How does the lamination thickness of an Industrial Fan Stator Core influence eddy current losses and operational efficiency?

1. Fundamentals of Eddy Currents in Stator Cores

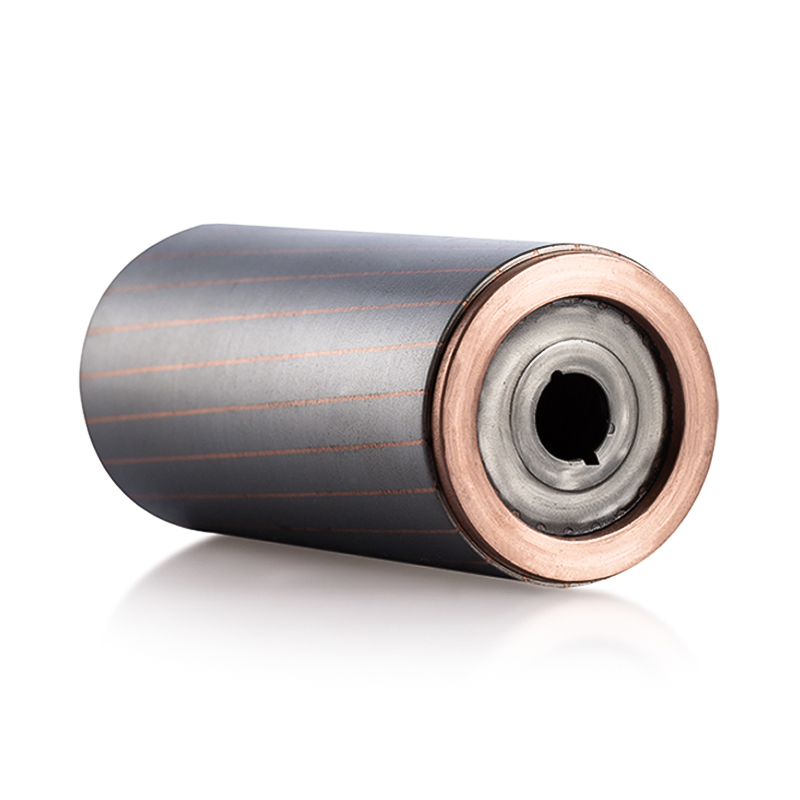

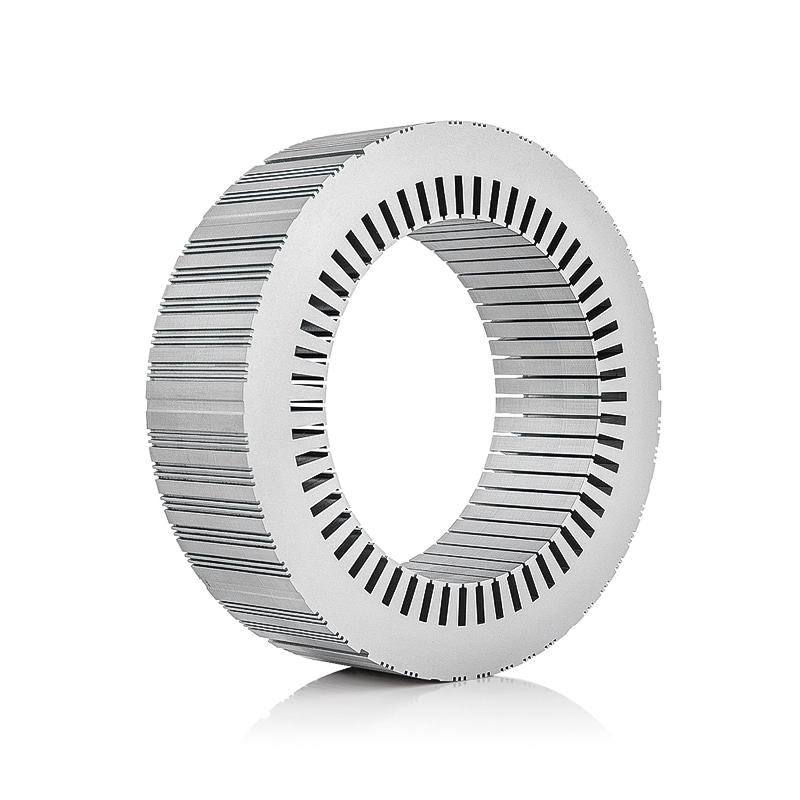

Eddy currents are localized circulating electrical currents induced in the conductive core of Industrial Fan Stator Core by the alternating magnetic fields generated during motor operation. These currents flow in closed loops within the lamination material and generate heat due to electrical resistance, which is effectively wasted energy. The thickness of each lamination directly affects the size of these loops. Thicker laminations provide a larger cross-sectional area for eddy currents to flow, resulting in higher resistive heating and increased energy losses. In contrast, thinner laminations restrict the path of eddy currents, reducing their intensity and thereby minimizing heat generation. Understanding this fundamental relationship is critical for engineers aiming to optimize motor efficiency and reliability.

2. Impact on Operational Efficiency and Energy Consumption

Eddy current losses directly decrease the overall efficiency of an industrial fan motor by converting a portion of electrical energy into heat instead of mechanical work. By using thinner laminations, the amplitude of eddy currents is reduced, thereby lowering resistive losses. This improvement translates into more efficient energy conversion, reduced electricity consumption, and lower operating costs over time. In high-power or continuous-duty industrial fans, even small reductions in eddy current losses can have a substantial impact on energy savings and operational cost-effectiveness. Conversely, cores with thicker laminations can generate excessive losses, particularly at high operating speeds, reducing both performance and efficiency.

3. Influence on Thermal Management and Core Temperature

Heat generated by eddy currents accumulates within the stator core, raising the temperature of the lamination stack and the surrounding insulation. Elevated core temperatures can accelerate the aging of insulation materials, leading to premature failure or reduced lifespan of the motor. Using thinner laminations helps mitigate these heat generation issues, as smaller eddy current loops produce less thermal energy. This results in lower peak core temperatures and reduced thermal stress on both the magnetic material and insulation layers. Effective thermal management reduces the need for intensive cooling systems and enhances long-term reliability, especially in industrial environments where fans operate continuously or under high load.

4. Balancing Electrical Performance with Mechanical Strength

While thinner laminations are beneficial for reducing eddy current losses, they must retain sufficient mechanical strength to withstand stresses from vibration, centrifugal forces, and assembly handling. Laminations that are too thin may deform, bend, or warp under operational loads, compromising the structural integrity of the stator core. Therefore, engineers must optimize lamination thickness to achieve a balance between magnetic efficiency and mechanical durability, ensuring that the stator remains robust while minimizing electrical losses. Material selection and lamination stacking techniques further influence the mechanical resilience of the core.

5. High-Frequency Operational Considerations

Industrial fans operating at higher electrical frequencies or variable-speed drives are particularly sensitive to eddy current losses, as these losses increase with the square of the frequency. Thinner laminations are critical in high-frequency applications because they restrict the size of circulating currents and help maintain efficiency. At lower operating frequencies, slightly thicker laminations may be acceptable, but the relationship between lamination thickness and frequency-dependent losses must be carefully considered during the design phase to ensure optimal performance. This balance allows industrial fan motors to operate efficiently across varying speeds and load conditions.

简体中文

简体中文 English

English русский

русский Español

Español