How does the rotor core influence the generator’s ability to operate at different speeds or under varying load conditions?

1. Magnetic Field Interaction and Induction Efficiency

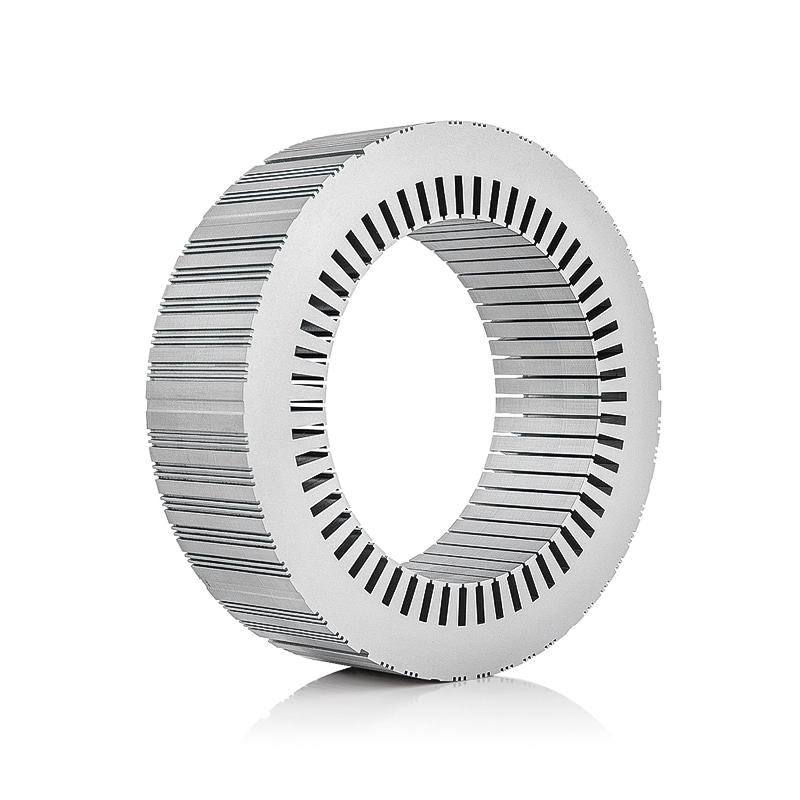

The rotor core is a critical component in the process of electromagnetic induction, where the magnetic flux generated by the stator induces a current in the rotor. The interaction between the rotor core and the magnetic field directly influences the generator's ability to operate efficiently at various speeds and load conditions. When a generator is operating, the rotor core must maintain optimal interaction with the magnetic field to induce a consistent voltage in the winding. As the rotor speed increases, the rate of change of the magnetic flux also increases, which influences the voltage and current output.

A highly efficient rotor core ensures that the generator is able to generate sufficient electromagnetic force across a range of speeds by optimizing the flux linkage between the stator and rotor. A core with low resistance to magnetic flow (i.e., low reluctance) ensures minimal energy losses, which helps the generator maintain high induction efficiency at both low and high speeds. In low-speed conditions, it is crucial that the rotor core maintains a strong magnetic field with minimal flux leakage. As the speed increases, the rotor core’s ability to efficiently transfer magnetic energy to the stator ensures that the generator performs optimally under varying speeds and loads.

2. Impact on Speed Regulation

Speed regulation is critical for ensuring that a generator consistently provides stable output despite fluctuations in load. The rotor core design directly affects the generator's ability to handle speed regulation across different load scenarios. The inductive reactance of the rotor core plays a crucial role in controlling speed changes, as it limits the amount of current induced in the rotor at high speeds, thereby preventing runaway conditions and ensuring the generator’s stability.

A Generator motor rotor core with superior magnetic properties, such as low hysteresis loss and high permeability, ensures that the rotor can maintain consistent rotational speed under varying loads. The dynamic response of the rotor core to load changes will determine how well the generator can compensate for sudden surges or drops in demand without significant fluctuations in output frequency or voltage. High-quality rotor cores that minimize eddy current losses and flux distortion help maintain consistent speed, providing better voltage regulation and frequency stability across varying load conditions.

3. Eddy Current Losses and Efficiency

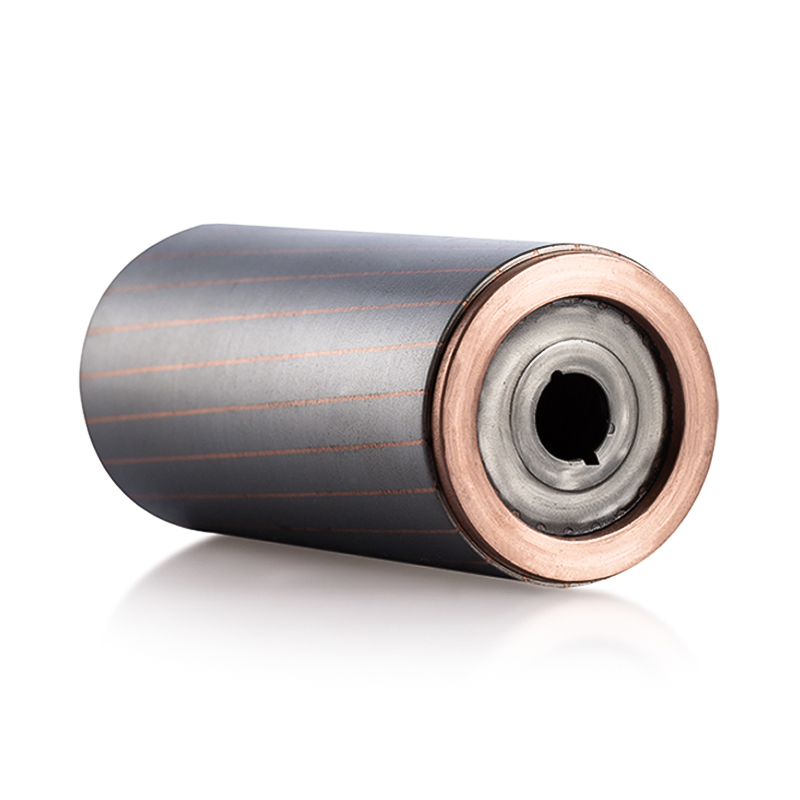

Eddy current losses are an inherent challenge in rotating electrical machines like generators. These losses occur when magnetic fields induce circulating currents within the rotor core, which leads to energy dissipation in the form of heat. These losses are particularly significant at higher rotor speeds, where the change in magnetic flux is greater and induces stronger eddy currents.

To mitigate this, the rotor core is often made from laminated silicon steel or other high-performance materials with low electrical conductivity. The lamination technique reduces the path for eddy currents, which in turn limits their formation and minimizes power loss. At high speeds, these materials ensure that the generator operates efficiently by reducing core heating and maintaining optimal power conversion. The design of the rotor core, including the number of laminations, their thickness, and the quality of the core material, all play a critical role in minimizing these losses. Efficient core design ensures that, under high load or speed conditions, the generator retains high electrical efficiency and thermal stability, preventing performance degradation due to excessive heat.

4. Thermal Management and Load Handling

Thermal management is one of the most critical factors influencing the performance of a generator’s rotor core, especially when it operates at high speeds or under heavy load conditions. As electrical energy is converted into mechanical energy, the rotor core generates heat due to resistive losses and eddy currents. Without adequate cooling, this heat buildup can cause thermal degradation of the core materials and magnetic saturation, which significantly reduces the generator's performance and lifespan.

A well-designed rotor core typically integrates cooling channels or uses forced air cooling systems to maintain optimal operating temperature. High-performance materials with superior thermal conductivity, such as copper or specialized alloys, are often used in rotor cores to enhance heat dissipation. The laminated design also assists in heat management by minimizing core loss, while careful attention to rotor geometry ensures that heat is evenly distributed across the core. Proper thermal management allows the generator to sustain high speeds and handle increased loads without risk of overheating, ensuring reliable operation across a broad range of operating conditions.

5. Stator and Rotor Synchronization

For a generator to operate efficiently across varying speeds, the rotor must remain electromagnetically synchronized with the stator’s rotating magnetic field. This synchronization ensures that the generator produces a stable output voltage and frequency. A well-designed rotor core optimizes this interaction by ensuring that the rotor's magnetic field is aligned with the stator field at both low and high speeds.

The core's material properties and geometry determine how easily the rotor's magnetic field interacts with the stator’s field, which impacts the generator's starting torque, speed stability, and load response. The rotor core must provide minimal magnetic resistance and maintain strong flux coupling between the rotor and stator to avoid loss of synchronization, which could lead to inefficiency, voltage instability, or even damage to the generator. In high-speed operation, the rotor core must be designed to handle transient changes in load while maintaining this synchronization, ensuring the generator remains stable during fluctuations.

简体中文

简体中文 English

English русский

русский Español

Español