How do the windings in the Servo Motor Stator interact with the rotor core, and what impact do they have on motor performance and efficiency?

Principle of Electromagnetic Induction

The interaction between the windings in the servo motor stator and rotor core is fundamentally governed by electromagnetic induction. When an electric current is passed through the stator windings, it generates a magnetic field that interacts with the rotor core. This magnetic field induces a current in the rotor and creates torque, causing the rotor to turn. The key to efficient motor performance lies in how effectively this magnetic interaction is managed. The rotor core is typically constructed from materials like laminated steel or magnetic alloys to minimize eddy current losses, which occur when the changing magnetic field induces circulating currents that generate heat and reduce efficiency. In this context, electromagnetic induction is a continuous process that sustains rotational motion in the motor, with the stator windings providing the energy input and the rotor translating that energy into mechanical output.

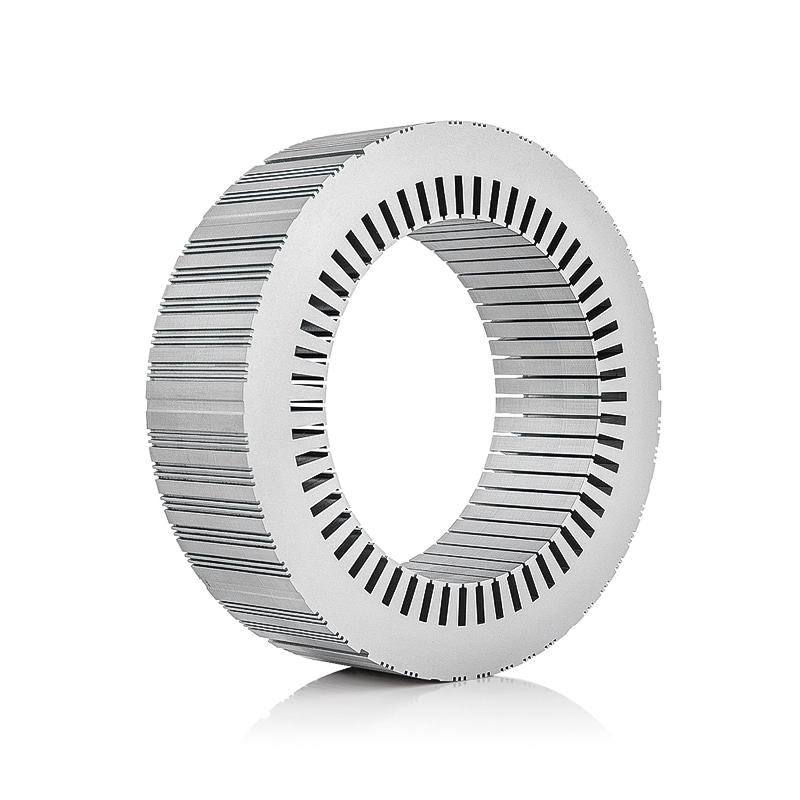

Role of the Stator Windings in Creating a Rotating Magnetic Field

The stator windings are strategically arranged to generate a rotating magnetic field, a core principle in all AC motors. This rotating magnetic field is created when current flows through the stator’s coils, which are typically organized in a three-phase configuration for optimal efficiency and balance. As the current flows through each phase, the magnetic field rotates, creating a synchronized interaction with the rotor core. This rotating magnetic field is crucial for continuous motion in the motor, and it ensures that the rotor is always in alignment with the moving magnetic flux. The torque generated by this interaction is a function of the strength of the stator’s magnetic field, the number of windings, and the amplitude of the current passing through them. Thus, the stator windings are responsible for determining the motor’s torque output and speed regulation, making the design and construction of the windings critical to the motor’s overall performance.

Impact of Stator-Rotor Interaction on Motor Efficiency

Efficiency is greatly impacted by the interaction between the stator windings and rotor core. One major factor is the phenomenon of eddy current losses, which occur when the rotating magnetic field in the stator induces currents within the rotor. These currents, in turn, generate heat that reduces the overall efficiency of the motor. To mitigate these losses, laminated rotor cores are often used to minimize the path for these eddy currents. The flux density within the motor—defined as the amount of magnetic field within the core material—directly impacts how much torque the motor can generate. If the flux density is too high, the rotor core can become magnetically saturated, leading to inefficiencies as the motor struggles to generate additional torque. If the flux density is too low, the motor will not produce enough torque to meet the demands of the application. Optimal efficiency is achieved when the stator and rotor core are carefully designed to ensure proper magnetic flux linkage, minimizing energy loss while maximizing torque and speed capabilities.

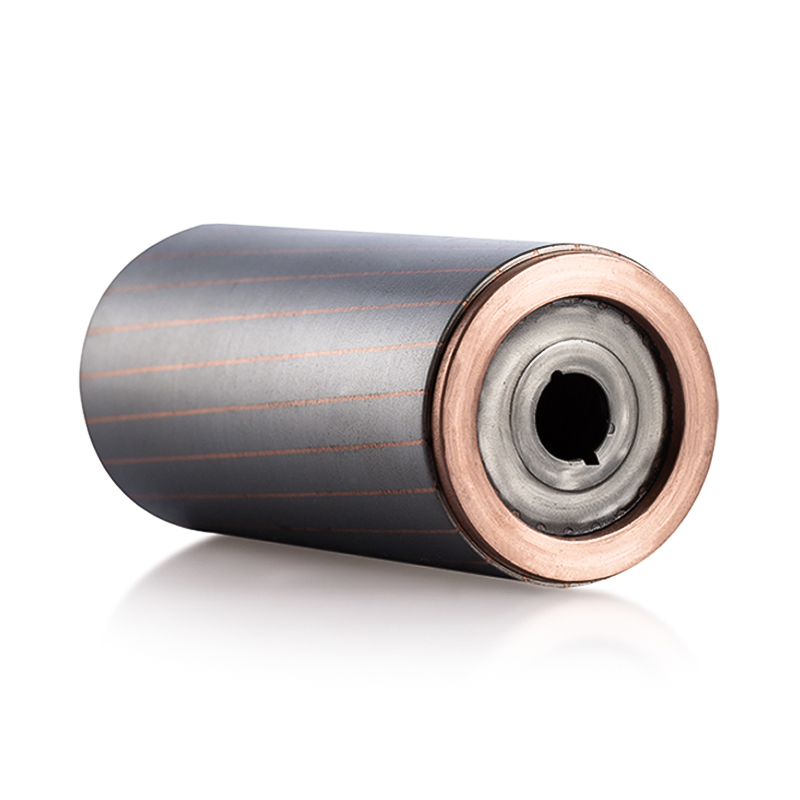

Effect of Rotor Design and Material on Performance

The material and design of the rotor core directly influence how well the rotor interacts with the stator's magnetic field. The rotor is usually constructed from high-permeability materials, such as laminated electrical steel, which help to reduce resistive losses and allow for efficient magnetic flux conduction. The rotor may feature either a squirrel-cage design (in the case of induction motors) or a permanent magnet arrangement (in synchronous motors), each designed to optimize the magnetic interaction with the stator windings. Rotor skewing, which involves slightly offsetting the rotor laminations, is another technique used to reduce harmonic distortion and smooth out the torque production, leading to less vibration and quieter operation. In addition, rotor material quality and construction, such as using copper or high-conductivity alloys, are important in ensuring that the rotor responds efficiently to the stator’s magnetic field. The rotor core must also be designed to withstand the mechanical stresses of rotation at high speeds while maintaining low eddy current losses and thermal expansion, both of which can compromise efficiency.

Implications for Motor Control and Precision

The interaction between the stator windings and rotor core is central to servo motor control and precision. Servo motors are typically closed-loop systems, where real-time feedback from position sensors allows for precise control of the rotor’s position, speed, and torque. This feedback enables the motor to make fine adjustments to its motion, ensuring that the rotor follows the desired trajectory with minimal deviation. The torque and speed generated by the interaction of the stator and rotor are adjusted dynamically based on the feedback signal, which allows the servo motor to excel in applications requiring high precision, such as robotics, CNC machines, and aerospace applications. The rotor's response to changes in the stator’s magnetic field must be instantaneous and smooth, and any delay or friction in the rotor-stator interaction can result in positioning errors or oscillations. The design of both the rotor core and stator windings must be optimized to achieve fast response times while minimizing torque ripple, ensuring smooth, precise motion.

简体中文

简体中文 English

English русский

русский Español

Español