Automotive Electric Motor Rotor and Stator Core Selection Guide: Aluminum vs. Steel

The Importance of Material Selection for Rotor and Stator Cores in Electric Vehicle Motors

In the design of electric vehicle (EV) motors, material selection is a pivotal factor influencing the motor’s performance, efficiency, weight, and overall cost. Among the many components of an EV motor, the rotor and stator cores are especially critical, as they directly interact with the motor’s electromagnetic fields to convert electrical energy into mechanical power. The core materials for these components must be carefully chosen to optimize performance characteristics such as power density, thermal management, and electromagnetic efficiency.

Aluminum and steel are the two most commonly used materials for rotor and stator cores, each offering distinct advantages and applications depending on the specific design and operational requirements of the motor. The choice of material impacts several factors, including the motor’s efficiency, operating temperature, weight, and manufacturing cost.

1. Role of Rotor and Stator Cores in EV Motors

Before diving into the specifics of material selection, it’s important to understand the role that the rotor and stator cores play in an EV motor.

-

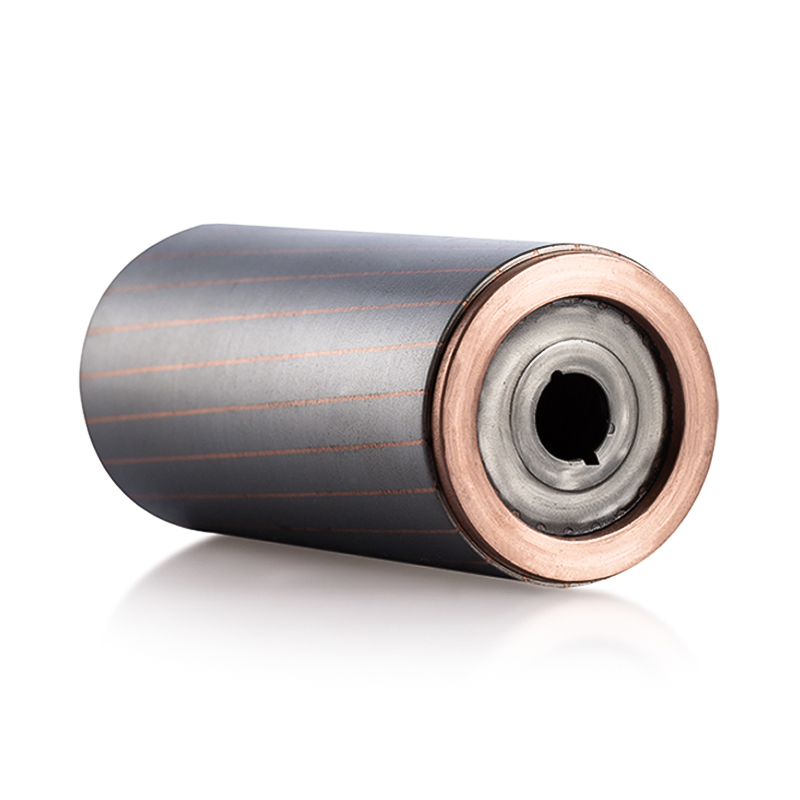

Rotor Core: The rotor is the rotating part of the motor, which is connected to the shaft and is driven by the magnetic field generated by the stator. The rotor core must be designed to handle the torque and rotational speed while minimizing losses like eddy currents and hysteresis.

-

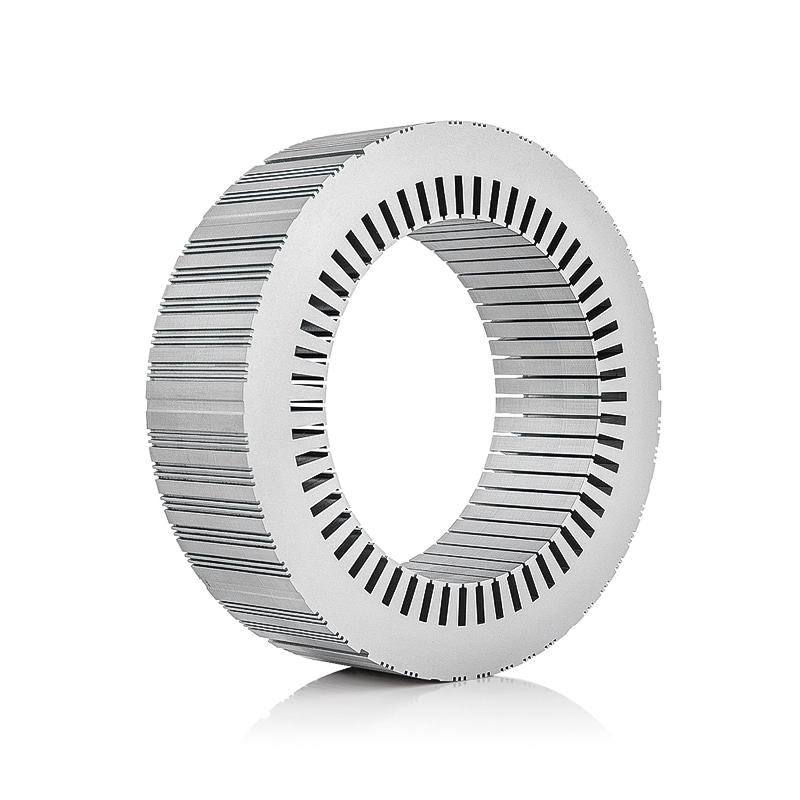

Stator Core: The stator is the stationary part of the motor and consists of windings through which the electric current flows. It generates a magnetic field that interacts with the rotor’s magnetic field, causing the rotor to spin. The stator core must be designed to support the windings and facilitate efficient magnetic flux generation.

Both the rotor and stator cores are typically made from laminated steel or aluminum, with laminated sheets used to reduce energy losses caused by eddy currents. The core materials must have excellent magnetic properties, high thermal stability, and low electrical resistance.

2. Steel in Rotor and Stator Cores

Steel, particularly silicon steel, is the traditional and most widely used material for rotor and stator cores in electric vehicle motors. Silicon steel is a type of steel that contains silicon to enhance its magnetic properties, making it more suitable for high-performance motor applications. The key benefits of using steel in these motor components include its high magnetic permeability, strength, and thermal resistance.

2.1. High Magnetic Permeability

The magnetic permeability of steel is significantly higher than that of aluminum. This means that steel can conduct magnetic fields more efficiently, which directly influences the motor’s efficiency and power density. The rotor and stator cores made from high-permeability steel ensure that the motor can generate strong, stable magnetic fields, resulting in greater power output and overall motor performance.

In electric motors that require high torque and power output, such as those found in electric sedans, SUVs, and trucks, steel’s high magnetic permeability makes it the preferred material for rotor and stator cores. The improved efficiency in converting electrical energy to mechanical energy translates to better overall performance and increased range.

2.2. Strength and Durability

Steel is inherently strong and durable, which makes it suitable for motors that experience high stresses and demanding operating conditions. The rotor and stator cores made from steel can withstand mechanical forces and high temperatures without losing structural integrity.

For high-performance EVs, where the motor is subjected to intense rotational forces and high-speed operation, steel’s strength ensures long-term durability. Steel’s resistance to deformation also helps the motor maintain its performance even under extreme conditions.

2.3. Thermal Resistance

Steel’s ability to withstand high temperatures is another advantage. During operation, electric motors generate heat due to the conversion of electrical energy into mechanical energy. Steel’s high thermal stability ensures that it can operate efficiently without degradation at higher temperatures, which is essential for motors in high-performance applications.

In contrast, aluminum tends to lose strength at elevated temperatures more rapidly than steel. Steel-based rotor and stator cores can handle the heat generated in high-performance motors, preventing overheating, which could otherwise lead to failure or reduced motor life.

2.4. Eddy Current Losses and Hysteresis

While steel provides excellent magnetic properties, one of its drawbacks is eddy current losses. When the rotor and stator cores are exposed to alternating magnetic fields, circulating currents (eddy currents) can be induced within the core material. These currents generate unwanted heat and energy losses. To minimize these losses, steel cores are typically laminated to increase the resistance to eddy currents.

Steel also experiences hysteresis losses due to the lag in the magnetic field’s response to changes in the electrical current. However, modern steel alloys, such as grain-oriented silicon steel, are engineered to reduce these losses, improving overall efficiency.

3. Aluminum in Rotor and Stator Cores

Aluminum is a lighter, more cost-effective alternative to steel. While it doesn’t match steel in terms of magnetic properties or thermal resistance, aluminum has its advantages, particularly in applications where weight reduction is a priority.

3.1. Lightweight and Reduced Mass

One of the most significant advantages of aluminum is its lightweight nature, which reduces the overall mass of the motor. In the context of electric vehicles, reducing weight is critical for improving vehicle range, efficiency, and performance.

For urban electric cars and hybrid vehicles, where reducing the overall weight of the motor can result in substantial improvements in energy efficiency, aluminum is a preferred choice for the rotor and stator cores. Lightweight motors help reduce the energy required to accelerate and decelerate the vehicle, increasing battery life and driving range.

3.2. Lower Manufacturing Cost

Aluminum is typically less expensive than steel, both in terms of raw material costs and manufacturing processes. It is also easier to shape and process, which can further lower the cost of producing EV motors.

In more cost-sensitive applications, such as budget electric cars or entry-level hybrid vehicles, aluminum can be a good choice for rotor and stator cores. While the motor may not achieve the same level of performance as one with steel cores, it can still provide adequate efficiency at a lower price point.

3.3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to the air, giving it excellent corrosion resistance. This makes it suitable for motors that will be exposed to various environmental conditions, such as high humidity or salty air (e.g., coastal regions).

In applications where the vehicle might operate in less-than-ideal environmental conditions, such as in areas with high moisture or extreme weather, aluminum rotor and stator cores help increase the motor’s durability and reliability.

3.4. Lower Magnetic Permeability and Efficiency

One of the key drawbacks of aluminum in rotor and stator cores is its low magnetic permeability compared to steel. This means that aluminum is less effective at conducting magnetic fields, which can result in lower efficiency and power density. Motors with aluminum cores may require larger cross-sectional areas or higher current densities to achieve the same power output as motors made from steel.

For lightweight electric vehicles with relatively low power demands, aluminum can still provide sufficient performance, but for high-performance applications where efficiency and power output are critical, steel remains the material of choice.

4. Comparison of Steel and Aluminum for Rotor and Stator Cores

To help clarify the differences between aluminum and steel in the context of rotor and stator cores, here’s a summary comparison of their key properties:

| Property | Aluminum | Steel |

|---|---|---|

| Magnetic Permeability | Low: Less efficient in conducting magnetic fields. | High: Highly efficient at conducting magnetic fields. |

| Weight | Lightweight: Reduces overall motor and vehicle weight. | Heavier: Increases motor and vehicle weight. |

| Cost | Lower: Cost-effective and cheaper to manufacture. | Higher: More expensive due to superior magnetic properties and manufacturing processes. |

| Thermal Resistance | Moderate: Susceptible to thermal degradation at high temperatures. | High: Can withstand high temperatures without loss of strength. |

| Durability | Moderate: May not withstand high mechanical stresses as well as steel. | High: Durable and can handle high mechanical stresses. |

| Corrosion Resistance | High: Naturally resistant to corrosion. | Moderate: Steel requires coatings to resist corrosion. |

1. Basic Structure of Electric Vehicle Motors

Before delving into the comparison between aluminum and steel, it is essential to understand the fundamental components that make up an electric vehicle motor. The motor’s performance, efficiency, and durability are largely influenced by its basic structure, which includes two key parts: the stator and the rotor.

Stator: The Stationary Part of the Motor

The stator is the static component of the electric motor, meaning it does not rotate. It is typically made up of windings (coils) of wire and a magnetic core. Together, these elements generate a rotating magnetic field that induces a torque on the rotor.

Stator Windings (Coils)

The windings in the stator are usually made from copper or aluminum wire and are wound into coils. These coils are connected to an external power source that supplies alternating current (AC) or direct current (DC), depending on the type of motor. When current flows through these windings, they create an electromagnetic field. The alternating current causes the direction of the magnetic field to reverse periodically, generating a rotating magnetic field.

The rotating magnetic field produced by the stator is what drives the rotor, which will eventually generate mechanical energy. In the case of an AC motor, this rotating magnetic field is responsible for the continuous rotation of the rotor, while in a DC motor, the current is directed through the stator windings in such a way as to create a steady magnetic field.

Stator Core: High Magnetic Permeability for Efficiency

The stator core plays a critical role in ensuring the efficient conversion of electromagnetic energy. It is typically made of laminated steel sheets or other materials with high magnetic permeability. The laminated design helps reduce eddy current losses and minimizes the waste heat generated in the stator.

The core material must possess certain characteristics:

- High Magnetic Permeability: This allows the stator to conduct magnetic flux effectively, which improves the motor’s efficiency by reducing energy loss.

- Low Hysteresis Loss: The stator core must also have low hysteresis loss, meaning it retains minimal residual magnetism when the magnetic field changes direction. This is particularly important for AC motors, where the magnetic field is continually reversing.

The stator core is typically designed with a laminated structure to mitigate eddy current losses. The thinner the laminations, the less resistance they provide to the current, which improves motor efficiency.

Rotor: The Rotating Part of the Motor

The rotor is the part of the motor that rotates within the stator’s magnetic field, generating mechanical energy. It typically consists of conductive materials like copper, aluminum, or iron that are arranged to interact with the stator’s rotating magnetic field.

Rotor Construction and Materials

The rotor is often made of materials with high conductivity, as this allows it to generate and maintain a strong electromagnetic field in response to the stator’s rotating magnetic field. Depending on the motor type, the rotor can be designed in several ways:

- Squirrel Cage Rotor: The most common rotor design, particularly for induction motors, consists of laminated steel rings with short-circuited bars (often copper or aluminum). This design is highly efficient and durable, making it ideal for most electric vehicle motors.

- Wound Rotor: Some motors, particularly in larger industrial applications, use a wound rotor. In this design, the rotor windings are connected to external resistors or controllers that can adjust the rotor’s resistance for better control.

The rotor’s material choice significantly impacts its strength, efficiency, and heat resistance. Materials like aluminum are often used in high-speed applications, while copper may be used in motors where higher power output is required. Iron cores are frequently used for their magnetic properties, although these are generally heavier than alternatives.

Rotor Core: Strength and Stability

The rotor core must be designed to provide both strength and stability, especially under high load and rotational speeds. In addition to materials like copper and aluminum, the rotor’s core may be reinforced with steel or other materials that enhance durability.

The core material must be:

- Magnetically Active: Just like the stator core, the rotor core must also have high magnetic permeability to ensure efficient energy conversion.

- Heat Resistant: The rotor experiences significant heating due to the rotational speed and the electromagnetic forces acting on it. Therefore, the rotor core must be able to withstand high temperatures without deforming or losing its magnetic properties.

- Durable Under High Loads: The rotor’s design must be robust enough to handle the mechanical stresses of continuous high-speed rotation and torque.

Stator and Rotor Interaction

The interaction between the stator’s rotating magnetic field and the rotor’s conductive materials generates the torque that powers the vehicle’s drivetrain. This interaction is at the heart of the motor’s ability to convert electrical energy into mechanical energy.

- Induction Motors: In induction motors, the stator generates a rotating magnetic field that induces a current in the rotor, which in turn generates its own magnetic field. The interaction between these magnetic fields results in a rotational force (torque).

- Permanent Magnet Motors: In permanent magnet motors, the stator’s magnetic field interacts with the magnets embedded in the rotor, creating a torque.

The rotor’s performance is highly dependent on the quality of the materials used for both the conductive winding and the core. High-performance materials such as copper and aluminum help optimize efficiency, while steel provides the necessary strength and stability for high-load applications.

Material Comparison of Stator and Rotor Cores

The choice of material for the stator and rotor cores has a direct impact on the motor’s overall performance. Below is a simple comparison of the core materials used in stators and rotors:

| Property | Aluminum | Steel |

|---|---|---|

| Weight | Lightweight | Heavier, suitable for strength |

| Electrical Conductivity | High | Lower |

| Magnetic Permeability | Moderate | High, optimal for magnetic flux |

| Heat Resistance | Moderate | High, suitable for high-power motors |

| Corrosion Resistance | Excellent | Requires coating for rust protection |

| Cost | More Expensive | More Cost-Effective |

2. Application of Aluminum and Steel in Motor Cores

In the automotive industry, the materials used in electric motor cores play a critical role in determining the efficiency, performance, and durability of motors. The stator and rotor cores of automotive motors are two of the most crucial components. These cores are responsible for generating the magnetic fields that facilitate the conversion of electrical energy into mechanical energy. The choice of material used in the construction of these cores impacts a variety of factors, including motor weight, power output, efficiency, and cost. Two of the most common materials used in the construction of automotive motor stator and rotor cores are aluminum and steel. Each material has its own set of advantages and disadvantages that must be carefully considered based on the specific needs of the motor and the application.

Aluminum: Lightweight and High Conductivity

Aluminum is one of the most popular materials used in the automotive motor cores, particularly for applications where reducing weight is a primary concern. Aluminum’s characteristics make it a valuable option for electric vehicles (EVs) and other automotive applications where performance, efficiency, and long-term durability are important factors.

Advantages of Aluminum in Motor Cores

-

Lightweight:

One of the most significant benefits of using aluminum in automotive motor stator and rotor cores is its lightweight nature. Aluminum’s density is about one-third that of steel, which means that a motor constructed with aluminum will weigh significantly less. This reduced weight is particularly advantageous in electric vehicles, where every kilogram saved can lead to an increase in driving range and performance. In a market where reducing the weight of EVs is key to improving overall vehicle efficiency, the use of aluminum can contribute to a more efficient and effective motor design. -

Good Electrical Conductivity:

Aluminum also boasts excellent electrical conductivity. This property makes it an ideal material for electric motors, where reducing electrical losses is critical to improving the efficiency of the motor. In automotive motor stator and rotor cores, aluminum’s conductivity can reduce the amount of energy wasted during operation. This improves the overall performance of the motor, especially in electric vehicles where efficiency directly impacts the vehicle’s driving range and power output. -

Corrosion Resistance:

Another key advantage of aluminum is its inherent corrosion resistance. Unlike steel, which can rust over time when exposed to moisture, aluminum naturally forms a protective oxide layer when exposed to air, which prevents further corrosion. This makes aluminum a suitable material for automotive motor cores that may be exposed to harsh environments, such as high humidity or saltwater, where rust and corrosion could otherwise impair the motor’s performance and longevity. By using aluminum in the motor’s stator and rotor cores, manufacturers can increase the lifespan of the motor and reduce maintenance requirements.

Disadvantages of Aluminum in Motor Cores

-

Lower Strength and Heat Resistance:

While aluminum offers excellent electrical conductivity and corrosion resistance, it does come with some drawbacks. Aluminum has lower mechanical strength and heat resistance compared to steel, which can limit its performance in certain high-load, high-speed applications. Under extreme conditions, such as high torque or high temperatures, aluminum may experience thermal expansion or even deformation. This could compromise the efficiency of the motor and its ability to perform consistently over time. -

Higher Cost:

Although aluminum itself is relatively inexpensive compared to many other materials, its manufacturing and processing costs can be higher than steel. Aluminum is more challenging to machine and shape into the required components for automotive motor cores, which increases production costs. For manufacturers seeking to minimize costs, steel may be a more cost-effective option. This higher cost of aluminum could ultimately affect the overall affordability of electric vehicles and other automotive applications that use aluminum-based motor cores.

Steel: High Strength and Durability

Steel is another material commonly used in automotive motor stator and rotor cores, particularly for applications where high strength, heat resistance, and overall durability are essential. Steel offers a range of advantages that make it a viable alternative to aluminum, especially in more demanding motor applications.

Advantages of Steel in Motor Cores

-

High Strength and Heat Resistance:

One of the most significant benefits of steel in automotive motor cores is its high strength and exceptional heat resistance. Steel can withstand much higher temperatures than aluminum without undergoing thermal expansion or deformation. This makes it an ideal choice for automotive motors that need to operate under high-load and high-torque conditions, such as those found in performance or heavy-duty electric vehicles. Steel’s strength also makes it a better choice for motors that require higher levels of mechanical stability and reliability over time. -

Lower Cost:

Compared to aluminum, steel is generally more affordable, both in terms of raw material cost and processing. The manufacturing techniques for steel are well-established, and steel is easier to shape and machine into motor core components. For automotive manufacturers looking to reduce production costs, steel offers a more budget-friendly option without compromising on the motor’s core functionality. Steel is also widely available, making it a convenient and cost-effective choice for mass production. -

Higher Magnetic Permeability:

Another important property of steel is its higher magnetic permeability compared to aluminum. Magnetic permeability refers to a material’s ability to conduct magnetic fields, which directly impacts the performance of electric motors. Steel’s higher magnetic permeability means it can enhance the motor’s efficiency and power density. In applications where strong magnetic fields are necessary—such as high-performance electric motors—steel is the preferred material because it can effectively support the motor’s magnetic flux.

Disadvantages of Steel in Motor Cores

-

Heavier Weight:

While steel’s strength and heat resistance are major advantages, the material is considerably heavier than aluminum. The higher density of steel results in a heavier motor, which can impact the performance of electric vehicles. In particular, heavier motors reduce the vehicle’s range and acceleration, as more energy is required to move the additional weight. For applications where minimizing weight is a top priority, the use of steel in the motor cores may not be ideal. -

Prone to Rust:

Steel, unlike aluminum, is prone to rusting when exposed to moisture and air. To prevent this, steel components in automotive motor cores must undergo additional processing, such as coating or galvanizing, to ensure they remain corrosion-resistant. If steel motor cores are not properly protected from corrosion, it can lead to reduced motor efficiency, increased wear, and a shortened lifespan. This makes steel a less appealing choice in environments where corrosion is a significant concern, such as coastal areas with high humidity or vehicles exposed to saltwater.

Comparison Table: Aluminum vs. Steel in Automotive Motor Cores

| Property | Aluminum | Steel |

|---|---|---|

| Density | Low (about one-third of steel) | High (about three times that of aluminum) |

| Electrical Conductivity | Good (reduces motor losses and increases efficiency) | Moderate (less efficient for electrical applications) |

| Mechanical Strength | Lower (may deform under high stress) | Higher (excellent strength for high-load conditions) |

| Heat Resistance | Moderate (may expand or deform under heat) | High (can withstand higher temperatures) |

| Corrosion Resistance | Excellent (natural oxide layer) | Poor (requires coating to prevent rust) |

| Cost | Higher (due to manufacturing and processing) | Lower (more affordable material and process) |

| Magnetic Permeability | Moderate | High (better for motor efficiency and power density) |

| Weight | Light (ideal for electric vehicles) | Heavy (can impact performance in EVs) |

3.Aluminum vs. Steel: Performance Comparison

In the world of manufacturing and engineering, choosing the right material for a given application is crucial for ensuring the optimal performance of a product. Two materials that are frequently compared for various industrial uses are aluminum and steel. Both have distinct characteristics that influence their selection in motor construction, automotive components, structural frameworks, and many other sectors. This comparison focuses on key performance metrics, including density, electrical conductivity, strength, corrosion resistance, cost, magnetic permeability, and heat resistance.

Density: Weight Considerations for Efficiency

One of the most important factors when selecting a material for various engineering applications is its density. Density refers to the mass per unit volume of a material, and it has a significant impact on the overall weight of the component being produced.

Aluminum is known for its low density, which is approximately 2.7 g/cm³, making it one of the lightest structural metals. This lower density is a major advantage when it comes to applications where weight reduction is critical, such as in the aerospace, automotive, and electric vehicle (EV) industries. Lighter components result in reduced fuel consumption, higher energy efficiency, and better overall performance of vehicles, particularly for electric motors. In electric vehicles, for example, reducing the weight of the motor and other components directly impacts battery life and range.

On the other hand, Steel has a much higher density, approximately 7.8 g/cm³. This increase in density directly correlates to an increase in weight. While this might be a disadvantage in applications requiring lightness, it can be an advantage in industries where weight is not a primary concern, or even in cases where additional mass may be beneficial for stability, durability, or strength. Steel’s higher weight is often preferred in construction, heavy machinery, and other sectors that require materials capable of bearing significant loads.

Electrical Conductivity: Impact on Motor Efficiency

When it comes to electrical applications, the ability of a material to conduct electricity plays a critical role in the overall performance of electric motors, transformers, and other electrical components.

Aluminum offers good electrical conductivity. Its conductivity is around 61% of that of copper, but because aluminum is much lighter, it often proves to be a more cost-effective alternative, especially when considering the need for lighter components in motors. Its lower resistivity contributes to reduced motor losses, enhancing the efficiency of electric motors. This is one of the reasons why aluminum is frequently used in power lines, rotor windings, and other components where weight and electrical performance are essential.

In contrast, Steel has poor electrical conductivity compared to aluminum. Its resistivity is higher, which leads to more energy loss in electrical components. In electric motors or transformers, steel can contribute to increased heat generation and reduced overall efficiency due to these higher motor losses. For these reasons, while steel can be used in some electrical applications, it’s typically not the material of choice when minimizing losses and maximizing efficiency is a priority.

Strength: Suitability for Different Applications

Strength is a critical factor when selecting materials for components that must withstand heavy loads, mechanical stress, and high-speed operations.

Aluminum is relatively weaker than steel, with a tensile strength that ranges from 90 to 570 MPa depending on the alloy used. While aluminum’s strength is sufficient for light-load applications, it is not suitable for situations that require high structural integrity or the ability to withstand heavy forces. As such, aluminum is more commonly used in industries where weight reduction is more important than absolute strength, such as in aircraft, lightweight vehicles, and certain sporting equipment.

Steel, on the other hand, offers significantly higher strength, with tensile strengths ranging from 400 MPa for mild steel to more than 2,000 MPa for high-strength alloys. This makes steel ideal for heavy-duty applications, including construction, automotive frameworks, and high-speed machinery. Steel’s robustness is crucial in industries that require materials to perform under high-stress conditions, such as in bridges, buildings, and high-performance motors.

Corrosion Resistance: Durability in Harsh Environments

Corrosion resistance is another critical consideration in material selection, especially for components exposed to moisture, chemicals, or other harsh environmental conditions.

Aluminum has excellent corrosion resistance due to the natural formation of a thin oxide layer that protects the surface from further degradation. This layer helps aluminum resist oxidation and corrosion in most environments. As a result, aluminum components typically require minimal protection or additional coatings. Its natural resistance to corrosion makes it an excellent choice for applications in marine environments, outdoor equipment, and other areas exposed to the elements.

Steel, however, is more prone to corrosion, especially when exposed to moisture and air. The presence of iron in its composition makes steel highly susceptible to rust formation. As a result, steel components usually require protective coatings such as paint, galvanization, or corrosion inhibitors to prolong their lifespan. In harsh environments, regular maintenance and protective measures are often necessary to ensure the durability of steel components.

Cost: Budgeting for Material Choice

When it comes to overall material costs, Aluminum is generally more expensive than steel. The higher cost of aluminum stems from both its extraction and processing methods. Producing aluminum requires energy-intensive processes, and its refining and manufacturing tend to be more costly than steel. Additionally, aluminum’s higher price point can be attributed to its specialized applications and advantages in weight-sensitive industries.

Steel, on the other hand, is much more cost-effective in comparison. The cost of steel is relatively low due to the widespread availability of iron ore and the more established and efficient processes for manufacturing steel. The lower cost of steel makes it the preferred choice for a wide range of industrial applications, from construction to automotive manufacturing, where the weight is less critical than strength and durability.

Magnetic Permeability: Importance in Electromagnetic Applications

Magnetic permeability is an important property when selecting materials for applications involving magnetic fields, such as electric motors, transformers, and magnetic shielding.

Aluminum has average magnetic permeability, which means it does not perform as well in high-magnetic field applications. It is not suitable for situations where strong magnetic fields need to be channeled or concentrated. In applications such as electric motors, where efficient magnetic field generation is important, aluminum is often used in conjunction with other materials but is not a primary choice for the core or components directly responsible for magnetic performance.

Steel, on the other hand, has a high magnetic permeability, especially in the case of certain alloys like silicon steel. This property makes steel ideal for use in high-magnetic field environments. Steel is commonly used for the cores of electric motors and transformers, where high magnetic permeability is necessary to efficiently direct and concentrate magnetic flux.

Heat Resistance: Performance in Extreme Temperatures

Heat resistance is crucial for components exposed to high temperatures, especially in high-performance motors, industrial machinery, and automotive applications.

Aluminum has relatively poor heat resistance compared to steel. It begins to soften and deform at temperatures around 200°C, making it unsuitable for applications where components are exposed to high levels of heat. In applications such as engine blocks, high-performance motors, or components subject to intense thermal cycling, aluminum may not provide the necessary durability. However, aluminum’s heat dissipation properties are useful in certain scenarios, such as heat exchangers and cooling systems.

Steel offers much better heat resistance. High-grade steel alloys can withstand temperatures in excess of 500°C without significant loss of strength. This makes steel the material of choice for components used in high-heat environments, such as exhaust systems, engine components, and industrial furnaces. Steel’s ability to maintain its structural integrity under extreme temperatures allows it to perform well in demanding applications where heat exposure is unavoidable.

Performance Comparison Table

Here is a detailed comparison between aluminum and steel based on key performance metrics:

| Performance Metric | Aluminum | Steel |

|---|---|---|

| Density | Low, reduces motor weight | High, increases motor weight |

| Electrical Conductivity | Good, reduces motor losses | Poor, increases motor losses |

| Strength | Lower, suitable for light-load applications | High, suitable for high-load, high-speed applications |

| Corrosion Resistance | Excellent, minimal protection needed | Poor, requires rust protection |

| Cost | Higher, especially in processing | Lower, more cost-effective to manufacture |

| Magnetic Permeability | Average | High, suitable for high-magnetic field applications |

| Heat Resistance | Poor, may deform under high temperatures | Good, performs well in high-heat environments |

4.When to Use Aluminum and When to Use Steel in Electric Vehicle Motors

The choice between aluminum and steel for electric vehicle (EV) motors is crucial because the materials directly affect the performance, efficiency, weight, and cost of the vehicle. The selection depends on various factors such as the vehicle type, application requirements, and performance expectations.

1. Overview of Aluminum and Steel in EV Motors

When designing an electric vehicle, the motor is a key component that directly influences both the performance of the vehicle and its efficiency. The motor needs to be carefully designed, choosing materials that will optimize its function in different use cases. Aluminum and steel are two of the most commonly used materials for constructing these motors.

Both materials offer distinct advantages, but they also have limitations. In order to make an informed decision, it is essential to understand the core differences between these materials, particularly their magnetic properties, weight, thermal properties, and strength.

Aluminum: Lightweight and Cost-Effective

Aluminum is a non-ferrous metal with several benefits, such as its light weight, corrosion resistance, and ease of manufacturing. When used in electric vehicle motors, aluminum helps to reduce the overall weight of the motor and improve energy efficiency by decreasing the energy required to move the vehicle. It is particularly advantageous in applications where reducing the weight of the vehicle is critical, like in electric urban cars and hybrid vehicles.

Steel: High Strength and Efficiency

Steel, on the other hand, is a ferrous metal known for its durability, strength, and excellent magnetic properties. Steel offers superior magnetic permeability compared to aluminum, making it highly efficient in high-performance motors. Steel’s ability to withstand high temperatures without significant degradation is another key reason why it is used in high-performance electric motors, such as those found in electric sedans, SUVs, and other high-power applications.

2. When to Choose Aluminum for EV Motors

Aluminum has many qualities that make it an excellent material for certain EV motor applications. Here are the scenarios where aluminum is preferred:

2.1. Lightweight Design and Efficiency

One of the primary reasons aluminum is chosen for EV motors is its light weight. Aluminum is about one-third the weight of steel, which means that it can significantly reduce the overall weight of the motor and the vehicle itself.

In urban electric vehicles, where the goal is to optimize energy efficiency by reducing weight, aluminum motors offer significant advantages. Lightweight motors reduce the total energy required to propel the vehicle, thereby increasing driving range. This is especially important for short-range vehicles or hybrid vehicles where fuel economy is paramount.

Key Benefits of Aluminum in EV Motors:

- Reduced weight leads to improved efficiency and longer battery life.

- Cost-effective compared to high-performance materials.

- Ease of manufacturing, reducing production costs and time.

- Good corrosion resistance, which is essential for long-term reliability in various weather conditions.

2.2. Motor Load is Relatively Light

Aluminum is ideal when the motor’s load is not exceptionally high. For example, in smaller electric vehicles (such as compact city cars) that do not require extremely high torque or high-speed capabilities, aluminum motors perform efficiently. In these cases, the motor doesn’t need to operate under extreme conditions, and aluminum provides adequate power without the added cost or weight of using steel.

2.3. Suitable for Low-Temperature Applications

Although aluminum does not perform as well as steel in extremely high-temperature environments, it is effective in moderate temperature ranges. For electric vehicles that operate in milder climates or do not require heavy-duty cooling systems, aluminum offers good thermal management properties.

3. When to Choose Steel for EV Motors

Steel is often the preferred material in situations where motor performance is critical, especially in high-power or high-speed applications. It offers several advantages in specific EV motor scenarios.

3.1. High Strength and Performance Demands

Steel is known for its strength and durability. When high torque, high power, and high speed are required—such as in performance electric vehicles (e.g., electric sedans, SUVs, and sports cars)—steel is the material of choice. Steel’s high magnetic permeability allows it to support high-performance motors that require stable operation under heavy load conditions.

Key Benefits of Steel in EV Motors:

- High strength enables motors to handle larger loads.

- Excellent magnetic properties improve motor efficiency.

- Thermal resistance helps the motor perform under high-temperature conditions.

- Better fatigue resistance for heavy-duty applications.

3.2. High-Temperature Performance

Electric motors in high-performance vehicles often operate under conditions where the temperatures can rise significantly. Steel’s ability to resist heat degradation is one of its major advantages. It can maintain its structural integrity at higher temperatures compared to aluminum, which is more susceptible to heat-related issues such as warping or loss of strength.

For motors that need to endure high heat, such as those in larger electric SUVs or long-distance trucks, steel ensures the motor will function properly without overheating or suffering from thermal fatigue.

3.3. High Magnetic Permeability for Efficiency

Steel has a higher magnetic permeability than aluminum, which makes it the ideal material for improving the efficiency and power density of the motor. Steel’s ability to conduct magnetic fields more effectively helps increase the power output of motors. As a result, electric motors made from steel tend to be more efficient in converting electrical energy into mechanical power, which is critical for high-performance EVs that demand more power.

4. Comparison of Aluminum and Steel for Electric Vehicle Motors

To make a clearer decision, let’s compare the two materials based on key performance metrics.

| Property | Aluminum | Steel |

|---|---|---|

| Weight | Lightweight: Reduces overall vehicle weight, improving efficiency. | Heavier: Increases vehicle weight but provides greater strength. |

| Strength | Moderate: Suitable for lighter loads. | High: Ideal for heavy-duty applications and high torque. |

| Magnetic Permeability | Moderate: Suitable for lower power motors. | High: Increases efficiency and power density in high-performance motors. |

| Thermal Resistance | Moderate: Adequate for low-temperature environments. | High: Excellent for high-temperature applications, such as in sports cars and trucks. |

| Cost | Lower: More affordable due to ease of manufacturing. | Higher: Typically more expensive due to the increased strength and performance characteristics. |

| Corrosion Resistance | High: Naturally resistant to corrosion. | Moderate: Requires additional coatings for corrosion resistance. |

简体中文

简体中文 English

English русский

русский Español

Español