How does the lamination thickness of a Wind Power Generator Motor Stator Core impact core losses and overall performance?

-

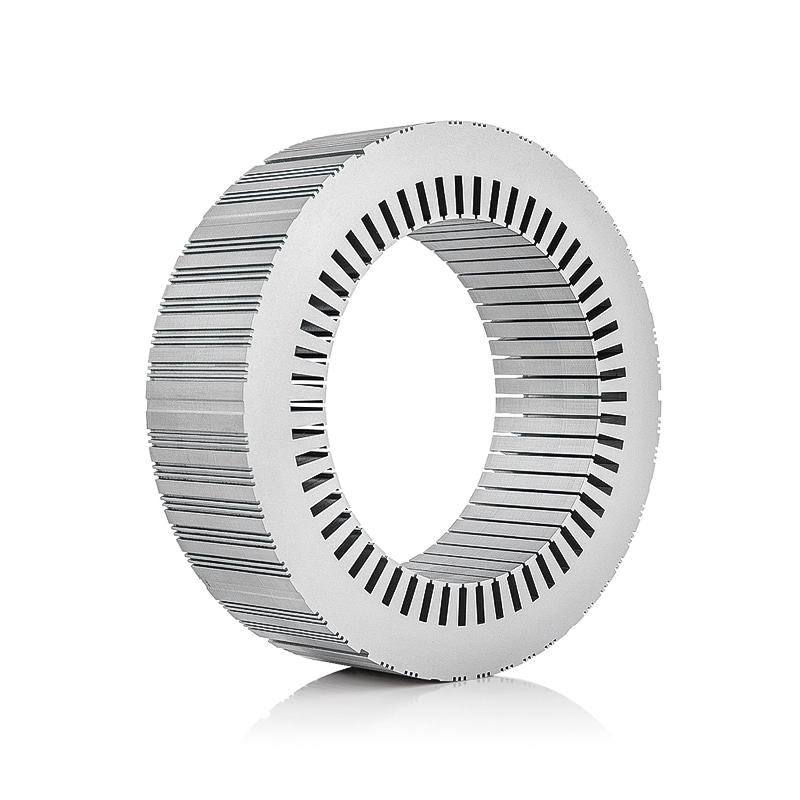

Core Loss Mechanisms in the Stator Core: The stator core of a wind power generator experiences energy losses primarily through hysteresis and eddy current effects, which are inherent to the operation of ferromagnetic materials under alternating magnetic fields. Hysteresis loss occurs as the magnetic domains within the core material repeatedly align and realign with the changing magnetic flux, consuming energy in the form of heat. Eddy current loss arises from the induced circulating currents generated by time-varying magnetic fields, which flow within the conductive core laminations and also produce heat. Both types of losses reduce the overall electrical efficiency of the generator, generate unwanted thermal stresses, and can accelerate material degradation. In wind turbines, where power output fluctuates due to variable wind speeds, understanding and minimizing these losses is crucial for maintaining consistent performance and prolonging equipment lifespan, particularly in high-capacity offshore installations where maintenance is costly and complex.

-

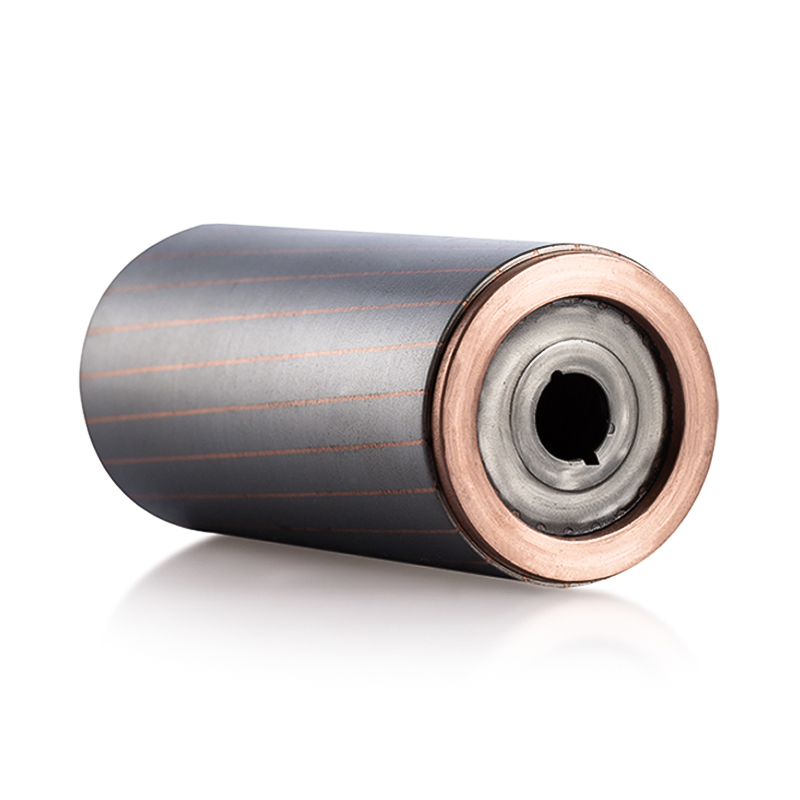

Effect of Lamination Thickness on Eddy Current Loss: Eddy current losses in a stator core are highly sensitive to lamination thickness, as the induced currents circulate within the conductive plane of each lamination. The loss magnitude is proportional to the square of the lamination thickness, the square of the magnetic flux density, and the square of the operating frequency. Thinner laminations break the paths for circulating currents, effectively limiting eddy currents and significantly reducing associated thermal losses. This reduction in eddy current loss is particularly important in variable-speed wind generators, where magnetic field fluctuations occur at higher frequencies, leading to stronger currents in thicker cores. Selecting an optimal lamination thickness requires careful analysis, balancing loss reduction with mechanical integrity, manufacturing tolerances, and the added cost associated with handling and insulating thinner steel laminations. Proper lamination design directly influences the overall generator efficiency and operational stability.

-

Impact on Hysteresis Loss: Hysteresis loss in a Wind Power Generator Motor Stator Core depends primarily on the material’s intrinsic magnetic properties and the peak magnetic flux density experienced during operation. While lamination thickness does not directly change the hysteresis loss, it plays an indirect but important role in maintaining the core’s thermal equilibrium. Thinner laminations reduce eddy current-generated heat, lowering the overall operating temperature of the core. Since elevated temperatures can adversely affect the magnetic properties of silicon steel or other core materials—such as reducing magnetic permeability and increasing coercivity—reducing temperature rise helps preserve hysteresis characteristics over time. By controlling thermal conditions through optimized lamination thickness, engineers can ensure the stator core maintains low hysteresis loss, avoids demagnetization issues under fluctuating wind loads, and improves long-term efficiency and reliability of the generator.

-

Influence on Generator Efficiency: The lamination thickness directly influences the electrical efficiency of a wind power generator. Thinner laminations reduce both eddy current and indirectly hysteresis losses, meaning that a greater proportion of the mechanical energy from the turbine rotor is converted into usable electrical energy. This efficiency gain is particularly significant at partial load conditions, which are common in wind energy systems where wind speed varies continuously. Reducing losses also lowers the temperature rise within the generator, enhancing winding insulation performance and preventing premature degradation of the core material. The improved efficiency has both operational and economic benefits, including increased energy yield, reduced operational costs, and higher return on investment. Engineering the optimal lamination thickness is therefore a critical step in generator design to maximize performance under variable environmental and operational conditions.

-

Thermal Performance and Reliability: Optimizing lamination thickness in a Wind Power Generator Motor Stator Core has a direct impact on thermal management, as it limits internal heat generation caused by eddy currents. Lower core temperatures reduce thermal stress on the stator windings, insulation systems, and the core material itself, which directly improves the reliability and operational lifespan of the generator. Excessive heat can lead to insulation breakdown, mechanical deformation of laminations, and accelerated aging of core steel. By minimizing heat through thin laminations, generators can maintain stable operating conditions even under fluctuating load and ambient temperature conditions, which is critical in offshore and high-altitude wind turbine installations. Proper thermal performance also ensures that protective systems such as temperature sensors and cooling mechanisms operate within their designed range, enhancing safety and reducing unscheduled maintenance.

简体中文

简体中文 English

English русский

русский Español

Español