What are the key performance advantages of using an Electric Vehicle Generator Motor Stator Core compared to conventional stator designs?

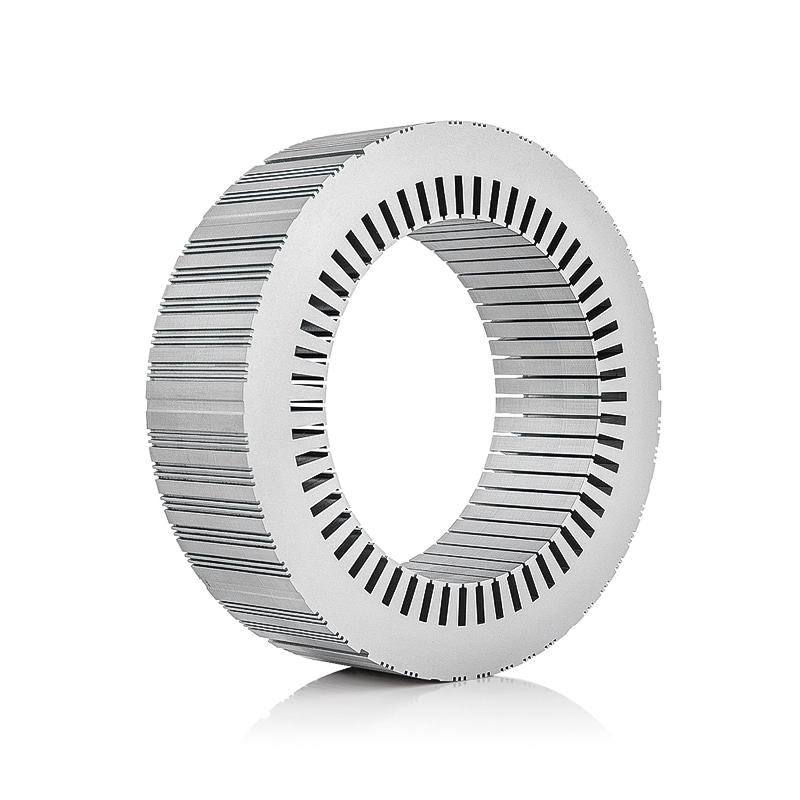

Higher Magnetic Efficiency and Reduced Energy Losses

An Electric Vehicle Generator Motor Stator Core is engineered to optimize magnetic flux pathways and minimize energy losses, which is essential for the high-efficiency demands of electric vehicles. The core is constructed using high-grade electrical steel laminations that are precisely stamped and stacked to reduce eddy current formation. Thinner laminations and advanced stacking techniques lower hysteresis and eddy current losses compared to conventional stator designs. This optimized magnetic efficiency allows the motor to produce higher torque per unit of electrical input, enhancing acceleration and overall vehicle performance. In addition, reduced energy losses translate directly into longer driving ranges, which is a critical performance metric for electric vehicles.

Enhanced Thermal Management and Heat Dissipation

Thermal performance is a key factor in maintaining motor efficiency and reliability. An Electric Vehicle Generator Motor Stator Core is designed with optimal lamination spacing, winding slot geometry, and materials that facilitate effective heat conduction away from the stator. This design ensures uniform temperature distribution across the core, reducing hot spots that can degrade insulation and compromise motor lifespan. By contrast, conventional stator designs often experience uneven thermal profiles, leading to localized overheating, reduced efficiency, and potential failure. Superior thermal management in EV stator cores allows for sustained high-power operation, better performance under peak loads, and improved longevity of the motor.

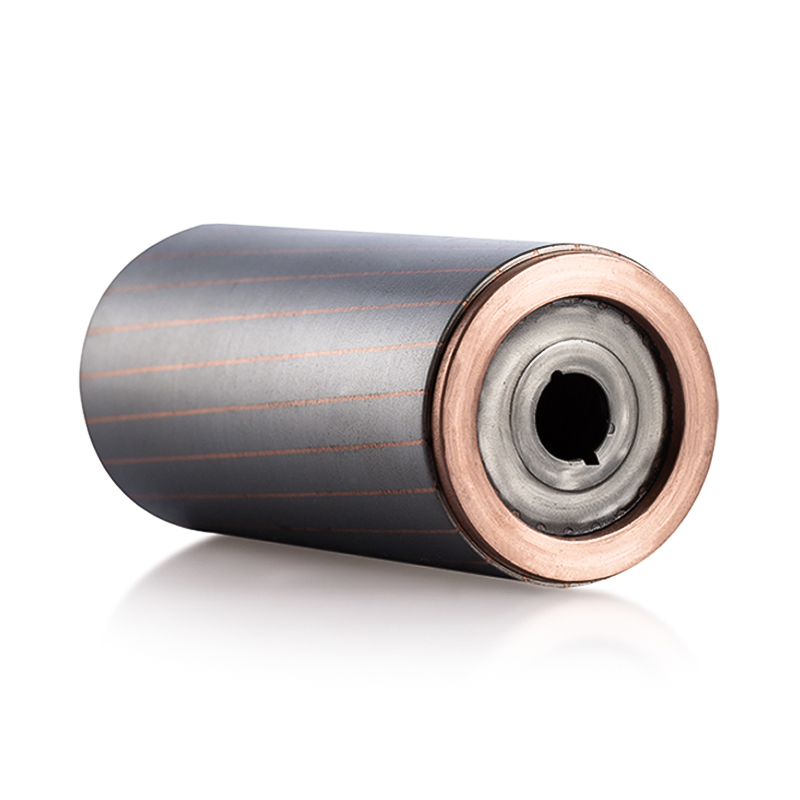

Compact and Lightweight Design for Higher Power Density

Electric vehicle applications require motors that are both compact and lightweight without sacrificing performance. The Electric Vehicle Generator Motor Stator Core is engineered with optimized geometry and materials to achieve high power density. Reduced core mass contributes to lower overall motor weight, improving vehicle efficiency, handling, and acceleration. Conventional stator designs typically require thicker laminations or heavier cores to achieve similar magnetic performance, resulting in larger, bulkier motors. By minimizing material use while maintaining structural and magnetic integrity, EV stator cores provide a compact solution that meets the stringent space and weight constraints of modern electric vehicles.

Optimized Electromagnetic Performance

The electromagnetic design of an Electric Vehicle Generator Motor Stator Core ensures precise control of magnetic flux, reducing flux leakage and enhancing torque uniformity. This reduces torque ripple, vibration, and acoustic noise during operation, resulting in smoother performance and improved driving experience. Conventional stator designs may have suboptimal flux paths, leading to inefficiencies, higher electromagnetic losses, and increased operational noise. The precise flux control in EV stator cores enhances efficiency across varying speeds and loads, allowing electric motors to deliver consistent torque and improved responsiveness.

Improved Compatibility with Advanced Motor Topologies

Modern electric vehicles increasingly employ high-efficiency motor architectures such as permanent magnet synchronous motors (PMSMs) or switched reluctance motors (SRMs). An Electric Vehicle Generator Motor Stator Core is specifically designed to support these advanced topologies, including precise slot geometries, optimized winding configurations, and seamless integration with rotor magnets or salient poles. Conventional stator designs may not provide the precise alignment, magnetic characteristics, or mechanical tolerance required for high-performance EV motors, limiting their efficiency and torque output. EV stator cores enable the implementation of advanced motor topologies that maximize efficiency, performance, and vehicle range.

Long-Term Reliability and Reduced Maintenance

The design features of an Electric Vehicle Generator Motor Stator Core, including minimized core losses, optimized thermal management, and precision manufacturing, contribute to long-term reliability. By reducing thermal and electrical stress on insulation materials and other components, these stator cores minimize the risk of premature failure. Conventional stator designs, with higher losses and less effective thermal management, often experience accelerated degradation and require more frequent maintenance. EV stator cores extend the operational lifespan of the motor, reduce downtime, and enhance overall vehicle reliability.

简体中文

简体中文 English

English русский

русский Español

Español