How does the Water Pump Motor Stator and Rotor Core contribute to torque stability and smooth startup performance of the water pump motor?

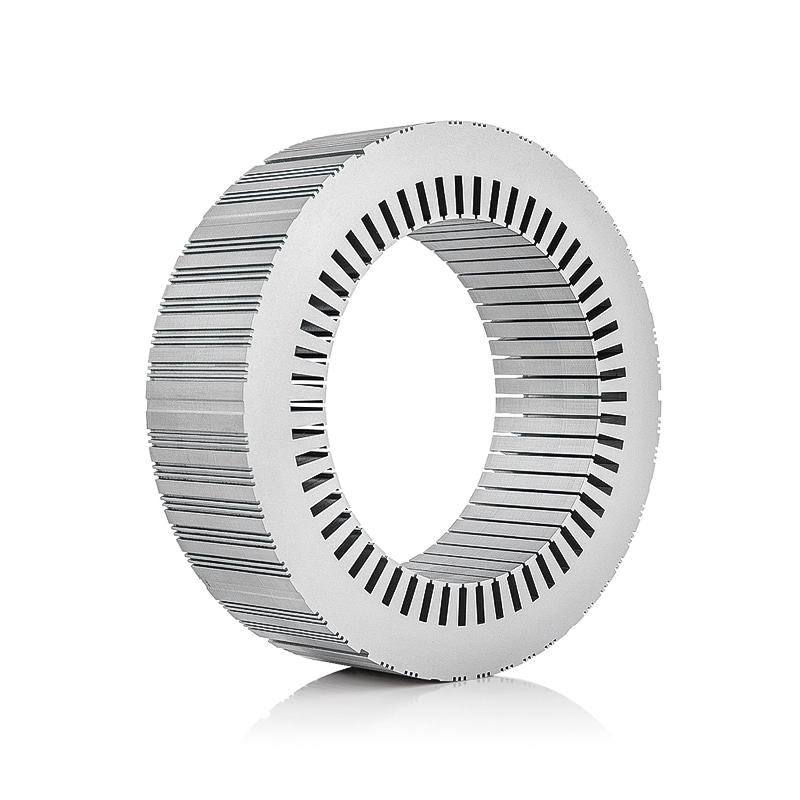

Precision Magnetic Alignment for Uniform Torque

The Water Pump Motor Stator and Rotor Core is meticulously engineered with high-precision laminations and accurately positioned windings to ensure that the magnetic flux generated in the stator interacts optimally with the rotor poles. During startup, when the rotor is stationary and the motor begins to accelerate, the stator generates a rotating magnetic field that induces current in the rotor windings (in an induction motor) or interacts with permanent magnets (in permanent magnet motors). If the stator and rotor are not precisely aligned, flux distribution becomes uneven, resulting in torque ripple, where the motor output fluctuates momentarily. This can lead to mechanical vibration, noise, and uneven water flow. By maintaining exact alignment of stator teeth and rotor laminations, the motor produces smooth, consistent torque from the first moment of rotation, allowing the pump to start gradually without jerking, reducing mechanical stress on bearings and coupling elements.

Optimized Laminated Core Design to Minimize Losses

Both the stator and rotor cores are typically constructed from thin, high-quality silicon steel laminations that are stacked and bonded to reduce eddy current losses and maintain high magnetic permeability. Minimizing these losses is critical because energy dissipated as heat during startup can cause uneven torque generation and reduce efficiency. Laminated cores also reduce hysteresis losses, ensuring that the magnetic field in the cores responds linearly and predictably to the applied current. This design ensures that the motor develops stable and uniform torque even under high inrush currents during startup, providing reliable pump performance and reducing vibration or torque spikes that can damage mechanical components.

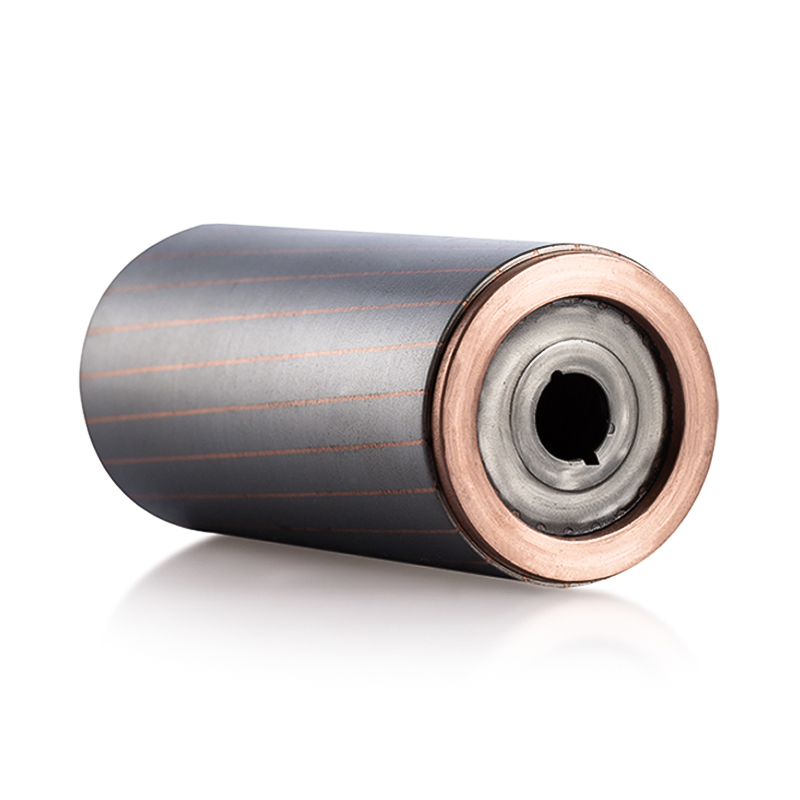

Rotor Inertia and Dynamic Response

The Water Pump Motor Rotor Core is designed with careful consideration of mass distribution and moment of inertia. A rotor that is well-balanced both axially and radially responds smoothly to the rotating magnetic field generated by the stator. This balance prevents sudden surges or stalls during startup, which could otherwise produce torque fluctuations and mechanical vibration. The rotor’s dynamic response is essential in water pump applications, where the fluid load can create variable resistance. By optimizing rotor inertia, the stator and rotor core combination allows for a controlled acceleration curve, minimizing the risk of stress on the pump shaft and bearings while ensuring a smooth increase in flow rate from startup to full speed.

Magnetic Saturation Management

During startup, high currents can produce strong magnetic fields. The stator and rotor cores are designed to operate well below their saturation levels, ensuring linear magnetic behavior. Saturation occurs when the core material cannot support additional magnetic flux, which can result in torque fluctuations, reduced efficiency, and irregular startup behavior. By selecting cores with high saturation flux density and appropriate cross-sectional areas, the motor maintains predictable torque output even under transient high-current conditions. This prevents jerky motion, reduces mechanical stress, and allows the pump to accelerate smoothly while delivering consistent flow rates.

Thermal Stability for Consistent Torque

High inrush currents during motor startup generate heat in the stator windings and core laminations. The Water Pump Motor Stator and Rotor Core uses materials and insulation systems that maintain mechanical and magnetic properties under these thermal loads. Thermal expansion is carefully managed so that the laminations remain aligned and the rotor-stator gap stays uniform, preventing friction or misalignment that could cause torque fluctuations. Thermally stable cores also prevent insulation degradation, ensuring that torque remains consistent and reliable over thousands of startup cycles, which is particularly critical in water pump applications that require frequent start-stop operation.

简体中文

简体中文 English

English русский

русский Español

Español