How does the Motor Stator and Rotor Core contribute to motor startup performance and transient response?

-

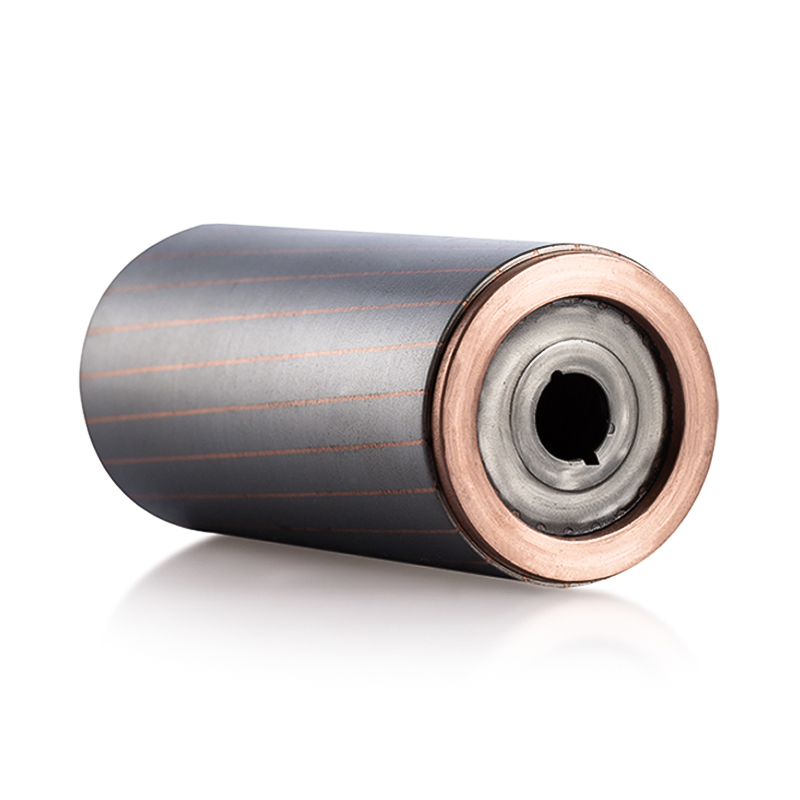

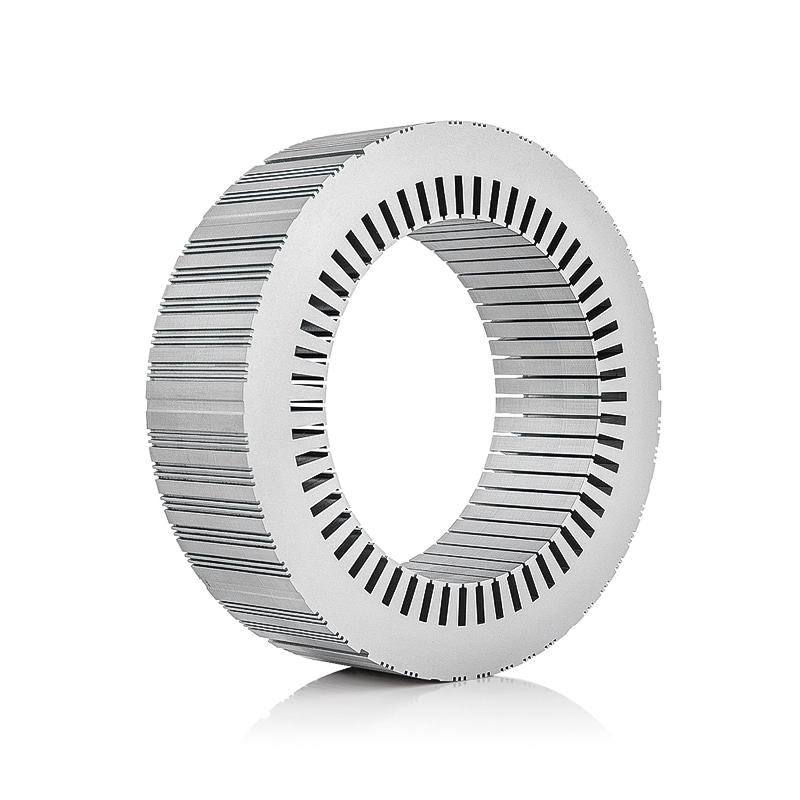

Electromagnetic Flux Generation and Initial Torque Production

The motor’s startup performance fundamentally relies on the ability of the Motor Stator And Rotor Core to generate and direct magnetic flux efficiently. When voltage is first applied, the stator windings create a magnetic field that induces current in the rotor, initiating torque generation. The design and material quality of the cores—specifically, their magnetic permeability, lamination structure, and overall geometry—determine how effectively this flux is established and transferred. A high-permeability, low-loss core allows the magnetic field to reach the rotor quickly, resulting in rapid torque buildup and swift acceleration from a standstill. In contrast, cores with lower magnetic efficiency or poorly designed laminations delay flux establishment, reducing startup torque and increasing the inrush current drawn from the power supply. Optimizing the magnetic path in both the stator and rotor ensures that the motor responds predictably and efficiently under initial voltage application, which is critical for applications requiring frequent starts or high-torque demands at low speed. -

Minimization of Eddy Current and Hysteresis Losses During Transients

During startup, the motor experiences rapidly changing magnetic fields as the rotor accelerates from zero speed. The stator and rotor cores must manage these transients effectively by minimizing eddy current and hysteresis losses. Laminated cores made of high-grade electrical steel, with insulation between layers, limit circulating currents that would otherwise dissipate energy as heat. Similarly, the core material’s low hysteresis loss ensures that the energy used to magnetize and demagnetize the steel during rapid flux changes is minimized. By reducing these losses, the cores allow more electrical energy to be converted directly into mechanical torque, resulting in faster acceleration and a more efficient startup process. Efficient core design also limits thermal buildup during repeated or prolonged startups, which can degrade performance and shorten motor life. -

Influence of Rotor and Stator Geometry on Dynamic Response

The geometry of the rotor and stator cores plays a key role in transient performance. Factors such as stator slot shape, rotor bar design (in induction motors), and lamination profile determine how magnetic flux interacts with the rotor during startup. Optimized slot geometry reduces localized flux concentrations, minimizes torque ripple, and ensures smooth torque production as the rotor begins to rotate. In permanent magnet and synchronous motors, rotor core geometry directly affects magnetic coupling and the rate at which torque is generated. Accurate alignment between stator and rotor laminations ensures uniform flux distribution, avoiding mechanical vibrations or oscillations during acceleration. By carefully designing the core geometry, engineers can create motors that deliver precise, repeatable torque from startup while maintaining mechanical stability and minimizing vibration. -

Magnetic Saturation Management

During the high-current startup phase, parts of the stator or rotor core can be exposed to magnetic fields approaching or exceeding their saturation point. If saturation occurs prematurely, the core cannot carry additional flux efficiently, which reduces the motor’s torque output and slows acceleration. Well-designed cores, using appropriate materials and lamination thickness, maintain a linear magnetic response throughout the startup transient. This ensures that torque generation remains predictable, inrush currents are controlled, and the rotor accelerates smoothly to operational speed. Avoiding saturation also reduces the risk of localized heating and stress on both the core and the windings. -

Thermal Management and Energy Efficiency

Rapid changes in magnetic flux during startup produce localized heating in the cores due to eddy currents and hysteresis effects. Core materials with high thermal conductivity and efficient lamination structures help dissipate this heat quickly, preventing temperature spikes that could damage insulation or reduce efficiency. Effective thermal management ensures that the motor can perform repeated startups without overheating, maintaining both performance and longevity. In addition, minimizing losses during startup contributes to higher energy efficiency, as less electrical energy is wasted as heat and more is converted to mechanical output.

简体中文

简体中文 English

English русский

русский Español

Español