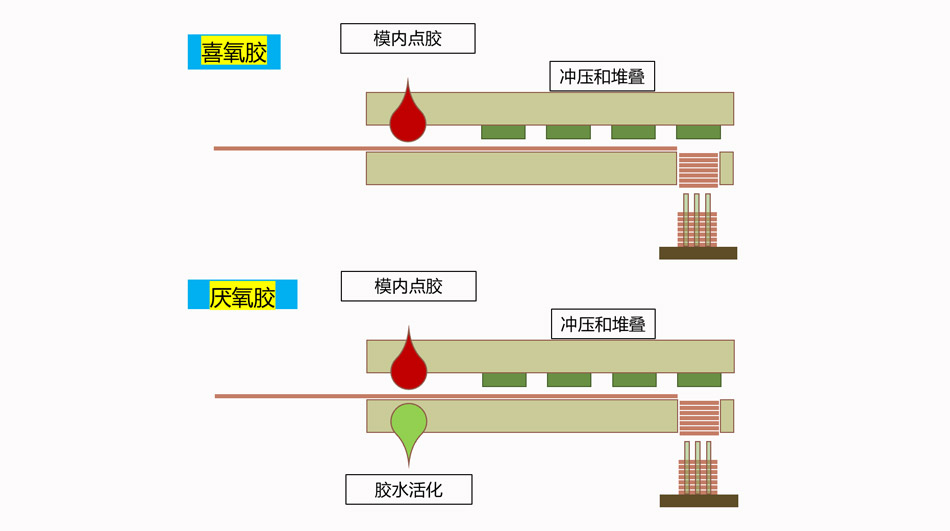

Jufeng Technology has developed post-molding gluing, in-mold gluing, and self-adhesive processes to meet the varying batch and application needs of motor cores. By optimizing production, they have increased efficiency and reduced costs, achieving a balance between comprehensive costs and motor efficiency, bringing significant technological advancements and economic benefits to motor manufacturing.

The annealing process for silicon steel stampings can release pressing stress, promote the optimization and growth of grains, effectively dull burrs, and significantly enhance electromagnetic performance. This process optimizes the material structure by accurately controlling the heating and cooling processes, reducing iron loss, and improving energy efficiency, demonstrating desirable performance in the vast majority of motor applications.

Material Selection

Material Selection

Stamping Technology Development

Stamping Technology Development

Motor Core Design

Motor Core Design

Glue Lock

Glue Lock

Annealing

Annealing

Add: 369 Huanzhen East Road, Changle Town, Shengzhou City, Zhejiang Province, China

Add: No. 1007 East Huanzhen Road, Changle Town, Shengzhou City, Zhejiang Province,China

Add: No.555 Wenhe Road, Economic Development Zone, Tongxiang City, Jiaxing City, Zhejiang Province, China

Zhejiang Jufeng Technology Co., Ltd. © All rights reserved