Automotive Motor Stator and Rotor Cores: A Comprehensive Guide

What are Stator and Rotor Cores?

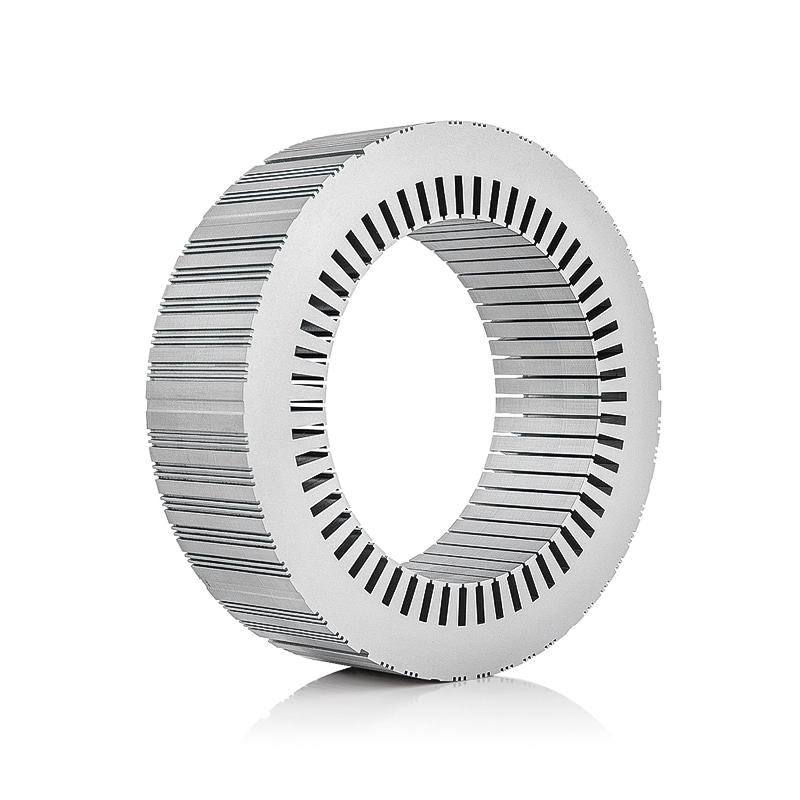

Stator Cores

A stator core is the stationary component of an electric motor. It's the part that houses the copper windings, which, when an electric current passes through them, generate a magnetic field. This magnetic field then interacts with the rotor, causing it to spin. Stator cores are typically constructed from a stack of thin sheets of laminated steel or, for more complex designs, from soft magnetic composites (SMC).

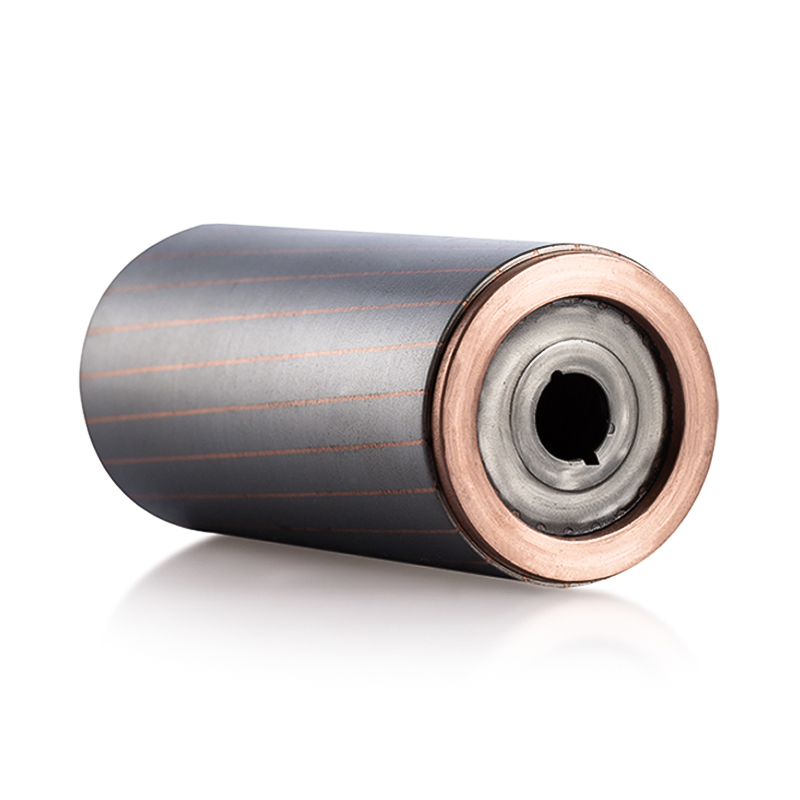

Rotor Cores

The rotor core is the rotating component of the motor. It's designed to interact with the magnetic field produced by the stator. This interaction creates the torque that drives the motor's shaft. Depending on the motor type, the rotor core may contain permanent magnets or be a simple stack of laminated steel that becomes an electromagnet when a current is induced in its windings. Like stators, rotor cores are also made from laminated steel or SMC.

Materials Used in Stator and Rotor Cores

Laminated Steel Grades

Laminated steel, also known as electrical steel or silicon steel, is a crucial material for stator and rotor cores in electric motors. It is specifically engineered to have properties that minimize energy loss in the form of heat, which is vital for motor efficiency.

- Silicon Steel: This is the most common type of laminated steel. The addition of silicon to the iron increases its electrical resistivity, which significantly reduces eddy current losses. These are circular currents induced within the core material that generate heat and waste energy.

- Non-Oriented (NO) Steel: The magnetic properties of this steel are roughly the same in all directions. This makes it ideal for applications where the magnetic flux changes direction, as is the case in the rotating magnetic field of an electric motor.

Properties & Applications

- Properties: High magnetic permeability (ability to concentrate magnetic fields) and low core loss (energy loss due to hysteresis and eddy currents).

- Applications: Widely used in hybrid and electric vehicle motors due to their excellent balance of performance and cost.

Soft Magnetic Composites (SMC)

Soft Magnetic Composites (SMC) are a class of materials made from insulated iron powder. The iron particles are coated with a thin insulating layer, and then compacted into a solid component using powder metallurgy.

- Composition: Fine iron powder coated with a thin, electrically insulating material.

- Properties: SMCs have isotropic magnetic properties, meaning their magnetic characteristics are the same regardless of the direction of the magnetic field. This allows for the creation of complex, three-dimensional shapes that are difficult or impossible to make with laminated steel. SMCs also have extremely high electrical resistivity, which virtually eliminates eddy current losses.

- Applications: They are particularly well-suited for high-speed motors and applications with complex geometries, where the ability to create intricate 3D flux paths is a major advantage.

Other Materials

While laminated steel and SMC are the primary materials, other materials are used in specific niche applications.

- Ferrites: These are ceramic-based materials made from iron oxides and other metallic elements. They have very high resistivity, which translates to extremely low eddy current losses, especially at high frequencies. However, their lower magnetic permeability and saturation flux density limit their use in high-power applications.

- Amorphous Alloys: These are non-crystalline, metallic materials with excellent soft magnetic properties. They offer exceptionally low core loss but are more expensive and challenging to manufacture into complex shapes, which limits their widespread use in automotive motors.

Manufacturing Processes

Stamping and Lamination

The most common method for manufacturing stator and rotor cores from laminated steel is stamping and lamination. This process involves creating thin, individual layers, or laminations, and then stacking them to form the core.

- Process: A high-speed press uses a precision die to stamp thin sheets of electrical steel. These individual laminations have intricate patterns with slots for windings. The laminations are then stacked and secured together using various methods, such as welding, interlocking, or bonding.

- Advantages: This method is highly suitable for high-volume production and is generally very cost-effective for large-scale manufacturing. The process is well-established, reliable, and can achieve tight tolerances.

- Considerations: A significant initial investment is required for tooling costs, as the dies are complex and expensive to produce. There is also material waste in the form of scrap from the stamping process, although efforts are made to optimize the layout of the stampings to minimize this.

Powder Metallurgy (PM)

Powder metallurgy is a manufacturing process used to create complex parts from metal powders. It's particularly well-suited for manufacturing cores from Soft Magnetic Composites (SMC).

- Process: Finely powdered metal (usually iron) is mixed with an insulating binder and then compacted under high pressure in a die. The resulting "green" part is then sintered, a process that involves heating the part to a temperature below the melting point of the metal. This fuses the particles together, creating a solid, porous component.

- Advantages: Powder metallurgy allows for the creation of complex, three-dimensional shapes that are not possible with stamping. It is a net-shape manufacturing process, meaning it produces parts very close to their final shape with little to no material waste, which can lead to significant cost savings.

- Considerations: The cost of the metal powder and the need for precise control of the sintering process are key factors. The resulting parts may have lower mechanical strength compared to laminated steel cores, and the process is typically slower than high-speed stamping.

Winding and Assembly

Once the stator and rotor cores are manufactured, the next step is to insert the windings. This is a critical process that directly impacts the motor's performance.

- Process: Copper or aluminum wires are precisely wound and then inserted into the slots of the stator core. This can be done through a variety of methods, including fly winding, needle winding, or linear winding.

- Automated vs. Manual: Automated winding systems offer high precision, consistency, and speed, which is essential for high-volume production. Manual winding is more suitable for prototyping or low-volume applications, but it is less precise and more labor-intensive. The choice between these two methods is a balance of cost and precision requirements.

Performance Factors

The performance of an automotive motor core is determined by several key factors. These properties are critical for maximizing motor efficiency, power density, and durability.

Magnetic Permeability

- Definition: Magnetic permeability is a material's ability to support the formation of a magnetic field within itself. A material with high permeability can concentrate magnetic field lines, making the magnetic circuit more efficient.

- Impact: In a motor, higher magnetic permeability means that a stronger magnetic field can be generated with less electrical current. This directly improves motor efficiency and allows for a more compact and lightweight design for a given power output.

Core Loss

- Definition: Core loss is the energy lost as heat within the magnetic core when it is subjected to a changing magnetic field. It is comprised of two main components:

- Hysteresis Loss: Occurs when the magnetic domains within the material reorient themselves in response to a changing magnetic field. This process requires energy and generates heat.

- Eddy Current Loss: Caused by small, circular electrical currents (eddy currents) that are induced within the core material by the changing magnetic field. These currents generate heat due to the material's electrical resistance.

- Impact: Lower core loss is critical for motor performance. It reduces heat generation, which not only improves efficiency but also reduces the need for extensive cooling systems, thereby decreasing the overall size and weight of the motor.

Mechanical Strength

- Definition: Mechanical strength refers to the core's ability to withstand mechanical stresses and forces without deforming or breaking. This includes both static forces from assembly and dynamic forces from high-speed rotation and vibration.

- Impact: High mechanical strength ensures the durability and reliability of the motor core. It prevents damage during manufacturing, handling, and operation, especially in harsh automotive environments with significant vibration and shock.

Thermal Conductivity

- Definition: Thermal conductivity is a material's ability to conduct or transfer heat. In a motor core, it determines how effectively heat generated from core losses and windings can be dissipated to the cooling system.

- Impact: Efficient heat dissipation is vital for preventing overheating. High thermal conductivity allows heat to be quickly moved away from the core, keeping the motor within its optimal operating temperature range. This prevents material degradation and maintains consistent performance over the motor's lifespan.

Applications in Automotive Motors

The selection of materials and manufacturing processes for stator and rotor cores is highly dependent on the specific application within the automotive industry. Different types of vehicles and motors have distinct performance requirements.

Electric Vehicle (EV) Motors

For a pure electric vehicle, the motor is the primary power source. Therefore, the stator and rotor cores must be optimized for maximum efficiency, high power density, and low weight to extend the vehicle's range and improve its performance.

- Stator and Rotor Core Requirements: High efficiency is paramount to conserve battery power. The cores must also have excellent thermal management capabilities to handle sustained high-power operation. Low weight is also critical to improve the vehicle's overall energy consumption.

- Material Selection: Laminated steel, particularly non-oriented silicon steel, is the most common choice due to its high magnetic permeability and low core loss. In some advanced designs, Soft Magnetic Composites (SMC) are being explored for their ability to create complex 3D flux paths, which can further increase power density.

Hybrid Vehicle (HV) Motors

Hybrid vehicles use a combination of an internal combustion engine and an electric motor. The electric motor often operates in a highly dynamic manner, providing power for acceleration, regenerative braking, and low-speed driving.

- Stator and Rotor Core Requirements: Hybrid motors require a high power density and reliable performance across a wide range of operating conditions. The cores must be able to withstand frequent starts and stops and handle significant torque variations.

- Material Selection: Advanced laminated steel with very low core losses and high saturation flux density is typically used. This allows the motor to be compact and powerful, seamlessly integrating with the vehicle's powertrain.

Other Automotive Applications

Stator and rotor cores are not limited to the main traction motors of EVs and HVs. They are also found in various other auxiliary automotive systems where electric motors are used.

- Starter Motors: The cores in starter motors are designed for high torque output over a very short duration. They are typically made from laminated steel to handle the high current and magnetic flux.

- Power Steering Motors: Electric power steering (EPS) systems use motors with cores that are optimized for precise control and quiet operation.

- Auxiliary Motors: This category includes motors for windshield wipers, power windows, seat adjustments, and other components. These motors are generally smaller and the cores are designed for reliability and cost-effectiveness rather than extreme performance.

Trends and Future Developments

The field of automotive motor core technology is continuously evolving, driven by the demand for higher efficiency, increased power density, and more sustainable manufacturing practices. Key trends are focused on new materials, advanced manufacturing, and sophisticated design optimization.

Advanced Materials

Research and development are focused on creating materials that surpass the performance of traditional silicon steel.

- High-Performance Alloys: Manufacturers are developing new alloys with improved magnetic properties. These alloys are designed to have even lower core losses and higher magnetic saturation, which directly translates to a more efficient motor that can operate at higher power levels without excessive heat generation.

- Nanomaterials: The use of nanomaterials, such as nanocrystalline alloys, presents a promising frontier. These materials have a unique atomic structure that can significantly enhance soft magnetic properties, offering the potential for even greater energy efficiency and power density in future motors.

Improved Manufacturing Techniques

Innovations in manufacturing processes are crucial for reducing costs and enabling more complex core designs.

- Additive Manufacturing (3D Printing): Additive manufacturing, or 3D printing, is being explored for creating motor cores. This technology could allow for the production of highly complex geometries that are impossible to achieve with traditional stamping. This could lead to optimized flux paths and a significant reduction in material waste.

- High-Precision Stamping: While stamping is a mature technology, ongoing improvements focus on increasing precision and efficiency. Advancements in die design and stamping presses are helping to reduce material waste and allow for the production of thinner laminations, which further minimizes eddy current losses.

Optimization and Simulation

Sophisticated software tools and computational methods are becoming indispensable for designing and optimizing motor cores.

- Finite Element Analysis (FEA): Engineers use Finite Element Analysis (FEA) to simulate and optimize core designs. FEA software can accurately predict a core's magnetic, thermal, and mechanical performance. This allows for rapid prototyping and virtual testing, enabling engineers to refine designs for peak performance before any physical prototypes are made.

- AI and Machine Learning: Artificial intelligence (AI) and machine learning are being applied to analyze vast datasets related to material properties and manufacturing processes. These technologies can help predict the behavior of new materials, optimize manufacturing parameters to reduce defects, and even suggest novel core designs that would be difficult for human engineers to conceptualize.

Types of Automotive Motor Stator and Rotor Cores

This section of your article will cover the different types of automotive motor cores, which can be categorized based on the material used in their construction. The choice of core type is a fundamental design decision that impacts the motor's performance characteristics.

Laminated Steel Cores

Laminated steel cores are the most widely used type in the automotive industry, particularly for electric vehicle (EV) and hybrid vehicle (HV) traction motors. They are made by stacking thin sheets of silicon steel, or "laminations," on top of each other.

- Structure and Function: The thin laminations are electrically insulated from one another to prevent the flow of eddy currents. These currents, if allowed to form, would generate heat and cause significant energy loss. By breaking up the potential path for these currents, lamination dramatically reduces core loss and improves efficiency.

- Key Characteristics:

- High Power Density: Laminated steel can handle high magnetic flux densities, allowing for powerful and compact motor designs.

- Low Core Loss: Especially when made with non-oriented silicon steel, these cores are designed for minimal energy loss under the rapidly changing magnetic fields in a motor.

- Anisotropic Properties: The magnetic properties of laminated steel are strongest along the direction of lamination, which can be a key consideration in design.

Soft Magnetic Composite (SMC) Cores

Soft Magnetic Composite (SMC) cores represent a more recent technological advancement, offering unique advantages for specific motor designs. They are created using powder metallurgy from insulated iron particles.

- Structure and Function: Unlike laminated steel, SMC cores are made from a three-dimensional block of material. The individual iron particles are coated with an insulating layer, which effectively eliminates eddy currents at a microscopic level. This allows for complex, three-dimensional shapes that can't be made with traditional stamping.

- Key Characteristics:

- Isotropic Properties: The magnetic properties are uniform in all directions, which is ideal for motors with complex, three-dimensional magnetic flux paths.

- Complex Geometries: SMCs can be molded into intricate shapes with a process that produces little to no material waste, known as net-shape manufacturing.

- Very Low Eddy Current Loss: Due to the excellent insulation between particles, SMC cores have extremely low eddy current losses, which is a major advantage in high-frequency applications. However, they may have higher hysteresis losses compared to optimized laminated steel.

- Lower Magnetic Saturation: SMCs generally have a lower maximum magnetic flux density compared to laminated steel, which can sometimes limit their use in very high-power applications.

Parameter Comparison

| Parameter | Laminated Steel Cores | Soft Magnetic Composite (SMC) Cores |

|---|---|---|

| Magnetic Properties | Anisotropic (strongest along lamination) | Isotropic (uniform in all directions) |

| Core Loss | Low (primarily due to lamination) | Very low eddy current loss, but can have higher hysteresis loss |

| Manufacturing Process | Stamping and lamination | Powder metallurgy (molding and sintering) |

| Complexity of Shape | Limited to 2D stacked layers | Enables complex 3D geometries |

| Material Waste | Can be significant (scrap from stamping) | Minimal (near net-shape process) |

| Magnetic Saturation | High | Lower than laminated steel |

Installation Precautions

The installation of automotive motor stator and rotor cores is a precise process that directly affects the motor's performance, efficiency, and reliability. Correct installation not only ensures that the design performance is achieved but also prevents potential failures.

Cleaning and Inspection

Before installation, the stator and rotor cores must be thoroughly inspected and cleaned to ensure there are no impurities or damage.

- Cleaning: Ensure that the core surfaces are free from any dust, oil, metal shavings, or other contaminants. These impurities can affect the motor's insulation performance and even lead to short circuits. Use a lint-free cloth and an appropriate cleaning agent.

- Inspection: Carefully check the core laminations for looseness, deformation, or burrs. Even minor defects can increase vibration and noise, and affect magnetic properties, thereby reducing motor efficiency.

Insulation Treatment

The winding slots in the stator core must be well-insulated to prevent the copper wire windings from coming into direct contact with the core, which could cause a short circuit.

- Insulation Paper/Film: Before inserting the windings, a layer of insulation paper or film is typically placed in the slots. Ensure the insulation material is intact, undamaged, and precisely sized to fit the slot shape.

- Winding Impregnation: After the windings are installed, they are usually treated with a vacuum pressure impregnation (VPI) or dipping process. This process binds the windings and the core tightly together, filling all gaps, improving overall mechanical strength and thermal dissipation, while also enhancing insulation.

Tolerance and Alignment

The air gap between the stator and rotor is a critical parameter that affects motor performance. Precise fit and alignment are necessary to ensure efficient motor operation.

- Concentricity: During installation, the centerline of the rotor must be precisely aligned with the centerline of the stator core to ensure a uniform air gap between them. Any eccentricity will lead to unbalanced magnetic forces, causing vibration, noise, and reduced efficiency.

- Axial Position: Ensure that the rotor's axial position inside the stator is correct to guarantee that the magnetic field effectively covers the rotor, avoiding performance losses from end effects.

- Fit Tolerance: The fit tolerances between the stator core's outer diameter and the motor housing, and between the rotor core's inner diameter and the motor shaft, must meet design requirements. A fit that is too tight can damage components, while a fit that is too loose can compromise the connection's stability.

Parameter Comparison

| Installation Aspect | Impact | Potential Issues |

|---|---|---|

| Cleanliness | Insulation performance, thermal management | Localized overheating, insulation breakdown, short circuits |

| Lamination Integrity | Magnetic performance, vibration, noise | Reduced efficiency, increased core loss, shortened motor lifespan |

| Insulation Treatment | Electrical safety, reliability | Winding short circuit, insulation aging, heat accumulation |

| Concentricity | Running smoothness, efficiency | Vibration, noise, bearing wear, unstable performance |

| Fit Tolerance | Structural stability, heat dissipation | Component damage, loose connections, poor heat dissipation |

Maintenance Measures

Automotive motor stator and rotor cores are high-precision components. While they don't require the same frequent daily maintenance as traditional mechanical parts, regular inspection and proper maintenance are crucial for ensuring the motor's long-term reliability and performance.

Routine Inspection

Maintenance work primarily focuses on monitoring the motor's overall performance and conducting physical inspections to identify potential issues.

- Vibration Analysis: By regularly monitoring the motor's vibration levels, issues like rotor imbalance, bearing wear, or core loosening can be detected early. Increased vibration is often an early sign of an internal fault.

- Temperature Monitoring: Overheating is a primary threat to motor cores and windings. Continuously monitoring the motor's operating temperature, especially under load, can prevent insulation material aging, magnetic property degradation, and increased core loss.

- Noise Detection: Abnormal noises (e.g., high-pitched whistling, knocking sounds) may indicate loose core laminations, friction between the windings and the core, or bearing failure, requiring immediate inspection.

- Electrical Parameter Testing: Regularly performing electrical tests, such as insulation resistance tests and winding DC resistance tests, can assess the insulation state between the windings and the core, ensuring there are no short circuits or leakage.

Cooling System Maintenance

Good thermal management is key to protecting the motor core and windings.

- Coolant Check: For liquid-cooled motors, regularly check the coolant level, composition, and cleanliness. Ensure there are no leaks or contamination and that the coolant can effectively dissipate heat from the core and windings.

- Radiator Cleaning: Keep the radiator clean, preventing dust, dirt, or leaves from blocking the cooling fins, which would seriously impact heat dissipation efficiency.

- Fan Inspection: For air-cooled motors, check that the cooling fan is working properly, that the fan blades are undamaged, and that the air inlets and outlets are clear.

Troubleshooting and Repair

Once an issue with the core or windings is detected, appropriate repair measures must be taken.

- Loose Core Laminations: If vibration analysis or noise detection indicates loose core laminations, they may need to be re-tightened, for example, by re-riveting or welding. In severe cases, the entire stator or rotor assembly may need to be replaced.

- Winding Insulation Damage: If an insulation test fails, indicating damage to the winding insulation layer, the windings usually need to be replaced and re-impregnated with varnish. This is a complex and precise task that should be performed by a professional.

- Physical Damage: If the core is deformed due to a collision or abnormal operation, it is typically irreparable and must be replaced.

Parameter Comparison

| Maintenance Measure | Problems Prevented | Key Parameters |

|---|---|---|

| Vibration Analysis | Rotor imbalance, core loosening, bearing failure | Vibration amplitude, vibration frequency |

| Temperature Monitoring | Insulation aging, magnetic property degradation, increased core loss | Winding temperature, core temperature, coolant temperature |

| Electrical Parameter Testing | Insulation breakdown, winding short circuit, leakage | Insulation resistance (Ω), DC resistance (Ω) |

| Cooling System Maintenance | Overheating, heat accumulation, efficiency drop | Coolant level, coolant temperature, radiator clarity |

Common Failure Issues

Failures in automotive motor stator and rotor cores, while not as obvious as mechanical wear, are critical factors affecting a motor's performance, efficiency, and lifespan. Understanding these common failures helps in effective diagnosis and maintenance.

1. Increased Core Loss

Core loss is primarily composed of hysteresis loss and eddy current loss. When these losses increase abnormally, it leads to motor overheating and a drop in efficiency.

- Causes:

- Lamination Insulation Failure: If the insulation coating between the laminations of the stator or rotor core is damaged due to overheating or mechanical stress, it can create short circuit paths, leading to a sharp increase in eddy currents.

- Manufacturing Defects: During production, if the lamination stamping creates burrs or if the insulation layer is damaged during assembly, it can cause inter-lamination short circuits.

- Prolonged Overheating: Continuous high temperatures can accelerate the aging of insulation materials, eventually leading to insulation failure.

- Impact:

- Efficiency Drop: More electrical energy is converted into heat rather than mechanical energy.

- Motor Overheating: The generated heat may exceed the cooling system's design capacity, further accelerating insulation aging.

2. Lamination Loosening and Vibration

If the core laminations cannot be kept tightly stacked, it can lead to severe mechanical and electrical problems.

- Causes:

- Improper Assembly: If the stator core is pressed into the motor housing or the rotor core onto the shaft with uneven or excessive pressure, it can cause the laminations to deform or loosen.

- Thermal Cycling: Motors undergo repeated heating and cooling, and the difference in thermal expansion coefficients of different materials can lead to stress accumulation, which over time can loosen the laminations.

- High-Frequency Vibration: Resonance generated at high speeds or under specific operating conditions can cause the inter-lamination connections (e.g., welding or riveting) to fail.

- Impact:

- Noise and Vibration: Loose laminations will generate noise and high-frequency vibrations under the influence of the magnetic field, damaging the bearings.

- Mechanical Damage: Vibration can cause winding insulation wear, even short circuits with the core.

- Reduced Magnetic Performance: The increased air gap between laminations affects the magnetic flux path, thereby reducing motor performance.

3. Winding-to-Core Short Circuit

Insulation breakdown between the winding and the core is one of the most common and critical motor failures.

- Causes:

- Insulation Aging: The winding insulation material deteriorates due to long-term overheating, moisture, or chemical contamination.

- Mechanical Damage: Scratches to the winding during installation, or friction between the winding and the core caused by vibration.

- Excessive Electrical Stress: Voltage spikes or surges may exceed the insulation material's tolerance, leading to a breakdown.

- Impact:

- Winding Burnout: A short circuit can generate a massive current and heat, rapidly burning out the windings.

- Motor Failure: This typically causes the motor to stop working completely, requiring major repair or replacement.

Parameter Comparison

| Failure Type | Typical Parameter Changes | Primary Impact |

|---|---|---|

| Increased Core Loss | Increased Temperature Rise, Efficiency Drop | Overheating, increased energy consumption |

| Lamination Loosening | Increased Vibration Level, Increased Noise | Bearing damage, mechanical stress, potential electrical failure |

| Winding-to-Core Short Circuit | Decreased Insulation Resistance, Abnormal Current | Motor failure, complete shutdown, serious safety hazard |

简体中文

简体中文 English

English русский

русский Español

Español