How does the magnetic flux density of a Wind Power Generator Motor Stator Core affect generator efficiency?

-

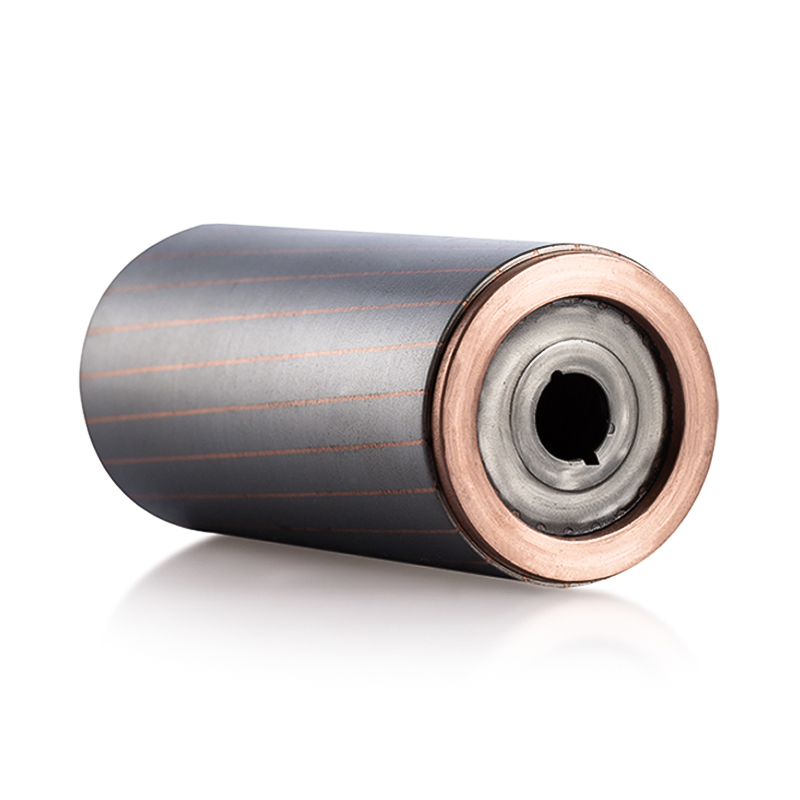

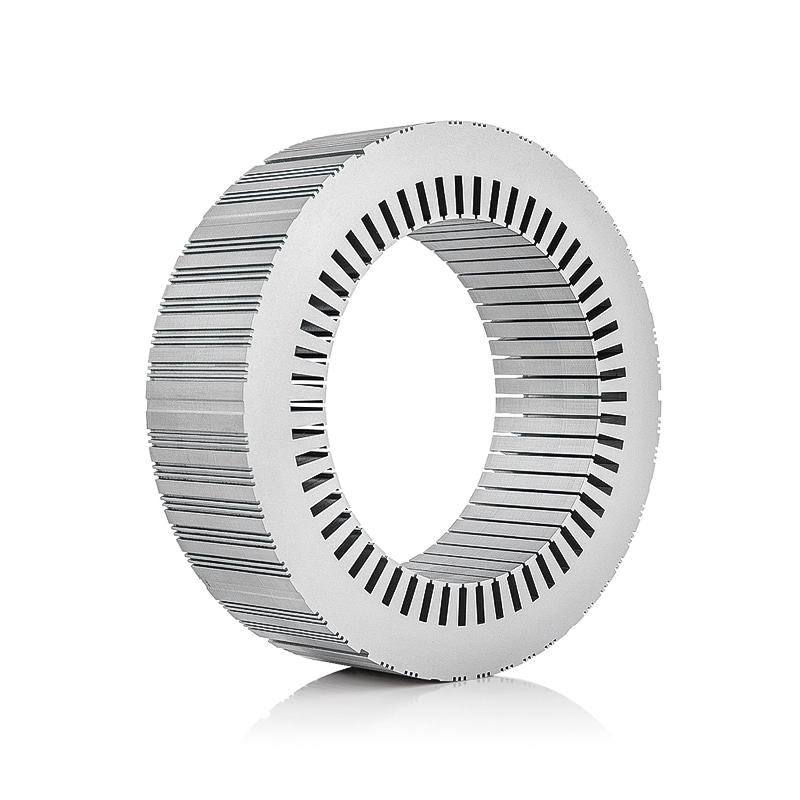

Fundamental Role of Magnetic Flux Density: Magnetic flux density (B) in Wind Power Generator Motor Stator Core is a fundamental parameter that determines the strength of the magnetic field within the stator core and the effectiveness of energy conversion from mechanical to electrical form. Higher flux density allows the core to store and transfer more magnetic energy, generating stronger electromotive forces in the stator windings. This directly translates into higher voltage output and improved electrical power generation for a given rotor speed. However, the core material has a saturation point beyond which additional increases in flux density produce minimal additional induction and can lead to nonlinear behavior, reduced permeability, and magnetic saturation, which significantly diminishes generator efficiency. Engineers must carefully design flux density to maximize power output without exceeding material limits, ensuring optimal performance over a wide range of wind conditions.

- Optimal Flux Density for Efficiency: Achieving optimal magnetic flux density in a Wind Power Generator Motor Stator Core is essential for maximizing generator efficiency. The ideal flux density ensures sufficient electromagnetic induction to generate high voltage and power output without inducing core saturation or excessive heat generation. For typical silicon steel stator cores, optimal operating flux densities generally range between 1.4 and 1.8 Tesla, although the exact value depends on the generator size, rotor speed, winding configuration, and cooling capability. Maintaining flux density within this optimal range enables the generator to operate efficiently under both rated and partial-load conditions, providing consistent performance across variable wind speeds. Engineering decisions around flux density directly impact material utilization, thermal behavior, and long-term operational reliability, making it a critical design parameter in wind turbine generator development.

-

Thermal Effects and Reliability: Magnetic flux density directly influences the thermal behavior of the stator core, which in turn affects reliability and lifespan. Higher flux density increases core losses, producing more heat that raises the temperature of both the core and the stator windings. Elevated temperatures can degrade insulation, reduce magnetic permeability, and accelerate aging of the core material, ultimately decreasing efficiency and shortening operational life. By optimizing flux density, heat generation is controlled, ensuring that the generator operates within safe temperature limits. This is particularly important for wind turbines, where variable wind speeds and fluctuating loads can create transient high flux densities. Maintaining flux density within design limits prevents thermal overstress, ensures consistent electromagnetic performance, and enhances reliability in both onshore and offshore wind applications, where maintenance access can be challenging and expensive.

-

Impact on Generator Performance under Variable Load: Magnetic flux density significantly affects the generator’s ability to maintain efficient operation across variable load conditions, which are inherent in wind energy systems due to fluctuating wind speeds. At low or partial loads, insufficient flux density can result in underwhelming voltage output, reducing overall efficiency and requiring additional reactive power compensation to stabilize the system. Conversely, excessive flux density at partial load can increase core losses without corresponding gains in output power, reducing net efficiency. Optimal flux density design ensures that the generator delivers stable voltage and power over the entire operating range, providing consistent energy conversion even under variable wind conditions.

-

Design Considerations: Achieving the appropriate magnetic flux density requires careful integration of core geometry, lamination thickness, core material selection, and winding configuration. Core material must exhibit high permeability and low hysteresis and eddy current losses at the target flux density. Lamination thickness and stacking techniques must minimize eddy currents without compromising mechanical stability. Winding arrangements and slot design must efficiently couple with the magnetic field to fully utilize the available flux. Engineers must balance these factors to optimize flux density while avoiding saturation, excessive heating, and vibration. Careful design ensures that the generator operates efficiently, reliably, and with minimal maintenance requirements, making flux density a key parameter in the electromagnetic, thermal, and economic performance of wind power generator stator cores.

简体中文

简体中文 English

English русский

русский Español

Español