Automotive Motor Stator and Rotor Cores: Design, Materials, and Key Performance

Introduction of automotive motor stator and rotor cores

The increasing popularity of electric vehicles and hybrid electric vehicles has brought about significant advancements in automotive technology. At the heart of these vehicles lie the automotive motor stator and rotor cores, which are integral components in electric motors. These cores play a crucial role in converting electrical energy into mechanical energy, ultimately enabling the movement of the vehicle. The growing demand for high-performance EVs and HEVs has led to a heightened focus on the efficiency and durability of automotive motor stator and rotor cores, with new materials and design innovations continuously being explored.

What Are Stator and Rotor Cores?

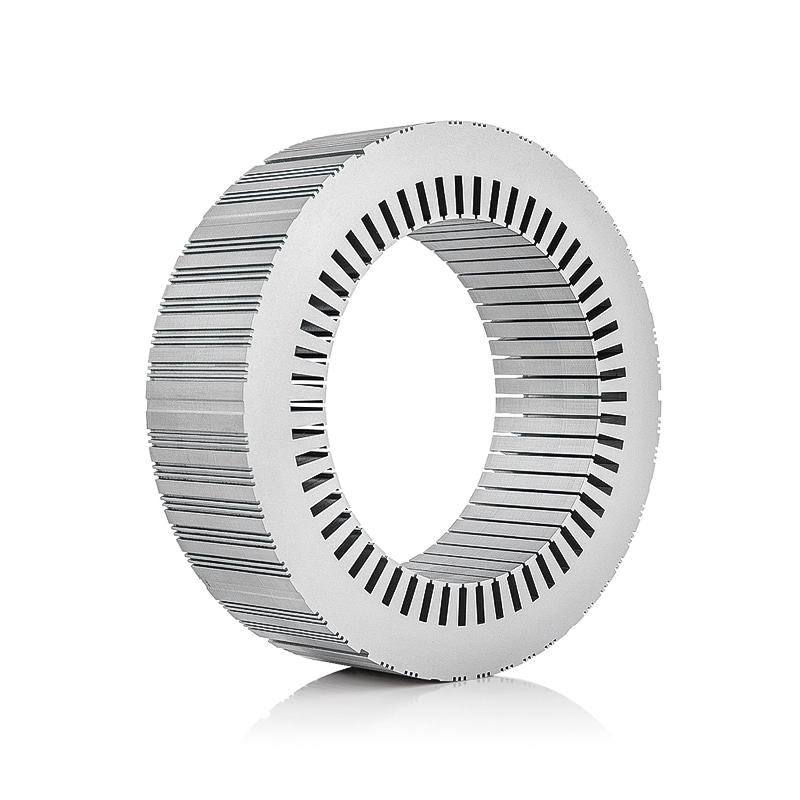

What is the Function of the Stator Core in an Automotive Motor?

The stator core in an automotive motor is the stationary part that produces a rotating magnetic field when energized. This rotating field interacts with the rotor core, generating torque to drive the vehicle. The stator core is usually made of electrical steel or soft magnetic composites to minimize energy losses and improve performance in automotive motors.

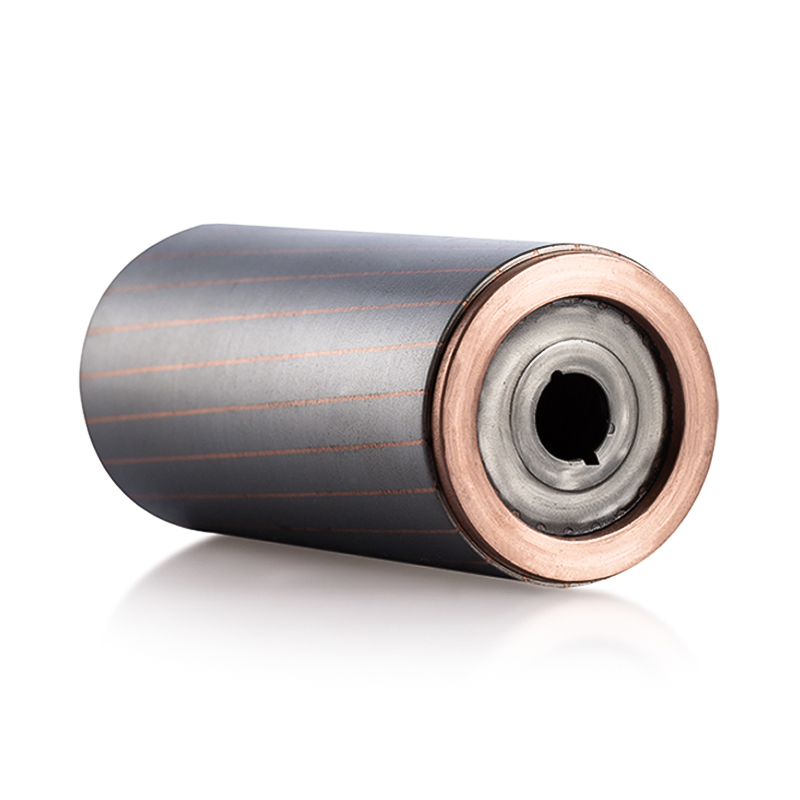

What Role Does the Rotor Core Play in the Motor’s Operation?

The rotor core is the rotating part of the motor, located inside the stator core. It is driven by the rotating magnetic field generated by the stator. The rotor core is typically constructed from laminated electrical steel or other high-performance materials to reduce energy losses and enhance motor efficiency. Together with the stator core, the rotor core enables the conversion of electrical energy into mechanical motion.

How Do Stator and Rotor Cores Work Together to Generate Torque?

The stator core and rotor core work in tandem to produce torque. When electric current flows through the stator windings, it creates a rotating magnetic field that induces current in the rotor core. This interaction between the magnetic fields of the stator and rotor generates torque, enabling the motor to produce mechanical power.

What Materials Are Used in Stator and Rotor Cores?

What are the Key Properties of Electrical Steel Used in Motor Cores?

Electrical steel, particularly silicon steel, is the most common material used for manufacturing automotive motor stator and rotor cores. It has excellent magnetic properties that help minimize losses. There are different grades of electrical steel:

-

Non-oriented electrical steel: Used for motors that require multi-directional magnetic properties.

-

Oriented electrical steel: Typically used in applications where the magnetic field is predominantly unidirectional, improving efficiency in motors like those used in EVs and HEVs.

What are the Advantages of Soft Magnetic Composites?

Soft Magnetic Composites are an alternative to electrical steel and are gaining attention in automotive motor designs. SMCs consist of iron powder combined with an insulating binder, which reduces eddy current losses and allows for more flexible core geometries. While SMCs offer performance advantages, they tend to be more expensive and less widely used than traditional electrical steels.

What Are the Emerging Materials for Motor Cores?

New materials such as amorphous alloys and nanocrystalline materials are being explored for use in automotive motor stator and rotor cores. These materials offer lower core losses, higher magnetic saturation, and improved efficiency. However, challenges with cost and scalability still limit their widespread adoption in the automotive industry.

What Design Considerations Are Important for Automotive Applications?

How Does Core Geometry Impact Motor Performance?

The geometry of the stator and rotor cores plays a significant role in the overall performance of the motor. Key design elements, such as slot design and pole configuration, impact the motor’s efficiency and torque output. A well-optimized core geometry can reduce losses and enhance motor performance in electric vehicle motors and hybrid vehicle motors.

What Are the Major Losses in Stator and Rotor Cores?

Core losses, including hysteresis losses and eddy current losses, can significantly reduce the efficiency of the motor. Hysteresis losses occur as the core material is magnetized and demagnetized, while eddy current losses arise from circulating currents induced in the core. The selection of materials like oriented electrical steel or soft magnetic composites helps minimize these losses and improve motor efficiency.

Why is Mechanical Strength and Durability Crucial for Automotive Motors?

For automotive motor stator and rotor cores, it’s essential to consider mechanical strength and durability to withstand vibrations, temperature variations, and other environmental factors. Materials with high vibration resistance and thermal stability are crucial for ensuring long-term performance and reliability in automotive applications.

What Manufacturing Processes Are Used for Motor Cores?

What is the Stamping and Lamination Process?

The stamping and lamination process is widely used to manufacture automotive motor stator and rotor cores. It involves cutting thin sheets of electrical steel into specific shapes and stacking them together to form the core. This process helps reduce eddy current losses by creating thin laminations. However, it can limit the flexibility of design.

What are the Different Winding Techniques for Automotive Motors?

Winding techniques, such as hairpin winding and distributed winding, are used to construct the stator windings in automotive motor stator and rotor cores. Hairpin winding involves the use of U-shaped wire segments that increase winding density and reduce copper losses, while distributed winding is used to minimize cogging torque and improve motor smoothness.

How Are Stator and Rotor Cores Assembled?

Once the stator and rotor cores are manufactured, they are assembled using methods like stacking or bonding. The stacking process aligns and stacks laminated sheets to form the core, while bonding involves gluing the laminations together. These assembly techniques ensure optimal magnetic performance and durability of the cores.

What are Stator and Rotor Cores?

What is the Function of the Stator Core in an Automotive Motor?

The stator core is a critical component in an automotive motor stator and rotor core system. It is the stationary part of the motor that surrounds the rotor. The primary function of the stator core is to generate a rotating magnetic field when electrical current flows through the stator windings. This magnetic field interacts with the rotor core, inducing motion and enabling the motor to produce torque.

The stator core is typically made from materials like electrical steel, such as silicon steel, or soft magnetic composites, due to their excellent magnetic properties. These materials are selected to minimize eddy current losses and hysteresis losses, which are crucial for maintaining the motor’s overall efficiency. The rotating magnetic field produced by the stator is responsible for driving the rotor and ultimately powering the vehicle.

What Role Does the Rotor Core Play in the Motor’s Operation?

The rotor core is the rotating component of the motor, located inside the stator core. It interacts with the magnetic field produced by the stator to generate torque. When the stator’s rotating magnetic field induces a current in the rotor windings, it creates its own magnetic field, which reacts with the stator’s magnetic field, causing the rotor to spin.

Like the stator core, the rotor core is often constructed from laminated electrical steel to minimize energy losses. Depending on the motor design, the rotor core can be made of various materials such as silicon steel, non-oriented electrical steel, or even soft magnetic composites in some advanced designs. The rotor’s rotation is crucial for converting electrical energy into mechanical energy, which drives the vehicle's wheels or auxiliary systems.

How Do Stator and Rotor Cores Work Together to Generate Torque?

The interaction between the stator core and rotor core is what enables the motor to generate torque. When current flows through the windings of the stator, it creates a rotating magnetic field. This magnetic field passes through the rotor, inducing a current within the rotor core. The induced current in the rotor creates its own magnetic field, which interacts with the magnetic field from the stator.

This interaction between the two magnetic fields creates a force that causes the rotor to rotate. The rotational motion of the rotor is then transferred to the motor’s shaft, producing the torque necessary to drive the vehicle. The automotive motor stator and rotor cores are designed to work in perfect synchronization to ensure that the motor operates efficiently, with minimal losses and maximum torque production.

The design of the stator and rotor cores, including the materials used and the geometry of the windings, plays a significant role in determining the efficiency and power density of the motor. Engineers continuously optimize these elements to meet the performance requirements of modern electric vehicles and hybrid vehicle motors.

What Materials Are Used in Stator and Rotor Cores?

What are the Key Properties of Electrical Steel Used in Motor Cores?

Electrical steel, particularly silicon steel (Si steel), is one of the most common materials used for manufacturing automotive motor stator and rotor cores. Electrical steel is chosen for its excellent magnetic properties, which help minimize energy losses during motor operation. It plays a crucial role in improving the efficiency of automotive motors by ensuring the core material can withstand high magnetic flux densities without significant energy dissipation.

There are various grades of electrical steel, which are designed to meet the specific requirements of different motor applications:

- Silicon steel: This is the most widely used form of electrical steel. It contains a small amount of silicon, which enhances the magnetic properties of the material, making it ideal for high-efficiency applications in automotive motors.

- Non-oriented electrical steel: NOES is used in motors that require multi-directional magnetic properties. It is beneficial in applications where the magnetic flux direction changes frequently, such as in electric and hybrid vehicle motors.

- Oriented electrical steel: OES is typically used in applications where the magnetic field is predominantly unidirectional. It offers superior magnetic properties in one direction, making it more efficient for use in motors with a fixed magnetic flux direction, such as in high-performance electric vehicles and hybrid electric vehicles.

What are the Advantages of Soft Magnetic Composites?

Soft Magnetic Composites are gaining attention as an alternative to traditional electrical steel in automotive motor stator and rotor cores. SMCs are made by combining iron powder with an insulating binder. This structure helps reduce eddy current losses and offers more flexible core geometries. This flexibility makes SMCs a promising material for automotive motors that require compact designs with high power density.

However, there are some trade-offs when using SMC compared to electrical steel:

- Advantages: SMCs allow for the design of complex geometries that can optimize motor performance, especially in applications requiring high-frequency operation. Their ability to reduce eddy current losses contributes to higher efficiency.

- Disadvantages: SMCs tend to be more expensive than traditional electrical steels, and their performance in high-power applications may be limited. Additionally, SMCs have lower magnetic saturation levels compared to electrical steel, which can reduce their overall effectiveness in certain high-performance motors.

What Are the Emerging Materials for Motor Cores?

As automotive motor technology advances, engineers are exploring new materials to further enhance the performance and efficiency of stator and rotor cores. Two promising materials are amorphous alloys and nanocrystalline materials.

- Amorphous alloys: Amorphous alloys are metallic materials that lack a crystalline structure. These materials have excellent magnetic properties and offer very low core losses. The lack of crystal grain boundaries allows for better performance in high-frequency applications, which is particularly useful in modern electric and hybrid vehicle motors. However, amorphous alloys are relatively expensive and challenging to produce at a large scale.

- Nanocrystalline materials: Nanocrystalline materials are made up of fine-grained particles, which provide improved magnetic performance and lower core losses compared to conventional electrical steels. These materials are still in the development phase but have the potential to offer higher efficiency and better thermal stability for automotive motor stator and rotor cores. Like amorphous alloys, their cost and scalability remain challenges for widespread adoption.

Comparison of Materials Used in Stator and Rotor Cores

| Material | Properties | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| Silicon Steel (Si Steel) | High magnetic permeability, good mechanical properties | Widely available, cost-effective, good performance for most applications | Higher eddy current losses at high frequencies | General automotive motor applications |

| Non-oriented Electrical Steel (NOES) | Multi-directional magnetic properties | Good for motors with changing magnetic flux direction | Lower efficiency in high-performance applications | Electric and hybrid vehicle motors |

| Oriented Electrical Steel (OES) | Unidirectional magnetic properties | High efficiency in fixed magnetic flux applications | More expensive than non-oriented steel | High-performance electric and hybrid vehicle motors |

| Soft Magnetic Composites (SMC) | Iron powder combined with an insulating binder | Reduced eddy current losses, flexible design | More expensive, lower magnetic saturation | Compact high-density automotive motor applications |

| Amorphous Alloys | Non-crystalline structure, very low core losses | Very low core losses, improved high-frequency performance | Expensive, difficult to scale production | Advanced automotive motor applications |

| Nanocrystalline Materials | Fine-grained structure, low core losses | Improved magnetic performance, higher efficiency | High cost, scalability issues | Emerging high-efficiency automotive motors |

What Design Considerations Are Important for Automotive Applications?

How Does Core Geometry Impact Motor Performance?

The geometry of the stator and rotor cores is one of the most significant factors influencing the overall performance of automotive motors. The design of the stator and rotor cores—particularly the slot design and pole configuration—directly impacts the motor's efficiency, torque output, and overall power density. These geometrical elements determine how effectively the motor can generate torque while minimizing energy losses, making them crucial for the performance of electric vehicles and hybrid electric vehicles, where performance and efficiency are top priorities.

One important design factor is the slot design. The number, size, and shape of the slots in the stator affect the magnetic flux distribution and the winding configuration. Optimizing the slot design ensures efficient flux path and reduces losses in the motor. A well-designed slot system can improve torque generation, minimize cogging, and reduce noise, all while enhancing the motor's overall efficiency.

The pole configuration is also a critical factor in core geometry. The number and arrangement of poles in the stator influence the speed and torque characteristics of the motor. For example, motors with more poles generally produce higher torque at lower speeds, making them ideal for applications in vehicles that require high power density. By adjusting the pole configuration, engineers can design motors that offer optimized torque, power, and efficiency across a wide range of driving conditions.

Ultimately, the goal of optimizing core geometry is to strike a balance between performance factors such as torque, efficiency, and power density, while minimizing core losses and maintaining a compact design. In modern EVs and HEVs, this balance is essential to meet the demands of consumers for higher performance and longer range without compromising space and weight.

What Are the Major Losses in Stator and Rotor Cores?

Motor efficiency is heavily influenced by the losses that occur in the stator and rotor cores. The two primary losses in automotive motors are hysteresis losses and eddy current losses. Minimizing these losses is crucial to enhancing the motor’s overall efficiency and performance.

- Hysteresis Losses: Hysteresis losses occur as the magnetic material in the stator and rotor cores is magnetized and demagnetized with each cycle of operation. Every time the direction of the magnetic field changes, the magnetic domains within the core material realign, resulting in energy loss in the form of heat. This energy dissipation can significantly reduce the motor’s efficiency. To reduce hysteresis losses, it is essential to use core materials with low coercivity and high magnetic permeability, such as oriented electrical steel (OES). These materials are designed to minimize the energy required to reverse the magnetic field, improving the overall efficiency of the motor.

- Eddy Current Losses: Eddy current losses are caused by circulating currents induced within the core material as it interacts with the alternating magnetic field. These circulating currents produce heat, which wastes energy. To mitigate eddy current losses, core materials are typically laminated. The lamination process involves stacking thin sheets of electrical steel that are electrically insulated from one another. This reduces the path available for the eddy currents to flow, thus limiting their size and energy dissipation. Advanced materials like soft magnetic composites (SMC) also help to reduce eddy current losses, especially in high-frequency applications, by providing a more effective insulation layer between the grains of iron powder, further minimizing energy losses.

Reducing both hysteresis and eddy current losses is key to improving motor efficiency, especially in applications where power density and overall system efficiency are critical, such as in electric and hybrid vehicles. Therefore, selecting the right materials and design techniques for the stator and rotor cores is essential for optimizing motor performance and minimizing energy waste.

Why is Mechanical Strength and Durability Crucial for Automotive Motors?

The mechanical strength and durability of automotive motor stator and rotor cores are critical to ensuring the longevity and reliability of the motor. Automotive motors, especially those used in electric and hybrid vehicles, operate under demanding conditions, including high temperatures, mechanical stress, and constant vibration. Therefore, the materials used for the stator and rotor cores must be able to withstand these stresses without degrading over time.

- Vibration Resistance: Motors in electric vehicles are exposed to a variety of mechanical forces, including vibrations caused by road conditions, acceleration, deceleration, and motor operation. If the motor's stator and rotor cores cannot resist these vibrations, they may experience fatigue, which can lead to failures such as winding insulation breakdown or structural damage to the core itself. To prevent this, materials with high vibration resistance, such as laminated electrical steel or soft magnetic composites, are selected for their ability to withstand these mechanical stresses. The core's design also plays a role in vibration resistance, with techniques such as bonding or stacking laminations to improve mechanical strength and durability.

- Thermal Stability: High temperatures generated by the motor during operation can cause degradation of materials and reduce the efficiency of the motor. The stator and rotor cores must exhibit high thermal stability to ensure consistent performance in extreme temperature conditions. Automotive motors in EVs and HEVs often operate in environments that experience significant temperature fluctuations, from hot summer days to cold winter nights. Materials like silicon steel and soft magnetic composites are specifically chosen for their ability to maintain their magnetic properties and structural integrity at elevated temperatures. In addition, advanced cooling systems are often incorporated into the motor design to dissipate heat effectively and maintain the motor’s optimal operating temperature range.

- Corrosion Resistance: Motors in automotive applications are exposed to various environmental factors, such as moisture, salt, and chemicals from road surfaces, which can cause corrosion over time. Corrosion resistance is, therefore, an important consideration when selecting materials for the stator and rotor cores. Materials like silicon steel and soft magnetic composites are often treated with protective coatings to improve their corrosion resistance, thereby extending the lifespan of the motor and ensuring reliable operation even in harsh conditions.

By carefully selecting materials and designing stator and rotor cores that can withstand mechanical stresses, thermal extremes, and corrosive environments, automotive manufacturers ensure that their electric and hybrid vehicles provide reliable, long-lasting performance in the face of real-world challenges.

What Manufacturing Processes Are Used for Automotive Motor Stator and Rotor Cores?

What is the Stamping and Lamination Process?

The stamping and lamination process is widely used to manufacture automotive motor stator and rotor cores. This process involves cutting thin sheets of electrical steel into specific shapes using a stamping die and stacking them together to form the core. The individual sheets, or laminations, are electrically insulated from one another to minimize eddy current losses, which helps improve the motor's efficiency.

The stamping process allows for the mass production of stator and rotor cores with precise dimensions, ensuring consistency across multiple units. The lamination process helps to reduce core losses, particularly eddy current losses, which would otherwise waste energy and reduce motor efficiency. Stamped cores are typically made from electrical steel, such as silicon steel or soft magnetic composites, depending on the motor’s requirements.

However, while the stamping and lamination process is efficient and cost-effective, it has some limitations. The main challenge lies in the flexibility of design complex shapes or geometries may require advanced tooling or custom dies, which can increase production costs. Additionally, this process may not be suitable for high-frequency applications, where other manufacturing techniques like soft magnetic composites may offer better performance.

What Are the Winding Techniques Used in Automotive Motors?

The winding process is crucial for creating the stator windings, which are essential for generating the rotating magnetic field that drives the rotor core in automotive motors. There are several winding techniques used, with two of the most common being hairpin winding and distributed winding.

- Hairpin Winding: Hairpin winding involves using U-shaped wire segments that are bent into a hairpin shape and inserted into the stator slots. This technique allows for higher winding density, which reduces copper losses and increases motor efficiency. The increased winding density also contributes to higher torque and power output, making it ideal for automotive motors that require high performance. Additionally, hairpin winding improves the overall reliability and durability of the motor, as the winding remains securely in place within the stator core.

- Distributed Winding: Distributed winding involves distributing the windings evenly across multiple stator slots. This technique helps to minimize cogging torque, which can cause vibrations and noise in the motor. Distributed winding improves the smoothness of the motor’s operation, contributing to a quieter and more efficient motor. It also offers better cooling characteristics since the windings are more evenly distributed, reducing the chance of hot spots that could damage the insulation or windings.

Both hairpin and distributed winding techniques offer distinct advantages depending on the motor's specific requirements. Hairpin winding is often favored for its compactness and ability to handle higher currents, while distributed winding is preferred for its ability to reduce cogging and improve smoothness in operation.

How Are Stator and Rotor Cores Assembled?

Once the stator and rotor cores are manufactured, they are assembled using two main methods: stacking and bonding.

- Stacking: The stacking process involves aligning and stacking the laminated sheets of electrical steel to form the stator or rotor core. The sheets are carefully stacked to ensure that the layers align properly, creating an efficient flux path through the core. This method is commonly used in automotive motor stator and rotor cores due to its simplicity and effectiveness in ensuring proper magnetic performance. Stacking helps to minimize the eddy current losses associated with solid-core designs, as the lamination of the sheets creates multiple thin layers that prevent large circulating currents from forming.

- Bonding: In the bonding process, the individual laminations are glued together using adhesive materials that maintain their insulating properties. Bonding provides additional mechanical strength to the core structure and can help to improve vibration resistance and durability. It is often used in advanced motor designs where higher performance and precision are required. Bonding also reduces noise during motor operation, as the adhesive layer dampens vibrations between the laminations.

Both stacking and bonding techniques are essential in the manufacturing of automotive motor stator and rotor cores. Stacking is widely used for its efficiency and cost-effectiveness, while bonding provides additional advantages in terms of vibration resistance and noise reduction. In many cases, manufacturers will combine both methods to achieve the best balance between performance, durability, and cost.

What Are the Applications of Stator and Rotor Cores in Electric and Hybrid Vehicles?

What Are the Stator and Rotor Core Requirements for Traction Motors?

Traction motors are the primary source of propulsion in electric vehicles and hybrid electric vehicles. The stator and rotor cores in these motors must meet specific performance requirements to ensure efficient and reliable operation under various driving conditions. Traction motors need to generate high torque and power while maintaining low energy losses, especially in electric vehicles that rely solely on the motor for propulsion.

The stator core in traction motors typically utilizes high-performance materials like oriented electrical steel or silicon steel, which provide excellent magnetic properties, high efficiency, and low core losses. The rotor core is usually made from laminated electrical steel or soft magnetic composites to reduce eddy current and hysteresis losses. The laminated design helps improve the overall power density and efficiency of the motor.

For traction motors, the core geometry plays a critical role. Optimizing the number of poles, slot design, and pole configuration ensures that the motor can deliver high torque and speed, especially during acceleration. Additionally, the design needs to accommodate the mechanical stresses and thermal conditions in automotive applications. High thermal stability and vibration resistance are essential to maintaining motor performance over extended periods and across various environmental conditions.

How Are Stator and Rotor Cores Used in Auxiliary Motors?

In addition to traction motors, electric and hybrid vehicles also use auxiliary motors to drive smaller systems such as pumps, fans, air conditioning compressors, and power steering units. These motors are typically smaller than traction motors but still require high efficiency and reliability to meet the needs of the vehicle.

The stator and rotor cores in auxiliary motors are designed for smaller-scale applications, where compactness and efficiency are paramount. These motors often use similar core materials like electrical steel or soft magnetic composites, though the specific material choice may depend on the size and type of motor. For instance, SMCs are increasingly being used in smaller auxiliary motors for their ability to handle high-frequency operations and minimize core losses.

In auxiliary motors, core geometry is tailored for the specific application. For example, motors used for air conditioning compressors need to be optimized for compact size, power density, and low noise, while those used for pumps and fans require a more durable and efficient design to operate continuously under load. The small size and lightweight design of auxiliary motors make them crucial for the overall energy efficiency and reliability of EVs and HEVs.

What Is the Role of Stator and Rotor Cores in Regenerative Braking Systems?

Regenerative braking is a technology used in electric and hybrid vehicles to recover energy during braking and convert it back into electrical energy, which can then be stored in the vehicle's battery. The stator and rotor cores play a crucial role in this energy recovery process by enabling the motor to act as both a generator and a motor, depending on the vehicle’s speed and braking requirements.

When the vehicle brakes, the direction of the motor's rotation is reversed, and it starts functioning as a generator. The rotor is driven by the vehicle's kinetic energy, and the magnetic field in the stator core induces a current in the rotor windings. This current is then fed back into the vehicle's battery. The stator core must be designed to handle high-frequency, high-torque loads during braking, with minimal core losses to maximize energy recovery efficiency.

Materials used for the stator and rotor cores in regenerative braking systems are often selected for their ability to handle frequent cycling between motoring and generating modes. Electrical steel with low losses, such as oriented electrical steel , is commonly used in these applications to reduce core losses and increase overall system efficiency. Additionally, the core design must be optimized for high torque at low speeds, as regenerative braking typically occurs when the vehicle is decelerating or at low speed.

What Are the Key Performance Parameters for Automotive Motor Stator and Rotor Cores?

How Do Core Losses Impact Efficiency in Automotive Motor Stator and Rotor Cores?

Efficiency is one of the most critical parameters when designing automotive motor stator and rotor cores, as it directly influences the overall performance of electric and hybrid vehicles. Core losses, which include both hysteresis losses and eddy current losses, significantly impact the motor's efficiency.

Hysteresis losses occur when the magnetic material of the core repeatedly magnetizes and demagnetizes as the current changes direction. This process generates heat, reducing the energy efficiency of the automotive motor stator and rotor cores. Eddy current losses, on the other hand, arise from circulating currents induced within the core material, leading to additional energy dissipation. Both types of losses are undesirable, as they reduce the power output and overall efficiency of the motor.

To minimize core losses, high-quality materials such as silicon steel and oriented electrical steel are typically used in automotive motor stator and rotor cores. Additionally, innovative materials like soft magnetic composites and amorphous alloys offer lower core losses, enhancing efficiency in specific applications. A well-designed automotive motor stator and rotor core with optimized core geometry can further reduce core losses, improving the overall energy efficiency of the vehicle.

What Is Torque Density, and How Is It Optimized in Automotive Motor Stator and Rotor Cores?

Torque density refers to the amount of torque a motor can produce per unit of its volume or mass. For automotive motors, especially those used in EVs and HEVs, maximizing torque density is essential to achieve high performance while maintaining compact and lightweight motor designs.

To optimize torque density, engineers carefully select materials and design the stator and rotor cores to maximize magnetic flux while minimizing losses. Electrical steel, particularly silicon steel and non-oriented electrical steel, is commonly used in automotive motor stator and rotor cores due to its excellent magnetic properties, which help generate strong magnetic fields and enhance torque output.

Design optimization also involves adjusting core geometry, such as slot design and pole configuration, to ensure the most efficient use of available space in automotive motor stator and rotor cores. The goal is to achieve maximum torque production without compromising the motor's weight or size, which is particularly important in automotive applications where space is limited.

What Is Power Density, and How Is It Achieved in Automotive Motor Stator and Rotor Cores?

Power density is another key performance parameter, referring to the amount of power a motor can produce relative to its size or weight. For automotive motors, achieving high power density is crucial to ensure that the motor is both compact and capable of delivering the necessary power for vehicle propulsion.

Power density can be increased by selecting high-performance materials with excellent magnetic properties, such as oriented electrical steel and soft magnetic composites, which allow the motor to generate stronger magnetic fields and higher torque at smaller sizes. The optimization of core geometry, such as using thinner laminations and reducing the air gap between the stator and rotor, further contributes to improving power density in automotive motor stator and rotor cores.

In automotive applications, a compact motor design with high power density ensures that the motor can fit into constrained spaces, such as the engine compartment of a vehicle, while still providing sufficient power for efficient operation. Additionally, lightweight designs reduce the overall weight of the vehicle, contributing to improved performance, energy efficiency, and range for electric and hybrid vehicles.

Summary of Key Performance Parameters in Automotive Motor Stator and Rotor Cores

| Performance Parameter | Description | Impact on Automotive Motor Stator and Rotor Cores Design |

|---|---|---|

| Efficiency | Determined by core losses like hysteresis and eddy currents, affecting energy use and heat dissipation. | Reduced core losses improve efficiency, allowing for better range and performance in EVs and HEVs with optimized automotive motor stator and rotor cores. |

| Torque Density | The amount of torque produced per unit of volume or mass of the motor. | Higher torque density increases the automotive motor stator and rotor cores performance without increasing weight or size, improving vehicle acceleration. |

| Power Density | The amount of power generated relative to the motor's size or weight. | Increased power density allows for compact and lightweight automotive motor stator and rotor cores designs, essential for automotive applications. |

The performance of automotive motor stator and rotor cores is influenced by various parameters, including efficiency, torque density, and power density. As the automotive industry continues to evolve with the growth of electric vehicles and hybrid electric vehicles, these performance metrics have become essential for optimizing motor designs. Innovations in materials such as soft magnetic composites and oriented electrical steel, along with design considerations like core geometry and material selection, are enabling more efficient, compact, and powerful motor solutions.

By minimizing core losses and maximizing torque and power density, manufacturers can create motors that are not only highly efficient but also capable of meeting the increasing demands for power and performance in modern vehicles. Achieving these objectives requires a balanced approach to material choice, core design, and manufacturing processes. The continuous refinement of these factors will pave the way for next-generation automotive motor stator and rotor cores that push the boundaries of efficiency, power, and performance in the automotive industry.

简体中文

简体中文 English

English русский

русский Español

Español