How does the thickness and stacking factor of laminations in a Motor Stator Core impact energy efficiency, eddy current losses, and operational noise levels?

1. Role of Lamination Thickness in Controlling Eddy Current Losses

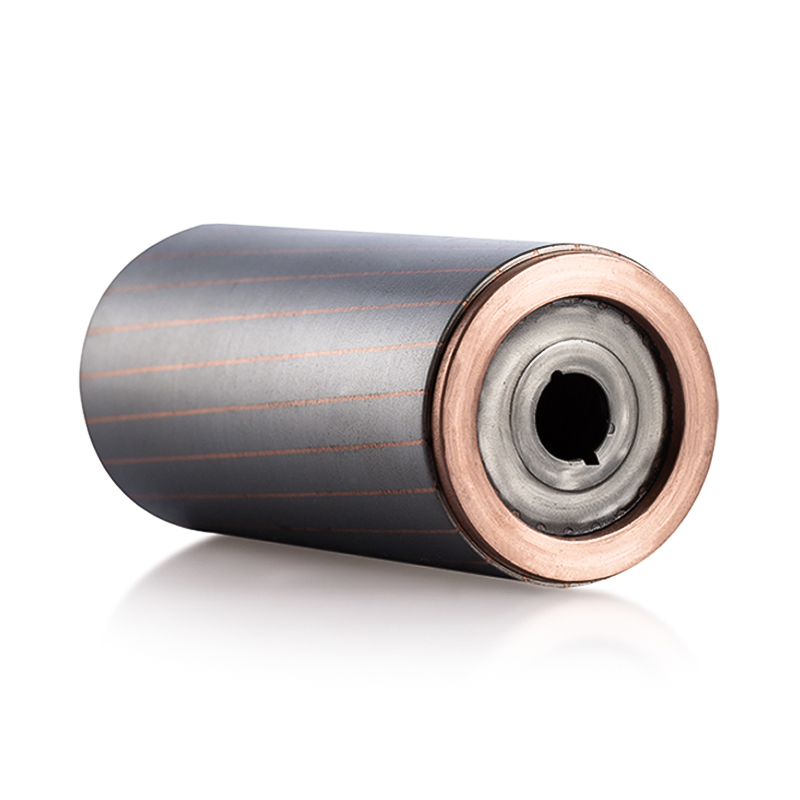

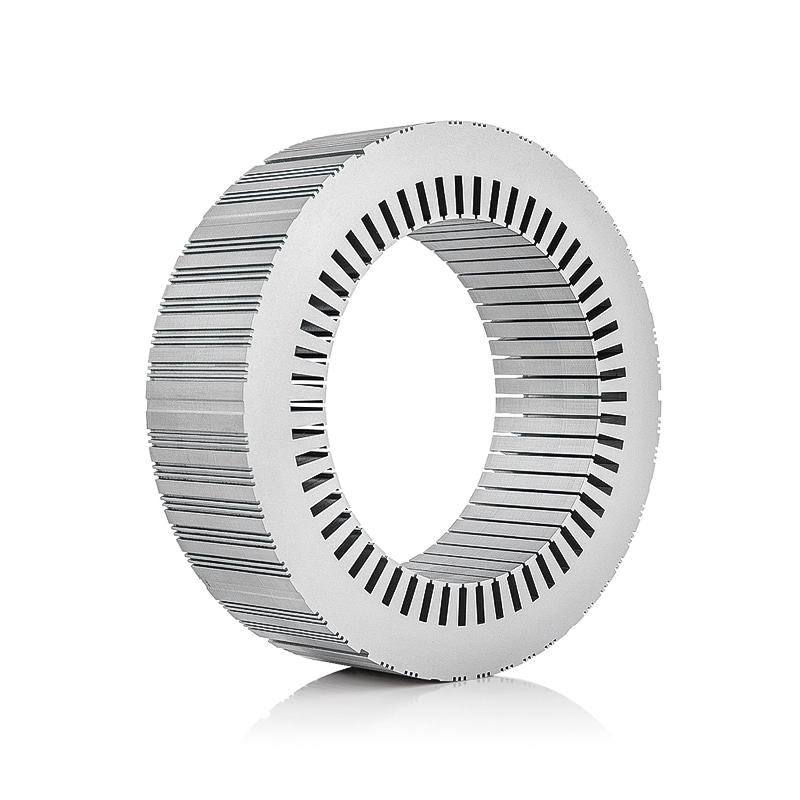

The thickness of laminations in Motor Stator Core directly determines the magnitude of eddy current losses generated within the magnetic material. Eddy currents are circular electrical currents induced in the stator core when it is exposed to alternating magnetic fields. Thicker laminations allow larger current loops to form, leading to higher resistive losses and unwanted heat generation. In contrast, thinner laminations restrict the loop area available for eddy currents, thereby significantly reducing energy dissipation through Joule heating. The correlation between lamination thickness and eddy current losses follows a quadratic relationship, meaning that halving the lamination thickness can reduce eddy current losses by approximately 75%. This is why modern high-efficiency motors often use laminations as thin as 0.2 to 0.35 mm, compared to older designs that used 0.5 mm or more. Advanced materials like high-silicon electrical steel or amorphous alloys can further suppress eddy currents because of their higher resistivity and optimized crystalline structure. Therefore, reducing lamination thickness not only improves electrical performance but also enhances the overall thermal efficiency and lifespan of the motor by limiting excessive core heating.

2. Influence of Lamination Thickness on Magnetic Performance and Energy Efficiency

Thinner laminations improve the magnetic performance of the Motor Stator Core by reducing core losses, which consist of both hysteresis and eddy current losses. By minimizing these losses, more of the input electrical energy is converted into useful mechanical torque, thus enhancing the motor’s energy efficiency. However, it is essential to balance lamination thinness with magnetic permeability. Excessively thin laminations may increase the number of insulation layers between sheets, slightly reducing the effective cross-sectional area for magnetic flux flow. This could lower the magnetic conductivity of the stator core, causing a marginal drop in torque density. To counteract this, engineers select materials with high magnetic permeability and use optimized stacking techniques to maintain continuity in the magnetic circuit. In practice, the ideal lamination thickness is determined through electromagnetic simulations that evaluate flux density, loss components, and motor efficiency across operational speeds. Proper thickness selection ensures that the stator core achieves minimal total loss while maintaining strong magnetic coupling and consistent performance under load variations.

3. Stacking Factor and Its Effect on Magnetic Path Continuity

The stacking factor is the ratio of the net iron cross-sectional area to the total area occupied by the stack of laminations, including the insulating layers between them. It reflects how tightly and effectively the laminations are assembled. A higher stacking factor indicates less air gap or insulation material between laminations, providing a better magnetic path for flux flow. Typical stacking factors range between 0.92 and 0.98, depending on material type and coating thickness. While a high stacking factor improves magnetic flux continuity and torque generation, it also slightly increases eddy current risk due to reduced insulation. Conversely, a low stacking factor minimizes eddy currents but introduces excessive air gaps, increasing magnetic reluctance and decreasing efficiency. Engineers must therefore optimize the stacking factor based on the motor’s operational frequency and application requirements. Modern manufacturing processes, such as laser-cutting precision stacking and automated lamination bonding, allow tight control over the stacking factor, ensuring consistent electromagnetic performance across production batches.

4. Relationship Between Lamination Quality and Hysteresis Loss

Apart from eddy current losses, the lamination thickness and material characteristics also influence hysteresis losses, which arise from the continuous magnetization and demagnetization of the stator core during operation. Hysteresis loss is primarily dependent on the material’s coercivity and operating frequency, but lamination integrity plays an indirect yet important role. Uniform and precisely cut laminations prevent localized stress and microstructural distortion, which could otherwise increase coercivity and magnetic resistance. Thicker laminations, when combined with poor stacking accuracy, can create uneven magnetic paths, resulting in localized magnetic hotspots and higher hysteresis losses. On the other hand, using thinner, stress-relieved laminations ensures smoother magnetic transitions and minimizes energy wasted in repeated magnetic cycling. Maintaining consistent lamination thickness and high stacking accuracy enhances the magnetic response, reduces hysteresis, and improves overall energy efficiency.

5. Impact of Lamination Stacking on Vibration and Noise Levels

Mechanical vibration and audible noise in electric motors often stem from magnetic imbalances and structural resonances within the Motor Stator Core. Improper stacking, uneven compression, or misalignment between laminations can create variations in the magnetic reluctance path, leading to localized magnetic attraction forces that fluctuate as the motor operates. These force fluctuations manifest as audible humming or whining noise, especially at higher frequencies. The well-optimized stacking process ensures that each lamination is evenly compressed, minimizing internal gaps and maintaining uniform magnetic flux distribution. Adhesive bonding, interlocking, or laser welding methods can be used to maintain mechanical integrity while preserving electromagnetic isolation between sheets. Thinner laminations reduce the amplitude of magnetostriction (the dimensional change of material due to magnetic field), leading to lower vibration and quieter operation.

简体中文

简体中文 English

English русский

русский Español

Español