How do the laminations in an Industrial Fan Stator Core affect eddy current losses, magnetic efficiency, and heat generation in industrial fan motors?

Purpose and Function of Laminations in the Industrial Fan Stator Core

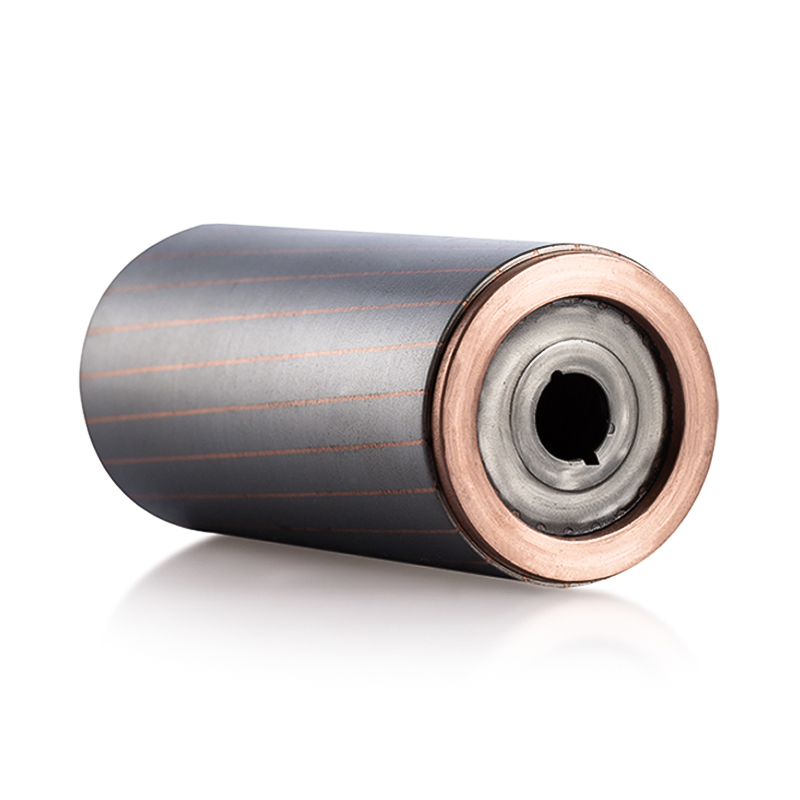

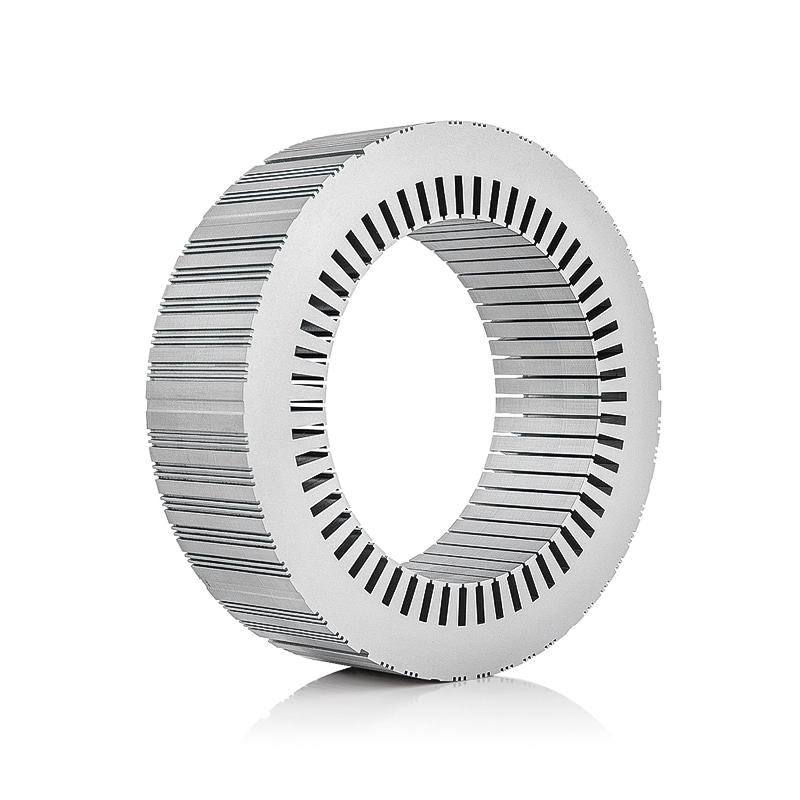

The Industrial Fan Stator Core is a critical component of AC induction and synchronous motors, responsible for generating a magnetic field that interacts with the rotor to produce mechanical motion. Laminations, typically composed of thin, high-grade electrical steel sheets, are stacked to form the stator core. The primary purpose of these laminations is to interrupt the continuous path of induced eddy currents, which naturally arise in conductive materials exposed to alternating magnetic fields. Without lamination, a solid steel core would permit significant circulating currents, generating substantial heat, reducing motor efficiency, and potentially damaging the core or insulation. Each lamination is coated with a thin insulating layer, such as varnish or oxide, which electrically separates the sheets while maintaining high magnetic permeability. This structure ensures that the stator efficiently channels magnetic flux while controlling unwanted electrical currents, optimizing both motor performance and reliability in demanding industrial fan applications.

Reduction of Eddy Current Losses

Eddy currents are localized circulating currents induced in conductive materials by changing magnetic fields, such as those produced in AC-powered industrial fan motors. These currents generate resistive losses, converting electrical energy into heat, which reduces motor efficiency and can increase thermal stress on components. Laminations significantly reduce the cross-sectional area through which eddy currents can flow, thereby limiting their magnitude. The insulating layers between laminations further increase electrical resistance along potential eddy current paths, drastically reducing associated energy losses. By minimizing eddy current flow, laminated cores prevent excessive heating, reduce core losses, and ensure that a larger proportion of input electrical energy is converted into mechanical output. This is particularly important in high-speed or high-frequency fan applications, where unmitigated eddy currents in a solid core could result in substantial power loss, localized overheating, and premature equipment failure.

Improvement of Magnetic Efficiency

The magnetic efficiency of the stator core depends on its ability to conduct magnetic flux from the stator windings to the rotor with minimal energy loss. Laminations improve magnetic efficiency by reducing the opposition caused by eddy currents. With reduced circulating currents, the magnetic flux remains stronger and more uniform throughout the core, resulting in better torque generation and more consistent fan motor performance. Laminated cores also reduce flux leakage and distortion, which are common in solid cores due to induced eddy currents. By maintaining a stable and efficient magnetic path, laminations enable the motor to operate closer to its theoretical efficiency, enhancing energy utilization and reducing operational costs. In industrial fan systems, improved magnetic efficiency translates directly into higher airflow performance, reduced energy consumption, and consistent operational output, which is critical in environments requiring continuous or high-demand operation.

Minimization of Heat Generation

Eddy currents generate heat through resistive (Joule) heating within the stator core material. Excessive heat can degrade insulation, reduce magnetic properties, and accelerate material fatigue, potentially leading to equipment failure. Laminations reduce the magnitude of eddy currents, thus lowering heat generation. Reduced core temperature not only preserves the mechanical and electrical integrity of the stator but also allows the motor to operate at higher efficiency without the need for additional cooling mechanisms. In high-duty industrial fans, which often operate continuously under heavy load, controlling heat is critical to maintaining long-term reliability, preventing thermal expansion-related mechanical stress, and ensuring safe operation. Proper lamination design also helps maintain a stable temperature distribution across the core, avoiding hotspots that could compromise performance or accelerate wear.

简体中文

简体中文 English

English русский

русский Español

Español