How does the lamination thickness of an Automotive Small Motor Rotor Core impact eddy current losses and energy efficiency?

Fundamentals of Eddy Current Formation

When an Automotive Small Motor Rotor Core operates within a changing magnetic field, alternating magnetic flux penetrates the core material. This changing flux induces eddy currents—looped electrical currents circulating perpendicular to the magnetic field—within the conductive iron or steel. These eddy currents dissipate energy in the form of heat, which constitutes a core loss that reduces the overall electrical-to-mechanical efficiency of the motor. Excessive eddy currents can also elevate the rotor temperature, adversely affecting insulation systems, magnet performance, and rotor integrity. Laminating the rotor core is the primary engineering strategy to mitigate this effect.

Role of Laminations in Controlling Eddy Currents

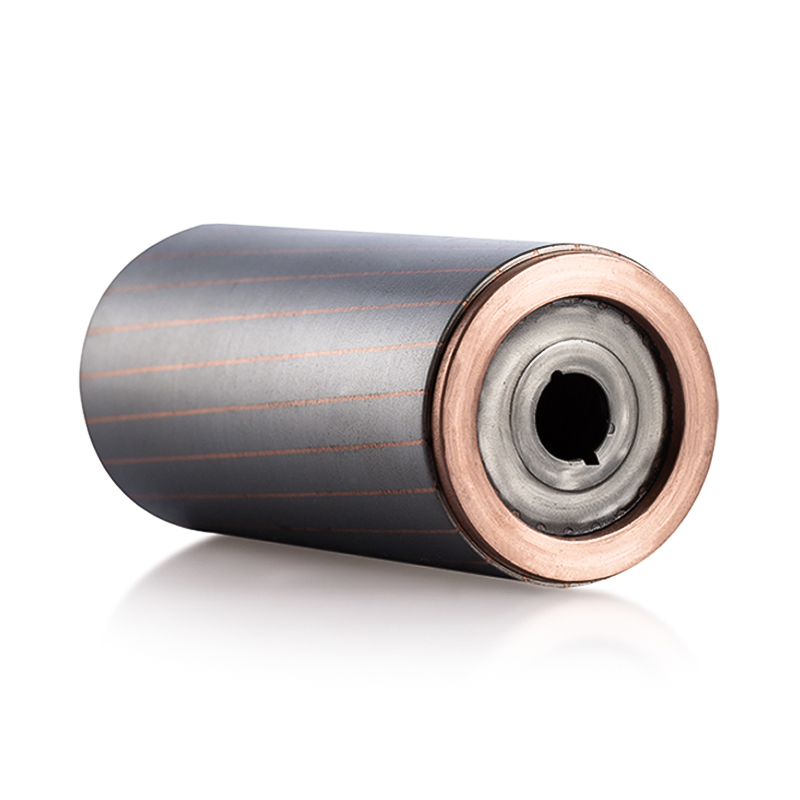

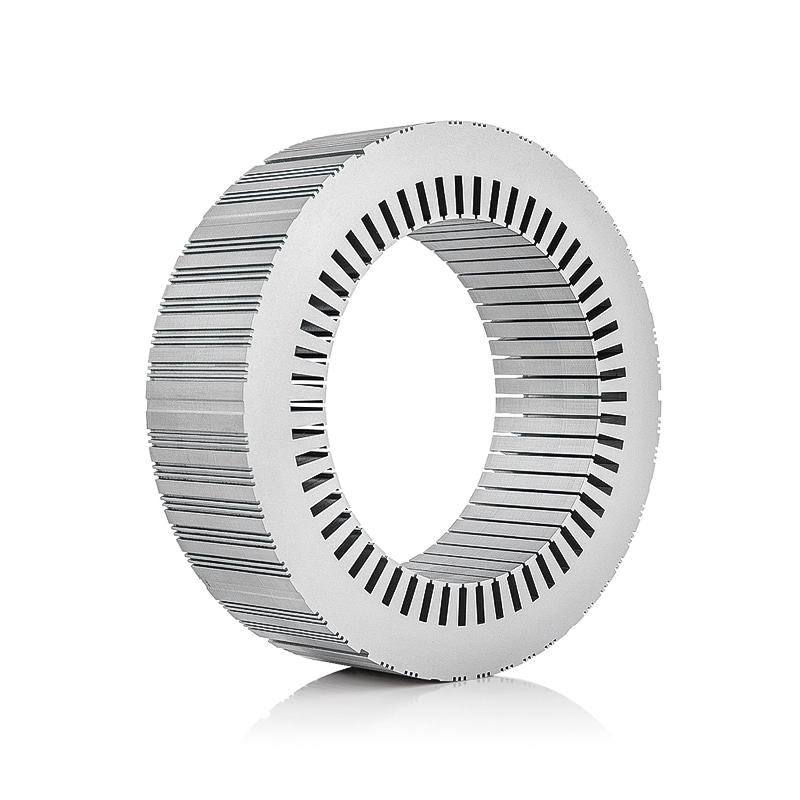

A rotor made of a solid piece of iron would allow eddy currents to flow freely over large cross-sectional areas, producing significant energy loss. To prevent this, Automotive Small Motor Rotor Cores are constructed from multiple thin sheets of electrical steel or silicon steel, each insulated from the next. These laminations constrain eddy currents to the thickness of a single sheet, effectively limiting the loop area for current flow. By reducing the magnitude of circulating currents, the lamination design minimizes internal heating, stabilizes thermal performance, and preserves energy that would otherwise be wasted as heat.

Impact of Lamination Thickness on Losses

The thickness of each lamination is a critical design parameter. Thinner laminations reduce the path available for eddy currents, thereby lowering energy losses. For example, in high-speed automotive applications, even small reductions in lamination thickness can significantly reduce eddy current losses due to the high frequency of flux changes. Conversely, thicker laminations allow larger circulating currents, increasing energy dissipation, core heating, and potential thermal stress on the rotor and stator assembly.

In small automotive motors—such as starter motors, hybrid drive motors, or auxiliary motors—operating at thousands of RPM, controlling eddy current losses is especially important. Designers must ensure that lamination thickness is optimized for both electrical performance and thermal stability, ensuring that the rotor operates efficiently under transient loads, high-speed conditions, and varying duty cycles.

Balance Between Efficiency and Manufacturing Practicality

While thinner laminations provide superior efficiency, they also introduce manufacturing challenges. Thinner sheets require more precise stamping, cutting, and handling to avoid deformation. Insulating coatings between laminations must remain intact to prevent short-circuits that could nullify the efficiency gains. Therefore, rotor core designers must carefully balance lamination thickness, material properties, and manufacturing feasibility. Selecting the optimal thickness ensures reduced eddy current losses while keeping production cost-effective and assembly reliable.

Effect on Energy Efficiency and Thermal Management

Reducing eddy current losses directly enhances motor energy efficiency. Less energy is wasted as heat, meaning that a greater proportion of electrical input is converted into mechanical output. In automotive applications, this translates to improved fuel efficiency for ICE vehicles, extended battery range for electric vehicles, and enhanced performance of hybrid drive systems. Lower heat generation also reduces thermal stress on rotor laminations, stator windings, and insulation materials, which increases the reliability and service life of the motor. Efficient thermal management ensures that the rotor can sustain high-speed operation without performance degradation.

简体中文

简体中文 English

English русский

русский Español

Español