Applications of Electric Vehicle Generator Motor Cores in Various Sectors

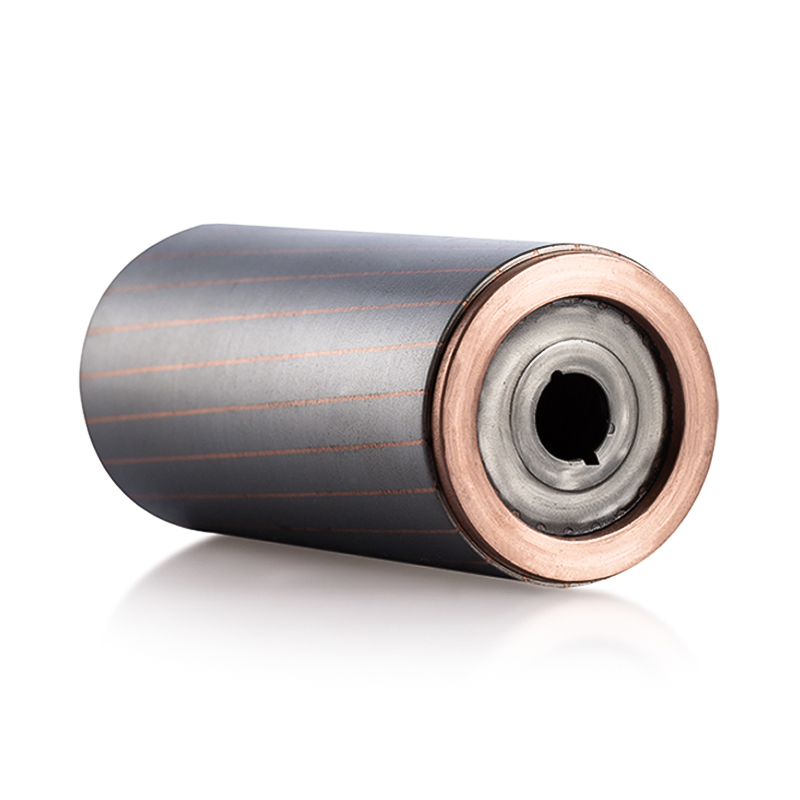

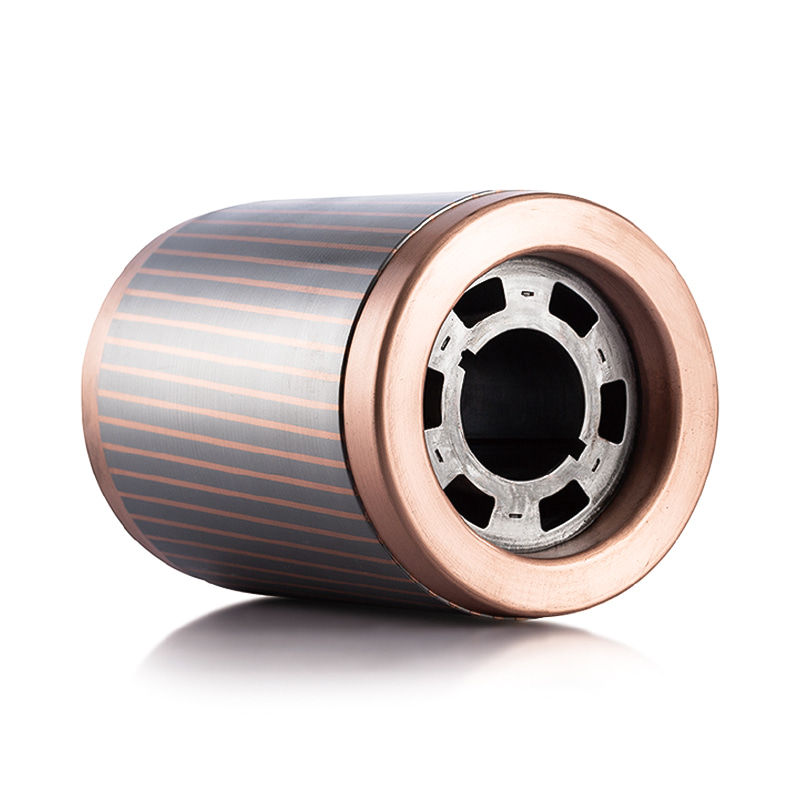

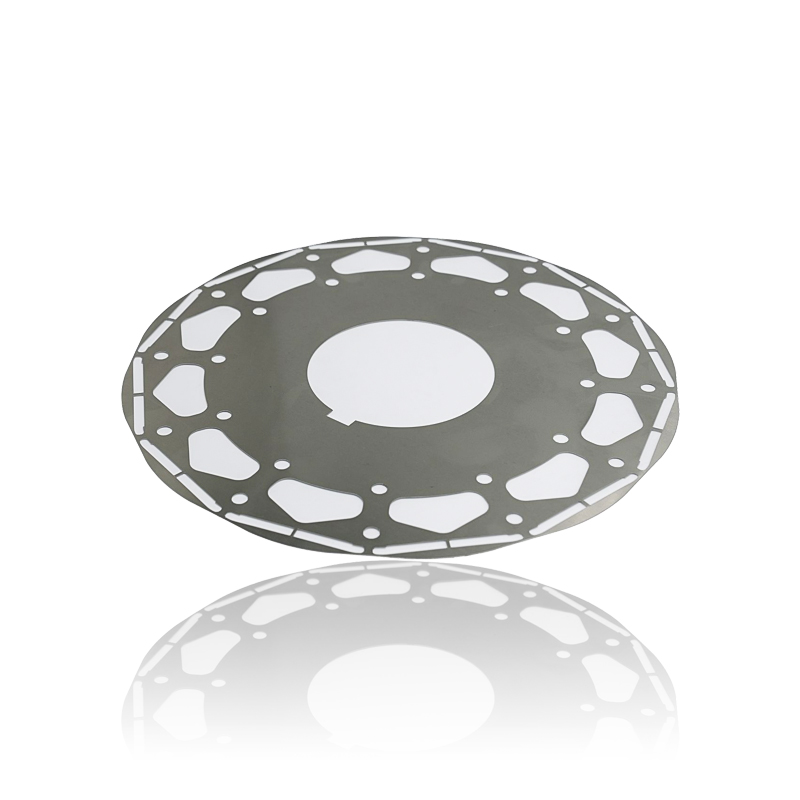

Electric vehicles (EVs) are increasingly becoming the preferred mode of transport due to their environmentally friendly nature and energy efficiency. The performance of these vehicles heavily relies on high-performance generator motor cores, as they power the drive motors that convert electrical energy from the battery into mechanical power for the vehicle’s movement. The stator and rotor cores work together in generating the electromagnetic fields needed to drive the motor, and the efficiency of these components directly influences the EV's range, speed, and overall driving experience. The role of motor cores in EVs cannot be overstated. High-quality stator and rotor cores reduce energy loss, optimize torque delivery, and help in balancing the vehicle’s overall power consumption. This is particularly critical as the global push for cleaner and more energy-efficient transportation grows. With battery technology also advancing, improving the performance of motor cores ensures that vehicles can operate with longer battery life, reduced maintenance, and better reliability. Zhejiang Jufeng Technology Co., Ltd. has been a trusted supplier of electric vehicle generator motor cores, offering state-of-the-art stator and rotor components designed to improve EV motor performance. Our high-efficiency motor cores help reduce the overall weight and enhance the power output, contributing significantly to the development of electric cars with superior range and reduced carbon footprints. By integrating advanced materials and manufacturing techniques, we ensure that our motor cores meet the increasing demand for high-performing electric vehicle technologies. As EV adoption accelerates globally, we expect the demand for advanced motor cores to rise, pushing the boundaries of innovation in the electric vehicle sector. With Jufeng’s continuous focus on R&D, we are poised to support this transformation by providing the most reliable and efficient motor cores that power the next generation of electric vehicles.

Wind power is one of the most promising renewable energy sources in the world. Wind turbines generate electricity by converting the kinetic energy from wind into mechanical energy through their rotors, which then drives a generator. In this process, electric vehicle generator motor cores are used to ensure that the turbine operates with maximum efficiency. The stator and rotor cores in these systems play a critical role in generating the electromagnetic fields required to convert mechanical energy into electrical power, which is then fed into the grid. The materials and design of the motor cores used in wind turbines are crucial in ensuring long-term performance and efficiency. These motor cores must withstand harsh environmental conditions such as high winds, extreme temperatures, and saltwater corrosion. They also need to be highly durable to reduce maintenance and extend the operational life of the turbines. Stator and rotor cores made from advanced materials, such as high-grade electrical steel or permanent magnets, ensure that wind turbines operate at their optimal efficiency for extended periods. At Zhejiang Jufeng Technology Co., Ltd., we have extensive experience supplying motor cores for the wind power generation sector. Our advanced manufacturing processes ensure that our stator and rotor cores offer minimal energy loss and enhanced magnetic performance, crucial for improving the energy output of wind turbines. Our products have been integrated into wind power generation systems worldwide, and our commitment to quality ensures that turbines powered by our motor cores run efficiently, reducing operational costs while maximizing energy generation. As the global shift toward renewable energy accelerates, the need for efficient, high-performance motor cores in wind turbines becomes even more apparent. Our efforts to innovate and improve the materials used in our motor cores will continue to support the growth of wind power as a sustainable and reliable energy source.

The rail transit industry is gradually transitioning towards electric propulsion as part of a broader push to reduce emissions and enhance operational efficiency. Electric trains rely on high-performance motors to provide the power needed for both passenger and freight transportation. Electric vehicle generator motor cores are central to this shift, enabling trains to operate more efficiently and sustainably. The stator and rotor cores of these motors are responsible for generating the electromagnetic fields that create torque, which drives the train’s wheels. In rail systems, the efficiency of these motor cores has a direct impact on the performance of the trains. High-quality motor cores help ensure that trains can accelerate smoothly, maintain high speeds, and operate with minimal energy consumption. The durability of these cores is essential for minimizing maintenance and ensuring long-term operational reliability in challenging environments, such as varying terrains and climates. Zhejiang Jufeng Technology Co., Ltd. has played an integral role in providing reliable motor cores for rail transit systems. Our stator and rotor cores are designed for optimal performance and longevity, helping operators reduce operational costs and energy usage. As global demand for electric trains and eco-friendly transit solutions grows, we are committed to supporting the rail industry with our advanced motor core technology. With rail systems expanding in cities worldwide and increasing efforts to adopt electric locomotives, the demand for high-efficiency motor cores will continue to rise. Our expertise in this field positions us to meet the evolving needs of the rail transit industry, providing components that help achieve the goal of sustainable and efficient public transportation.

The rise of industrial automation and robotics has revolutionized manufacturing and production across many sectors. Robots are used for a variety of tasks, from assembly and packaging to precision machining and quality control. In these applications, electric vehicle generator motor cores are essential for powering the robotic motors that drive these systems. The stator and rotor cores in robotic motors provide the necessary torque, speed, and precision to allow robots to perform their tasks with high accuracy and efficiency. The use of motor cores in industrial robots demands high-performance characteristics, including the ability to handle rapid movements, continuous operation, and high mechanical loads. Motor cores must be optimized for performance, weight, and energy consumption to ensure that the robots operate at peak efficiency without overloading the system or consuming excessive energy. This is particularly crucial in industries where high-speed production is required, such as electronics manufacturing, automotive production, and logistics. At Zhejiang Jufeng Technology Co., Ltd., we have developed motor cores that meet the demanding specifications of the industrial robotics sector. Our stator and rotor cores are designed to maximize power output while minimizing size and weight, making them ideal for integration into compact robotic systems. With our advanced motor cores, robots can operate more efficiently, increasing productivity, reducing downtime, and enhancing precision in manufacturing processes. As industries continue to embrace automation, the demand for high-performance motor cores in robotics is expected to grow. By providing reliable and efficient motor cores, we contribute to the continued advancement of industrial robotics, improving the speed, accuracy, and reliability of these automated systems.

Electric Vehicle Generator Motor Rotor Cores are also widely used in household appliances, where they help power a variety of devices such as refrigerators, washing machines, dishwashers, and vacuum cleaners. The stator and rotor cores in these appliances are responsible for driving the motors that perform essential tasks like cooling, washing, and cleaning. The efficiency of these motor cores directly influences the energy consumption of the appliances, as well as their performance and durability. Energy efficiency is a key consideration in the design and manufacturing of household appliances, and motor cores play a significant role in achieving this goal. By using high-efficiency materials and optimizing the design of stator and rotor cores, appliance manufacturers can reduce the overall energy consumption of their products. This is especially important in the context of rising energy costs and increasing consumer demand for environmentally friendly and energy-efficient appliances. At Zhejiang Jufeng Technology Co., Ltd., we specialize in manufacturing motor cores that meet the stringent requirements of the household appliance industry. Our stator and rotor cores are designed to ensure smooth operation, energy efficiency, and longevity, making them ideal for use in a wide range of home appliances. By providing these high-performance motor cores, we help appliance manufacturers create products that deliver superior performance while minimizing energy use. As consumers continue to prioritize energy-efficient appliances, the role of motor cores in improving appliance performance and reducing environmental impact will become even more important. Our products help shape the future of the household appliance industry by enabling the development of smarter, more sustainable devices.

Electric Vehicle Generator Motor Rotor Cores are also finding applications in renewable energy systems beyond wind power, including hydroelectric power generation. In both large-scale and small-scale hydroelectric systems, electric motors powered by high-efficiency motor cores are used to generate electricity. These systems rely on the rotational motion of turbines, which are powered by water flowing through dams or other waterways, to generate mechanical energy that drives a generator. As with wind turbines, the motor cores used in hydroelectric power generation must be durable, efficient, and capable of operating in harsh environmental conditions. High-efficiency stator and rotor cores help maximize the energy conversion rate, ensuring that the system operates with minimal losses. The durability of these cores is critical to minimizing maintenance and maximizing the lifespan of the power generation systems. Zhejiang Jufeng Technology Co., Ltd. manufactures motor cores that are specifically designed for use in hydroelectric power systems. Our motor cores help optimize the performance of these renewable energy systems, ensuring that they operate efficiently and reliably. As the global push for renewable energy grows, the need for efficient motor cores in hydroelectric and other green energy systems will continue to rise.