How does the Servo Motor Stator and Rotor Core contribute to reducing cogging and providing smooth operation during low-speed scenarios?

Minimizing Magnetic Pull Variations

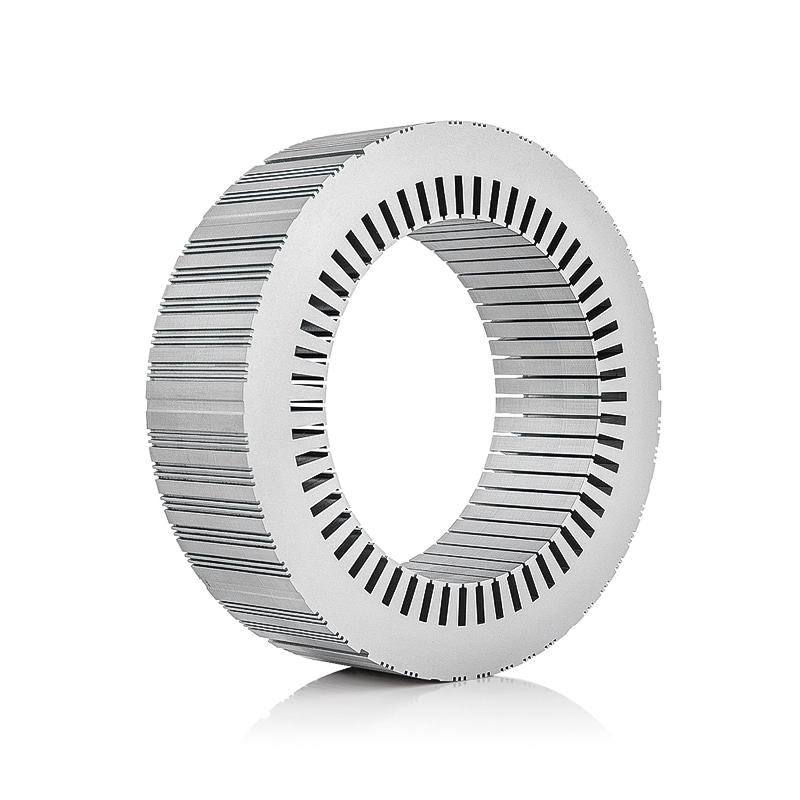

Cogging, a phenomenon characterized by jerky movement or torque variations at low speeds, is primarily caused by the interaction between the rotor and the stator’s magnetic poles. The Servo Motor Stator and Rotor Core play a vital role in minimizing these variations, contributing to smoother low-speed performance.

-

Slot and Pole Number Optimization: The number of slots in the stator and poles in the rotor significantly influences cogging. By optimizing the ratio between these components, the motor can achieve a smoother torque output. Typically, the design avoids integer ratios between rotor poles and stator slots, which helps in reducing the interaction between the rotor's magnetic poles and the stator's slots, thus mitigating cogging.

-

Skewing of Stator Laminations: Skewing refers to slightly rotating the stator core’s laminations relative to each other. This offset breaks up the alignment between rotor and stator slots, preventing the rotor from snapping into position with every slot. This reduces cogging by distributing the torque more evenly. Skewing is particularly effective at low speeds, where the effects of cogging are most noticeable, ensuring a smoother and quieter operation.

Using High-Quality Laminated Cores

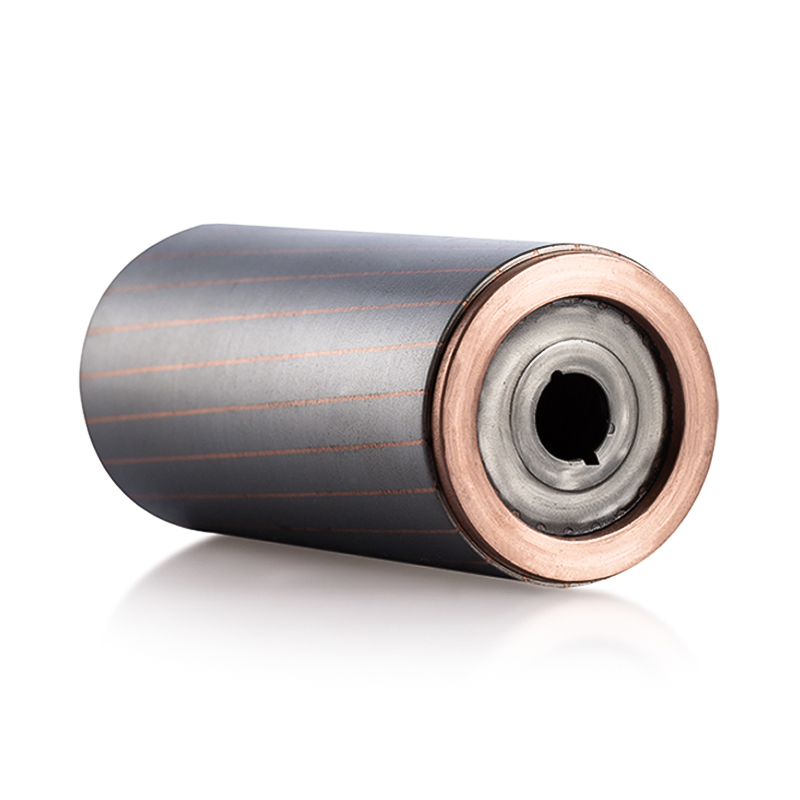

The Servo Motor Stator and Rotor Core are typically made of laminated steel, which provides several benefits that help reduce cogging and improve overall motor performance.

-

Reduced Eddy Current Losses: Laminated cores are constructed using thin, insulated steel sheets stacked together. This design minimizes eddy current losses that occur when current circulates in the motor’s core. At high frequencies, eddy currents can generate unwanted heat and cause inefficiencies. The laminated core reduces these losses, ensuring a more efficient transfer of energy, contributing to smoother motor operation and better low-speed performance.

-

Improved Magnetic Flux Control: Laminations in the stator and rotor help improve the consistency of the magnetic field within the motor, reducing fluctuations and irregularities. This ensures that the magnetic flux passing through the core remains stable, reducing any jittery or erratic behavior of the motor, especially when operating at low speeds.

Advanced Rotor Design

The rotor design is a critical factor in ensuring that the Servo Motor Stator and Rotor Core work together efficiently to reduce cogging. A well-designed rotor improves both performance and smoothness at low speeds by optimizing the interaction between the rotor’s magnetic field and the stator’s winding.

-

Permanent Magnet Optimization: In Permanent Magnet (PM) Servo Motors, the arrangement and quality of magnets in the rotor are critical for reducing cogging. Using high-quality, rare-earth magnets like Neodymium or Samarium Cobalt helps produce a stronger and more uniform magnetic field, which interacts more evenly with the stator. The precise placement of these magnets reduces the tendency for uneven torque generation, leading to less cogging and smoother performance, particularly in low-speed applications.

-

Segmented or Salient Pole Rotors: Some Servo Motor Stator and Rotor Cores employ a segmented or salient pole rotor design. In this setup, the rotor poles are magnetized in a non-uniform manner (with segmented or protruding poles), which helps distribute the magnetic interaction between the rotor and stator more evenly. This reduces cogging, as the rotor is less likely to snap into a fixed position, ensuring a smoother torque curve and eliminating sudden jerks or speed variations.

Reducing Harmonic Distortions

Harmonic distortions in the motor’s magnetic field contribute to the creation of cogging torque, especially at low speeds. The design of the Servo Motor Stator and Rotor Core plays a critical role in reducing these harmonic distortions.

-

Harmonic Field Distribution: The rotor and stator are engineered to ensure that the magnetic field produced during operation is as uniform as possible. This is achieved by minimizing the generation of higher-order harmonics, which would otherwise result in fluctuating magnetic forces and, consequently, torque ripples. By carefully controlling the design of the core, the motor’s torque becomes more consistent, resulting in smoother operation, especially during low-speed or fine-tuned movements.

-

Use of High-Fidelity Magnetics: The materials used in the core, such as high-permeability electrical steel, ensure that the magnetic flux is well-conducted through the stator and rotor. These materials reduce the effects of harmonic distortion, allowing for smooth torque delivery even at low rotational speeds.

Smooth Torque Delivery at Low Speeds

One of the core advantages of reducing cogging is achieving smooth torque delivery, particularly in low-speed operation, where even minor torque variations can lead to performance inconsistencies.

-

Torque Ripple Reduction: Torque ripple refers to variations in the output torque as the rotor rotates. This effect is more pronounced at low speeds and can cause unwanted vibrations or jerky motion. The improved design of the Servo Motor Stator and Rotor Core reduces torque ripple by minimizing magnetic flux disturbances and optimizing rotor-stator interaction. This results in a smoother and more consistent torque delivery, ensuring precise control during slow or low-speed movements.

-

Precise Speed Control: In applications that demand fine speed control, such as robotics or CNC machinery, Servo Motor Stator and Rotor Cores that minimize cogging enable the motor to maintain accurate speeds without fluctuations. This is vital when high precision is required, as even small variations in speed can lead to positional inaccuracies or deviations in performance.

简体中文

简体中文 English

English русский

русский Español

Español