How can variations in the slot geometry and tooth design of a Motor Stator Core optimize torque density and reduce magnetic saturation?

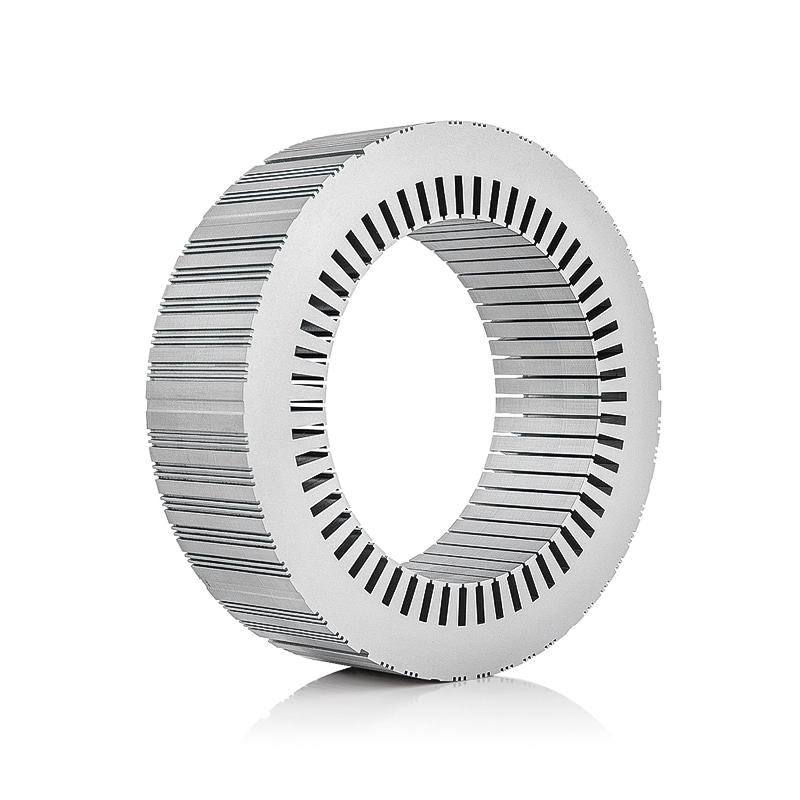

1. Influence of Slot Geometry on Magnetic Flux Distribution

The slot geometry of Motor Stator Core is one of the most influential design parameters determining how magnetic flux travels through the stator structure. The slots serve as the housing for copper windings, and their shape directly impacts how efficiently electromagnetic fields are produced and distributed. By modifying parameters such as slot width, depth, and shape (rectangular, trapezoidal, or semi-closed), engineers can control the distribution of magnetic flux and minimize local field distortion. A narrow slot enhances flux concentration but risks magnetic saturation near the tooth root, whereas a wide slot may lead to leakage flux and reduced torque production. To achieve an optimal configuration, electromagnetic simulation tools like Finite Element Analysis (FEA) are used to visualize flux lines and magnetic density variations. The objective is to achieve a uniform flux path across all stator teeth, minimizing localized saturation and maintaining maximum torque output. Advanced slot geometries—such as skewed or semi-closed slots—can further balance the electromagnetic field, reducing losses and improving the efficiency of torque generation.

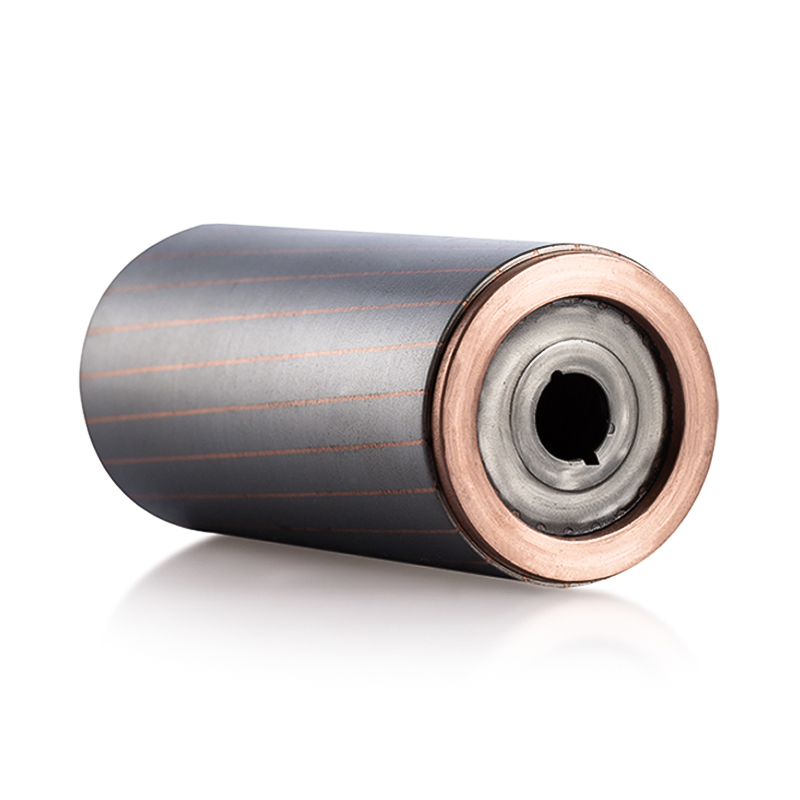

2. Effect of Tooth Shape on Torque Production and Saturation Reduction

The tooth design of the Motor Stator Core has a profound impact on how effectively magnetic energy is converted into mechanical torque. Each tooth acts as a conduit for magnetic flux between the stator and rotor, and its geometry determines how the flux lines concentrate and flow. Parameters like the tooth tip width, height, and chamfer radius directly affect torque density. For instance, an overly sharp tooth tip can lead to magnetic field crowding, causing localized saturation and heat generation. Conversely, a rounded or chamfered tooth tip distributes the magnetic field more evenly, improving magnetic efficiency and preventing premature material saturation. Designers often employ variable-tooth geometries, where the tip area is optimized to maximize air-gap flux while the root area maintains structural strength. This ensures a balance between magnetic performance and mechanical robustness. In applications requiring high torque density, such as electric vehicles or industrial drives, optimized tooth geometry can enhance energy conversion efficiency by up to 10–15%, while simultaneously lowering magnetic losses.

3. Optimization of Slot Opening and Slot Fill Factor

The slot opening—the narrow gap between adjacent tooth tips—affects both electromagnetic and mechanical characteristics. A smaller slot opening minimizes flux leakage but can increase cogging torque, while a wider opening allows better winding insertion at the cost of reduced electromagnetic coupling. Engineers must therefore achieve an equilibrium between manufacturability, magnetic performance, and torque smoothness. The slot fill factor, which defines how much copper is packed into the slot, also directly influences torque density. A higher fill factor means more current-carrying capacity, thus greater torque output. However, this must be balanced against thermal management, as denser windings generate more heat. Properly designed slot geometry ensures optimal copper utilization, enhanced cooling, and reduced energy losses. Computational thermal-electromagnetic coupling simulations are often used to validate slot geometry, ensuring that electrical loading does not exceed the stator’s magnetic saturation limit.

4. Reduction of Cogging Torque and Electromagnetic Vibration

Cogging torque is an unwanted pulsating torque generated due to the alignment between stator teeth and rotor magnets. Variations in slot geometry and tooth pitch are essential tools for mitigating this issue. The use of fractional-slot designs, skewed slots, or asymmetric tooth arrangements breaks the magnetic periodicity, reducing torque ripple and vibration. These design optimizations not only enhance torque smoothness but also lower acoustic noise levels. In high-speed motors or precision applications, even minor geometric changes in the stator core can significantly improve dynamic performance and minimize vibration-induced wear. The Motor Stator Core acts as the electromagnetic backbone of the motor; thus, its slot and tooth configuration must maintain harmonic balance while supporting smooth torque transitions. Reducing cogging torque also contributes to improved efficiency since less mechanical energy is wasted in overcoming irregular magnetic forces.

5. Balancing Magnetic Flux Density Across the Tooth Cross-Section

Achieving uniform magnetic flux distribution within the stator teeth is critical for preventing magnetic saturation. Variations in tooth design, such as tapering or flaring, can redistribute flux density from the high-stress root region to the tip, reducing flux concentration and enabling more consistent torque generation. Engineers often employ advanced FEA modeling to analyze magnetic density contours across each tooth and identify hotspots. Once detected, geometric adjustments—such as increasing the tooth base width or altering the slot depth—can be made to normalize the flux path. This uniformity not only enhances electromagnetic efficiency but also reduces hysteresis and eddy current losses. The result is a more energy-efficient Motor Stator Core that maintains stable performance across variable load conditions and speeds, preventing long-term degradation due to thermal hotspots or saturation-induced losses.

简体中文

简体中文 English

English русский

русский Español

Español